Company

Sustainability

and Certifications

Innovating also means respecting: people, resources, and the environment.

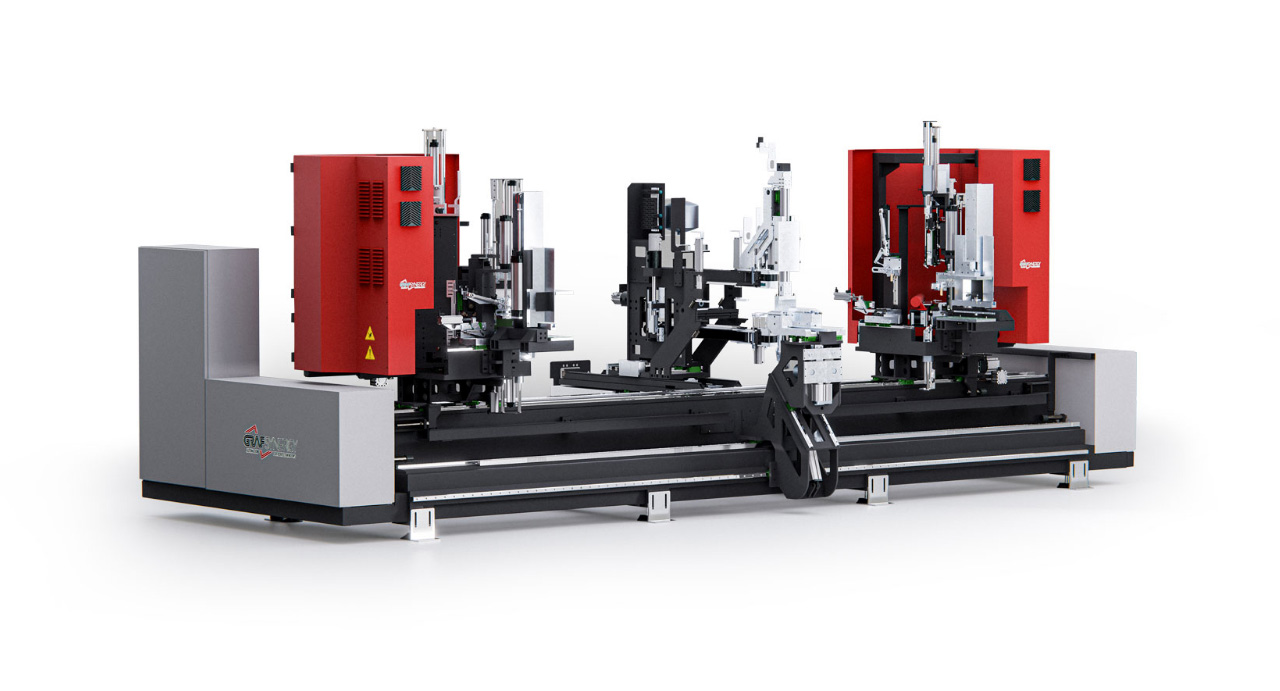

At GRAF Synergy, sustainability is not just a trend; it is a design principle. Every machine, every production line, and every internal process is developed with the aim of reducing waste, increasing efficiency, and improving the quality of working life.

Our focus starts with design: we create systems that use less compressed air, less electricity, and generate less waste. We optimise processes to reduce rework and minimise machine downtime. All of this translates to lower operating costs and a reduced environmental impact for the end customer.

GRAF Synergy / Machines for Perfect Windows

Materials, processes, and people: sustainability from all angles.

In our facilities, we adopt a lean and circular production approach.

Additionally, all our machines are designed to be integrated into Industry 4.0 systems, enabling consumption monitoring and predictive planning.

We use

We use durable and renewable components.

We design

We design for simplified maintenance and extended lifecycle.

We offer

We provide remote assistance and telemonitoring to reduce on-site interventions and travel emissions.

We train

We train operators and technicians for a mindful and optimized use of machines.

Lower operating costs,

reduced environmental impact

Certifications and Recognitions

We are proud to have achieved the Silver Ecovadis rating, one of the most authoritative international certifications in environmental, social, and governance (ESG) sustainability.

Our systems comply with CE standards and machinery safety, and all internal processes meet the criteria for traceable and controlled quality.

We provide our clients with comprehensive technical dossiers to access the incentives of the Transition 4.0 Plan, including documentation, certifications, and consulting support.

Choosing GRAF Synergy means choosing responsible technology.

Today more than ever, sustainability is a key driver of competitiveness. We want to be the right partner for those looking ahead, with products that combine performance and environmental respect.