001BN

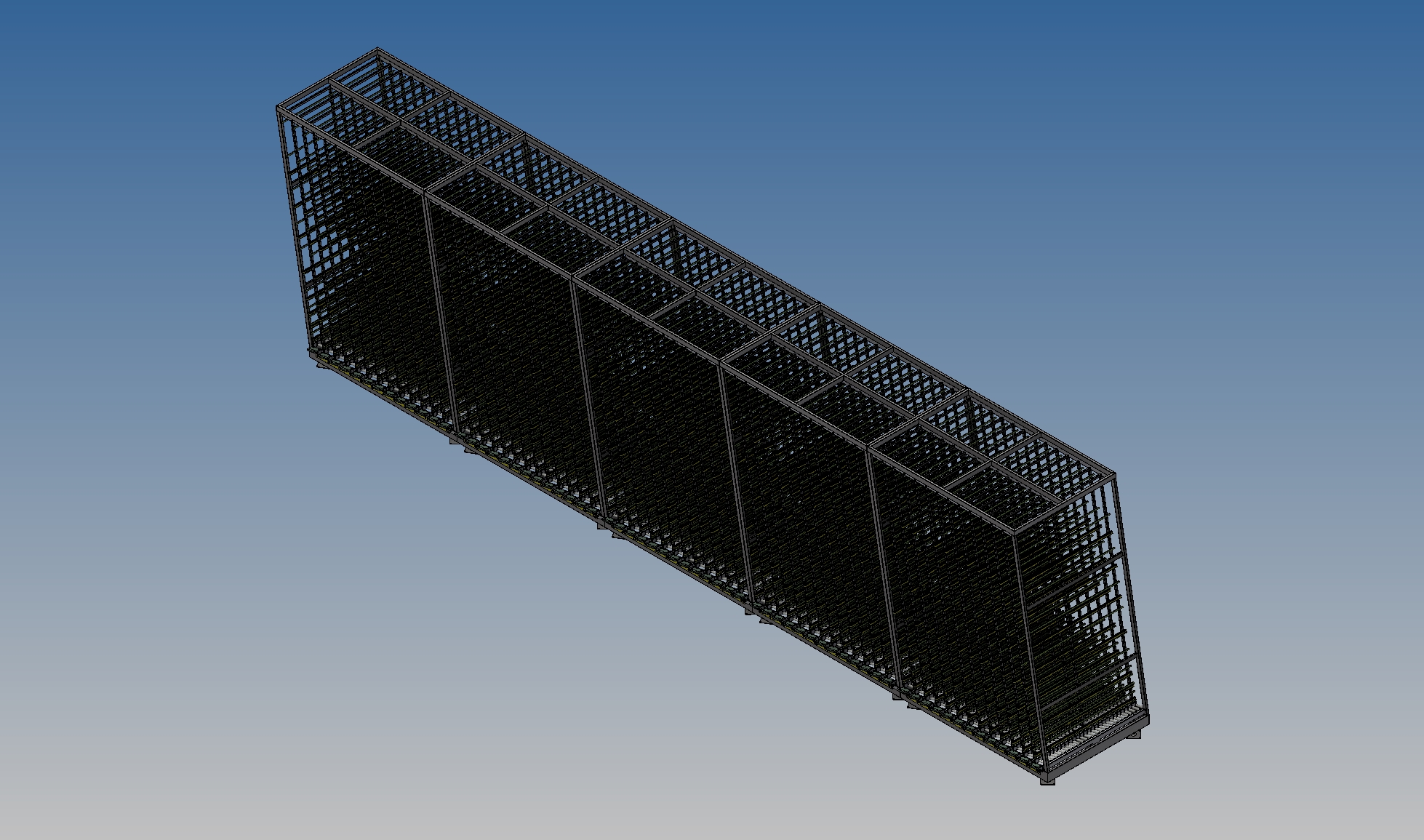

Flip Assembly Table for Door and Frame

Ergonomics and versatility for every stage of assembly

Perfect if:

- Simplify the manual assembly of the door and frame.

- Operate in both vertical and horizontal positions with maximum ergonomics.

- Easily integrate manual workstations into automated lines

- Reduce operator fatigue during the assembly phases.

- Manage operations on large frames

- Having a strong yet versatile structure

Request the technical brochure now or speak with an expert.

Ergonomics and versatility for every stage of assembly

The 001BN workbench is designed to facilitate manual operations for pairing doors/frames and mounting hardware in both vertical and horizontal positions. It serves as an ideal connection point between horizontal automated lines and vertical manual workstations, ensuring stability, safety, and ease of use.

The electro-welded steel structure is equipped with a pneumatic tilting system and a support surface with brushes, while the retractable lower roller conveyor facilitates movement during the working phase.

5 reasons to choose 001BN

- Easy and Safe Pneumatic Tilting. The work surface tilts from horizontal to vertical with pneumatic control, enhancing accessibility.

- Maximum operational ergonomics. The combination of brushes and retractable rollers makes every assembly phase smoother.

- Light yet sturdy structure. Welded steel construction, optimised for stability and ease of handling.

- Adaptable to any layout. Available with variants featuring guide wheels and pneumatic brakes for movement on floor tracks.

- Cost-effective and functional solution. Easy to use, requires no electrical power. Minimal air consumption.

Product Details

The 001BN workbench is designed to facilitate manual operations for coupling doors/frames and mounting hardware in both vertical and horizontal positions. It is ideal as a connection point between horizontal automated lines and vertical manual workstations, ensuring stability, safety, and ease of use.

The electrowelded steel structure is equipped with a pneumatic tilting system and a support surface with brushes, while the retractable lower roller conveyor facilitates movement during the working phase.

Sizes

Length: 3,500 mm

Width: 2,100 mm

Height: 2,380 / 2,500 mm*

Weight: 240 kg

(height adjustable upon request)

Performance

Operators required: 1

Operation: manual

Flipping: tyre

POWER Supply and Consumption

Installed power:

Tension: unexpected

Air consumption per cycle: 50 NI/min

Operating pressure: 7 bar

Manageable profiles (frame sizes)

Maximum length: 3,500 mm

Max width: 2,100 mm

Supported features and processes

- Fitting hardware on the door leaf and frame

- Pairing elements in vertical and horizontal positions

- Connection between automatic and manual lines

- Support plan with brushes

- Retractable support roller

- Pneumatic tipping system

Optional features and available configurations

The bench can be customized with:

- Accessory drawer

- Pneumatically collapsible lower roller

- Structure with wheels and pneumatic brake (operable by pedal or manually)

These solutions allow for the optimisation of the workspace and the adaptation of the bench to dynamic layouts.

TECHNOLOGY AND AUTOMATION

Essential yet functional, the 001BN operates with pneumatic actuators without the need for electrical power. Perfect for integration into manual workstations, it can be easily moved or repositioned thanks to its mobile versions, making it a flexible ally in finishing and quality control processes.

Contact us to find out if the 001BN is the right solution for your production.