Company

Our facilities

We produce everything in Italy to provide you with reliable, traceable, and 100% controllable machines.

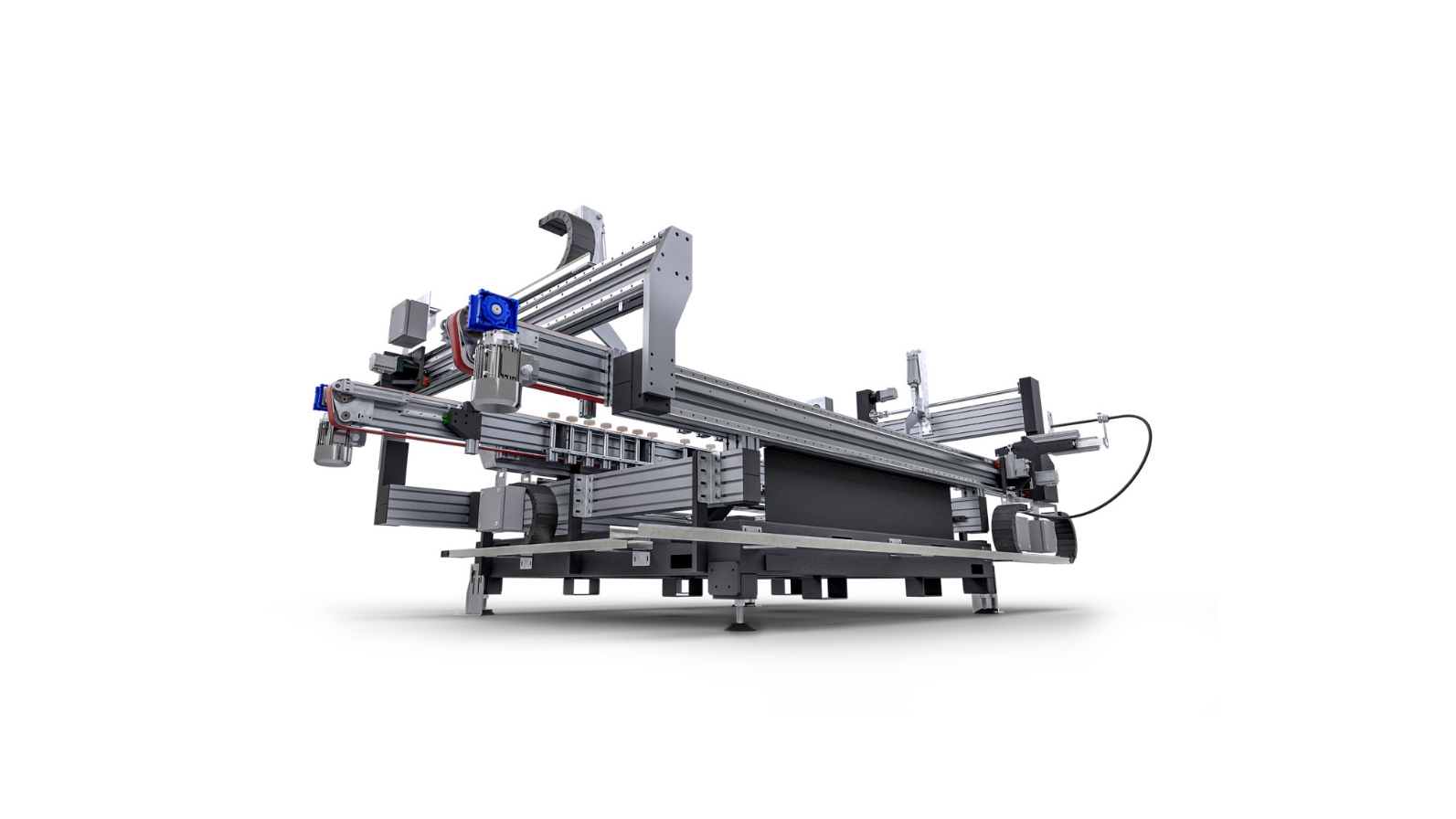

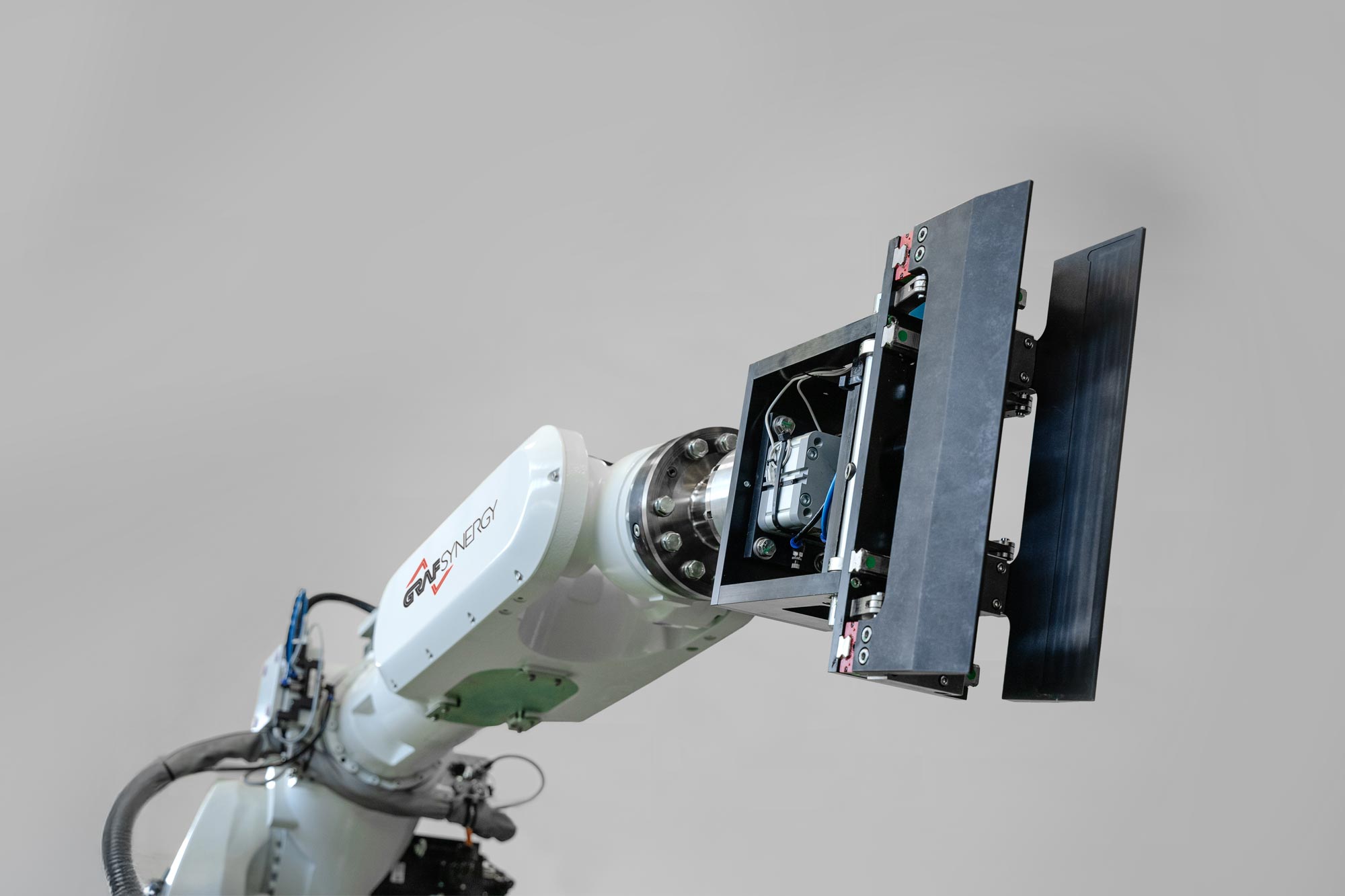

Every machine bearing the GRAF Synergy name is born, developed, and tested within our production facilities in Nonantola (MO), in the heart of Emilia-Romagna. This is a deliberate choice: to maintain complete control over the quality, timing, and technological evolution of each individual component.

Centralising production allows us to be fast, flexible, and responsive, with assembly lines ranging from standard units to fully customised projects. Every machine that leaves our facilities is the result of a fully in-house process, from mechanical engineering to electrical wiring, from software development to commissioning.

Over 12,000 square meters dedicated to industrial innovation

In recent years, we have doubled our production area to meet the growing demand and accommodate new technologies.

Our facilities are divided into:

- Mechanical Assembly and Plant Engineering Area

- Electronic Lab and Software Testing

- Prototyping and R&D Division

- Pre-testing and final testing area

- International Logistics and Shipping Centre

Each department is organised according to lean principles and optimised to ensure efficiency, order, and material traceability. The workstations are monitored and interconnected, fully aligned with Industry 4.0.

Visit the beating heart of our technology

Our facilities are not just production sites; they are spaces for engaging with customers, technical showrooms where you can test machines in real-time, and training centres for operators and installers.

We regularly organise technical demos, scheduled visits, and customised training because we believe that trust begins with transparency: seeing where and how a GRAF Synergy machine is made is the first step in choosing a partner, not just a supplier.