002NV

Vertical Lifter for Automated Assembly Lines

Move with precision, stand tall with confidence

Perfect if:

- Automate the flow between welding, assembly, and tool storage.

- Speed up operations while reducing the risk of errors or damage.

- Manage vertical and horizontal transitions with a single solution.

- Operate safely even in the event of sudden stops.

Request the technical brochure now or speak with an expert.

Move with precision, stand tall with confidence

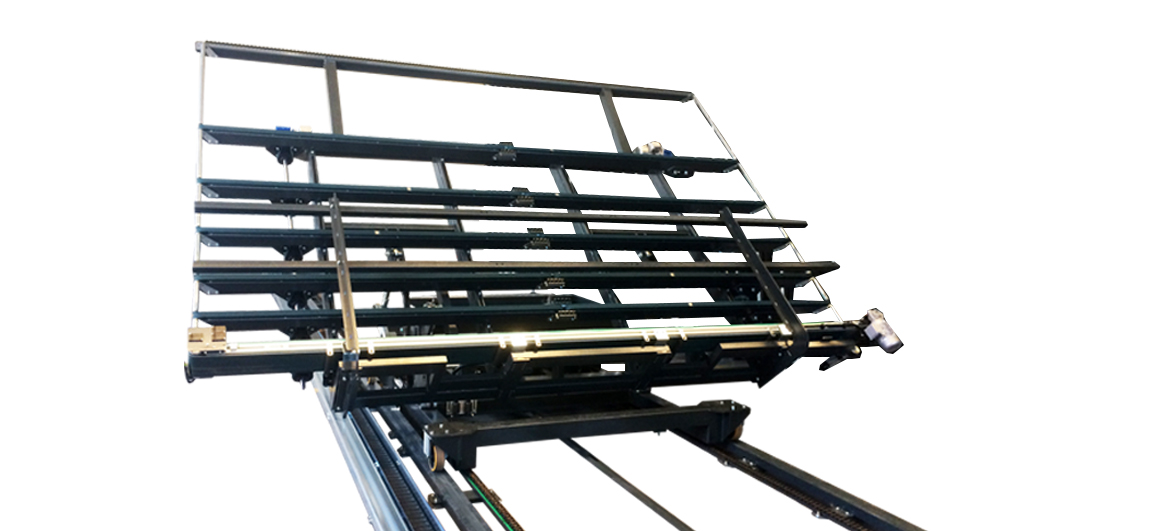

The 002NV from Graf Synergy is an autonomous shuttle designed to optimise the loading and unloading of welded frames between different stations on the production line. With its ability to precisely orient elements from horizontal to vertical (and vice versa), it eliminates interruptions and manual handling, enhancing both efficiency and safety.

Compact yet powerful, the 002NV operates with translation speeds of up to 2 m/s and millimetre tolerances, seamlessly integrating into automated systems even in tight spaces.

5 Reasons to Choose 002NV

- Precise and Automatic Verticalization. Servo-assisted system with brushless technology that adjusts the frame from 0 to 92° (optional 98°) with an accuracy of 0.1°.

- Fast and Smooth Translation. Movement up to 2 m/s with a repeatability of 0.5 mm. The belt and brush contact surface ensures continuous gliding.

- Integrated Safety. Active anti-fall front protections even during emergency stops. Side rollers for centring in horizontal passages.

- Total integration. Manages incoming items from horizontal tables or vertical conveyors. Compatible with automated warehouses and sorting logic.

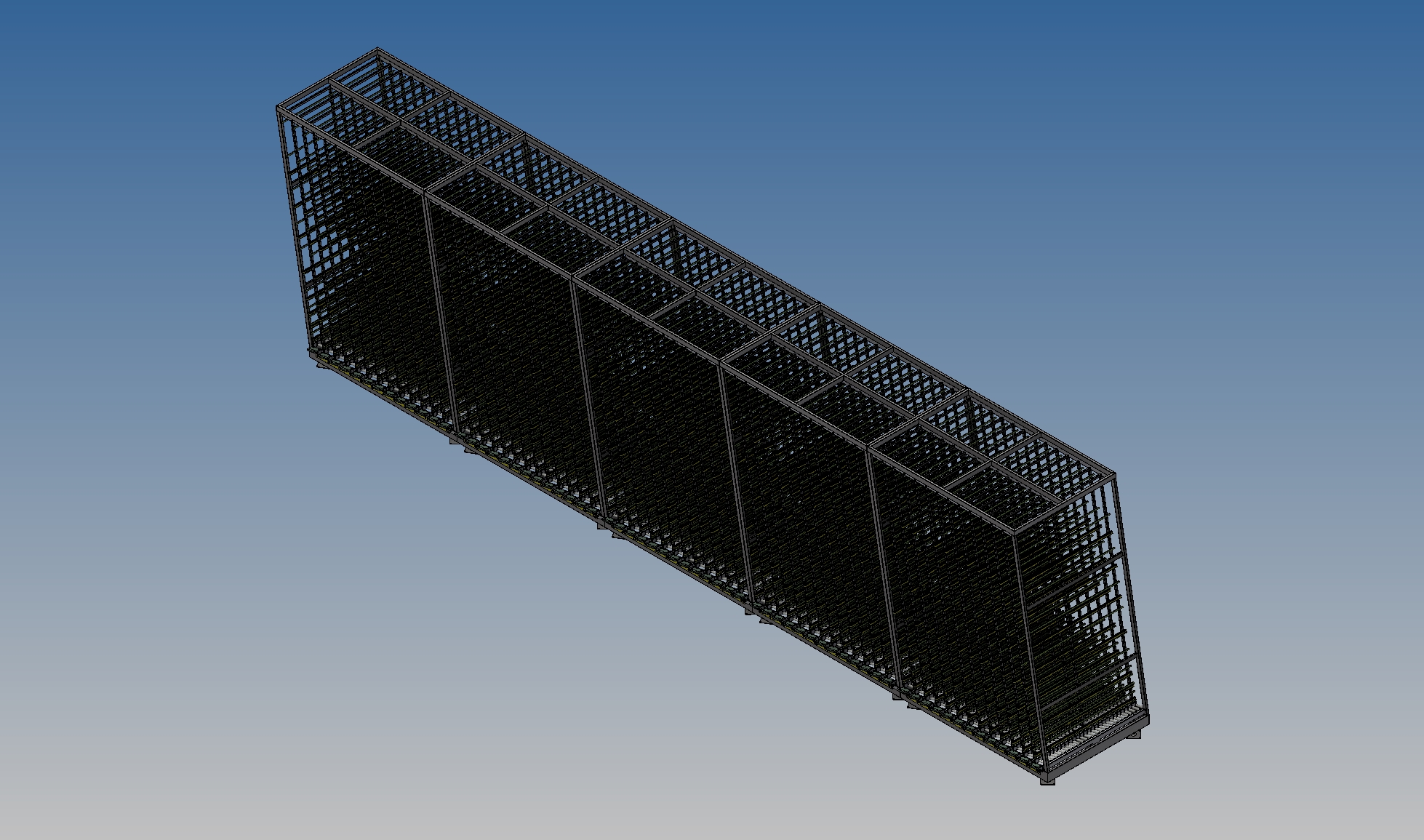

- Ideal for any layout. Compact, sturdy, and oven-painted structure. Perfect for custom lines and modular logistics systems.

Product Details

The 002NV shuttle is designed for the automatic transfer of welded frames between production stations with a change in orientation. Thanks to its polyurethane belt structure, side rollers, and conveyor belt at the base, it ensures:

Sizes

Length: 3,400 mm

Width: 3,500 mm

Height: 3,300 mm

Weight: 1.300 kg

Performance

Average cycle time (loading + transport + unloading): 50 sec*

Translation Speed: up to 2 m/s

Operators required: 1

POWER SUPPLY and Consumption

Installed power: 12 kW

Voltage: 400 V

Air consumption per cycle: 30 NI/min

Operating pressure: 7 bar

Manageable profiles (frame sizes)

Maximum length: 2,800 mm

Max width: 1,400 mm

Max thickness: 130 mm

Supported features and processes

- Loading and unloading on tables or roller conveyors

- Transfer between horizontal and vertical

- Controlled push towards racks or storage areas

- Alignment and centering of frames

- Seamless management of mixed flows

Optional features and available configurations

The 002NV is highly customizable based on production layout and handling requirements. Among the options available:

- Vertical adjustment up to 98° (instead of 92°)

- Assisted handling hook for the panel

- Gravity-based extraction system for warehouses

- Rack and pinion system for conveyor belt transmission in the warehouse

These solutions make it adaptable to complex contexts with FIFO logic, buffering, or integration with existing systems.

TECHNOLOGY AND AUTOMATION

Equipped with high-precision brushless motors and inverters for dynamic speed control, the 002NV shuttle seamlessly integrates into automated Industry 4.0 systems. Management can be connected to supervisory software and ERP systems for frame traceability and synchronization with other stages of the line. Its modular architecture allows for future upgrades and on-demand customizations.

Contact us to find out if the 002NV is the right solution for your production.