001TN

Automatic Vertical Stacking Machine for Welding and Assembly Lines

Simplify handling, improve flow

Perfect if:

- Automatically verticalize welded frames after welding.

- Join non-parallel lines within production.

- Reduce the physical effort of operators

- Optimize the cycle time of subsequent machines

- Working safely and with a continuous flow

- Easily adapt the bench to existing or compact lines.

Request the technical brochure now or speak with an expert

Simplify the handling, improve the flow

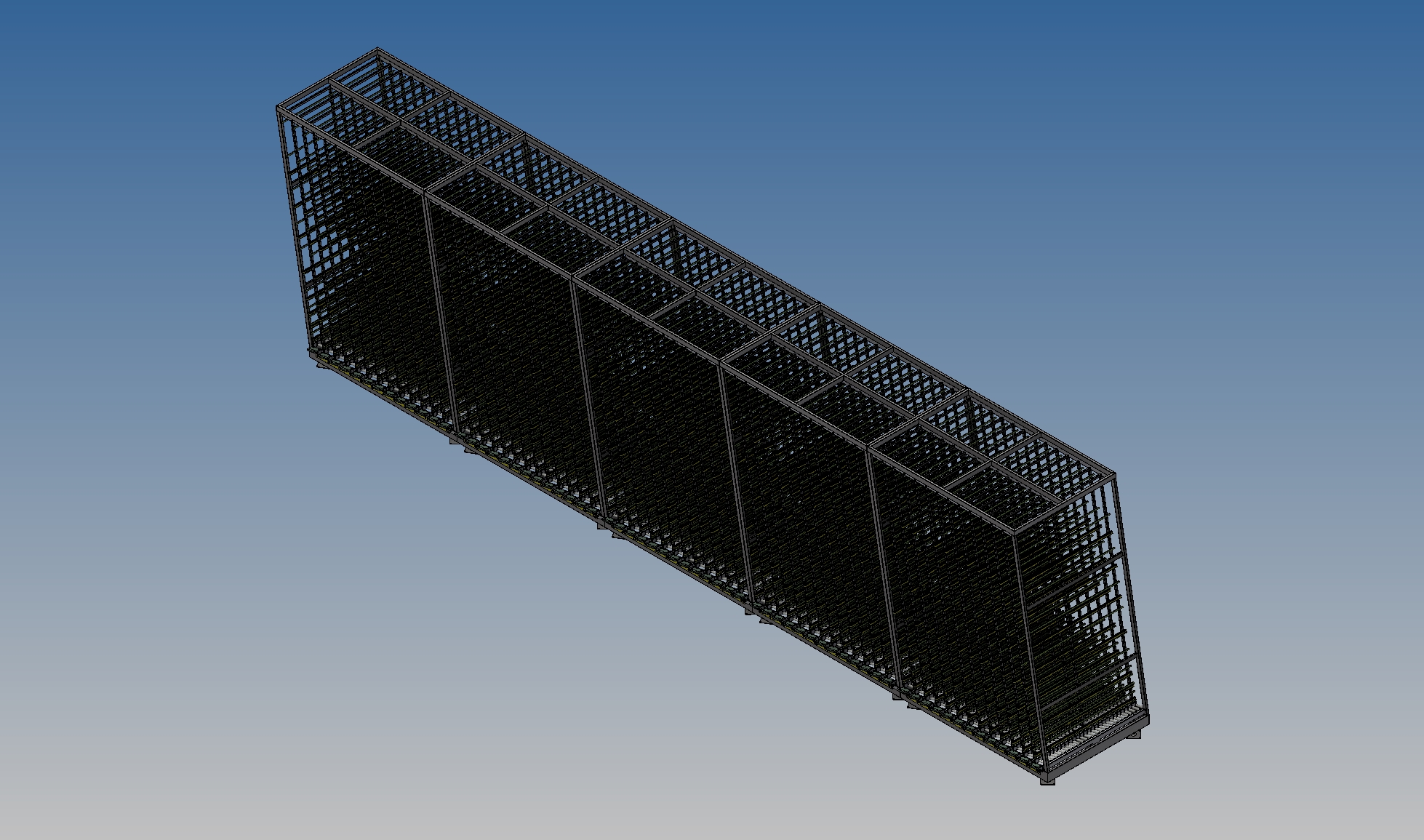

The 001TN verticalising bench is Graf Synergy’s solution for optimising the vertical arrangement of welded frames within the production line. It can be positioned either downstream of the welding machine or as a junction point between non-parallel lines, allowing for the automatic and safe tilting of elements from 0 to 80°, minimising the need for manual intervention.

Its compact structure and contact surface designed to prevent blockages during movement make it ideal for production environments with limited space or customised layouts.

5 reasons to choose 001TN

- Controlled and precise tilting. Motorised brushless or pneumatic system that enables automatic verticalisation from 0 to 80°.

- Low Friction Surface. Polyurethane belts with thermally welded guide profiles and diagonal brushes ensure smooth movement of the panels.

- Compact and modular structure. Made from welded and painted steel tubing, it is sturdy yet compatible with both linear and complex layouts.

- Maximum safety at every stage. Equipped with vertical straps, side rollers, and guards that keep the fixture stable even during inversion.

- Customisable for every need. Available in five versions up to 6,000 mm in square length to fit any production format.

Product Details

001TN enables the automatic transfer and verticalisation of frames, streamlining internal logistics between welding, storage, and assembly.

Sizes

Length: 3,500 mm

Width: 3,400 mm

Height: 1,000 mm

Weight: 1.600 kg

Performance

Cycle time: depends on the connected system

Operators required: 1

Automatic tilt from 0 to 80°

power supply and Consumption

Installed power: 10 kW

Voltage: 400 V

Air consumption per cycle: 30 NI/min

Operating pressure: 7 bar

Manageable profiles (frame sizes)

Maximum length: 2,800 mm

Max width: 1,400 mm

Maximum thickness: 130 mm

Supported features and processes

- Polyurethane straps with heat-sealed guide

- Anti-jam diagonal brushes

- Horizontal conveyor with inverter

- Floating bed with crazy wheels/brushes

- Side vertical rollers and support tracks

Optional features and available configurations

There are no optional features available. However, it is offered in various sizes to fit larger frames.

- 001TN40: 2,800 x 4,000 mm

- 001TN32: 2,800 x 3,200 mm

- 001TN34: 4000 x 3200 mm

- 001TN60: 2,800 x 6,000 mm

- 001TN50: 2,800 x 5,000 mm

Technology and Automation

The 001TN is powered by high-efficiency brushless motors or a pneumatic system, combining reliability with ease of operation. The inverter control on the conveyor allows for dynamic adjustments to handling speed. Integratable with Industry 4.0 systems, it can be connected to management software for cycle synchronization and flow optimization.

Contact us to find out if the 001TN is the right solution for your production.