005NV

Vertical Shuttle with Rotation for Smart Window Logistics

Precision and versatility for integrated handling

Perfect if:

- Optimize the flow between assembly, glazing, and storage.

- Managing complex frame rotations in tight spaces

- Serve mirrored lines or parallel systems

- Minimise manual operations between each phase.

- Working safely even with large doors

- Adapting logistics to different production formats

Request the technical brochure now or speak with an expert.

Precision and versatility for integrated handling

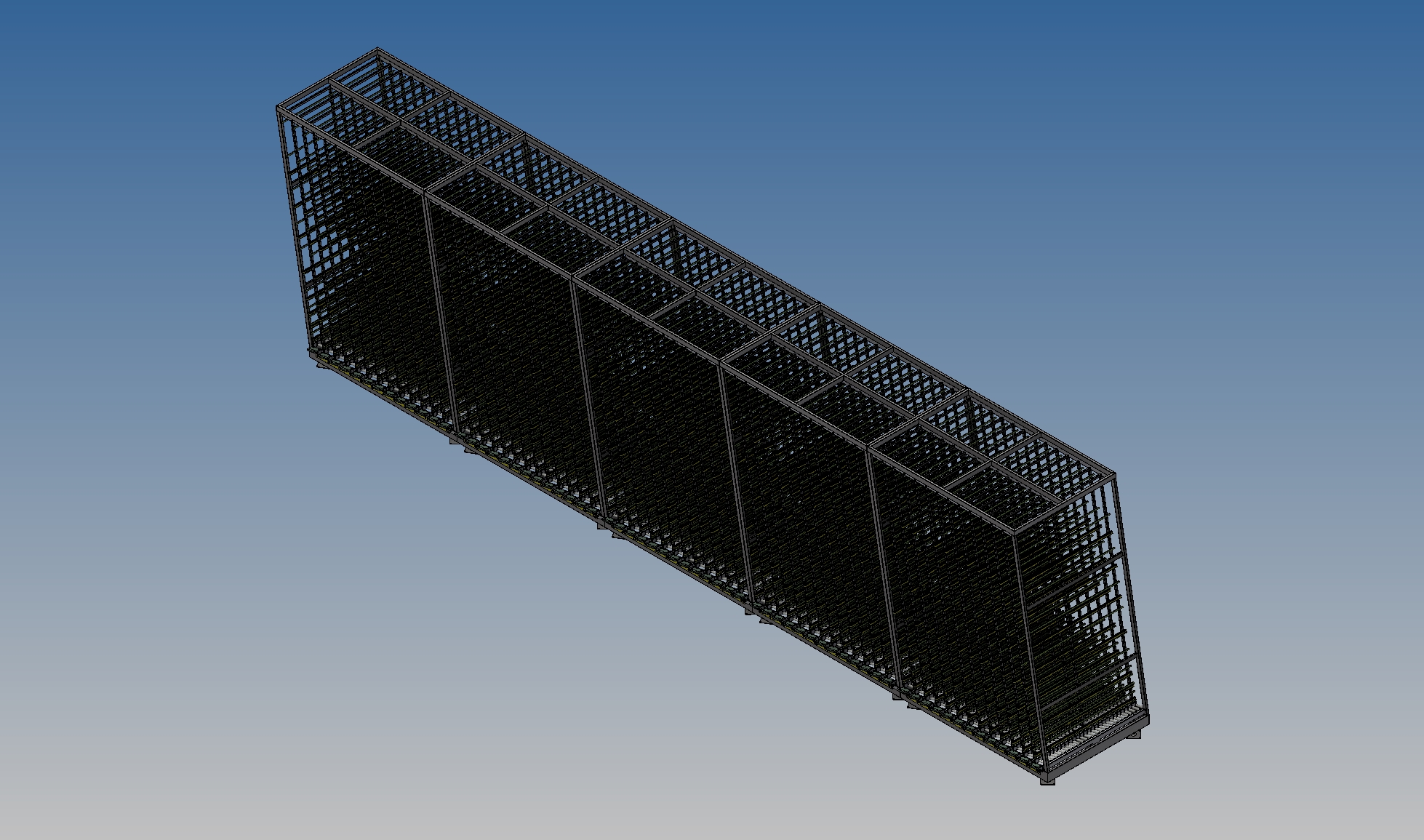

The 005NV is Graf Synergy’s most comprehensive shuttle for the automated handling of panels, frames, and finished windows. With its rotating system, it can rotate pieces by ±180°, adapting them to the orientation required by different production stages, optimising workflows and reducing manual handling.

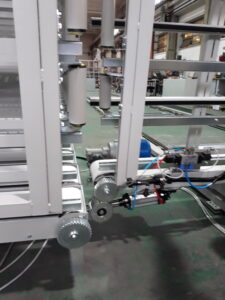

Made of painted steel, with an 8° inclined structure for stable support, it combines rapid translation (up to 2 m/s) with high precision (0.5 mm in translation and 0.1° in rotation).

5 Reasons to Choose 005NV

- Automatic rotation ±180°. Servo-assisted system for changing the orientation of frames with extreme precision and speed.

- Maximum smoothness in transitions. Thanks to side rollers, caster wheels, and a motorised belt with an inverter, every transfer occurs seamlessly without interruptions or misalignments.

- High Mission Speed. Average complete cycle in 45 seconds, optimised for high-intensity production lines.

- Integrated safety for every situation. Front anti-fall protections and an inclined structure ensure stability even in the event of a sudden stop.

- Complete layout flexibility. Supports mirrored configurations and is available in an enlarged version up to 4,000 x 3,200 mm.

Product Details

005NV is the ideal solution for the automatic transfer and rotation of frames between different production stations.

Sizes

Length: 1,900 mm

Width: 3,600 mm

Height: 3,000 mm

Weight: 950 kg

Performance

Average cycle time (loading + transport + unloading): 45 sec*

Translation Speed: up to 2 m/s

Strongly required operators: 1

Element Rotation: ±180

(depends on the length of the line)

POWER SUPPLY and consumption

Installed power: 10 kW

Voltage: 400 V

Air consumption per cycle: 30 NI/min

Operating pressure: 7 bar

Manageable profiles (frame sizes)

Maximum length: 3,200 mm

Maximum width: 2,800 mm

Max thickness: 130 mm

Supported features and processes

- Loading/unloading on roller conveyors or powered storage systems

- Automatic rotation ±180° on the vertical axis

- Smooth transition between different orientations

- Lateral centering using rollers

- Translation on tracks using high-capacity wheels.

Optional features and available configurations

Configurable to suit any layout requirement, the 005NV can be equipped with:

- Pinion system for drive transmission to warehouse conveyors

- Panel handling straps

- Enhanced version 005NV40 (4000 x 3200 mm)

These options extend its use to systems with high volumes or non-standard formats.

TECHNOLOGY AND AUTOMATION

Equipped with a high-precision brushless motor for translation and a servo-assisted rotation system, the 005NV seamlessly integrates with Industry 4.0 systems. The conveyor belt with an inverter allows for dynamic adjustments, while integration with management software and supervisory systems ensures full traceability and centralized logistics management.

Contact us to find out if the 005NV is the right solution for your production.