ASW

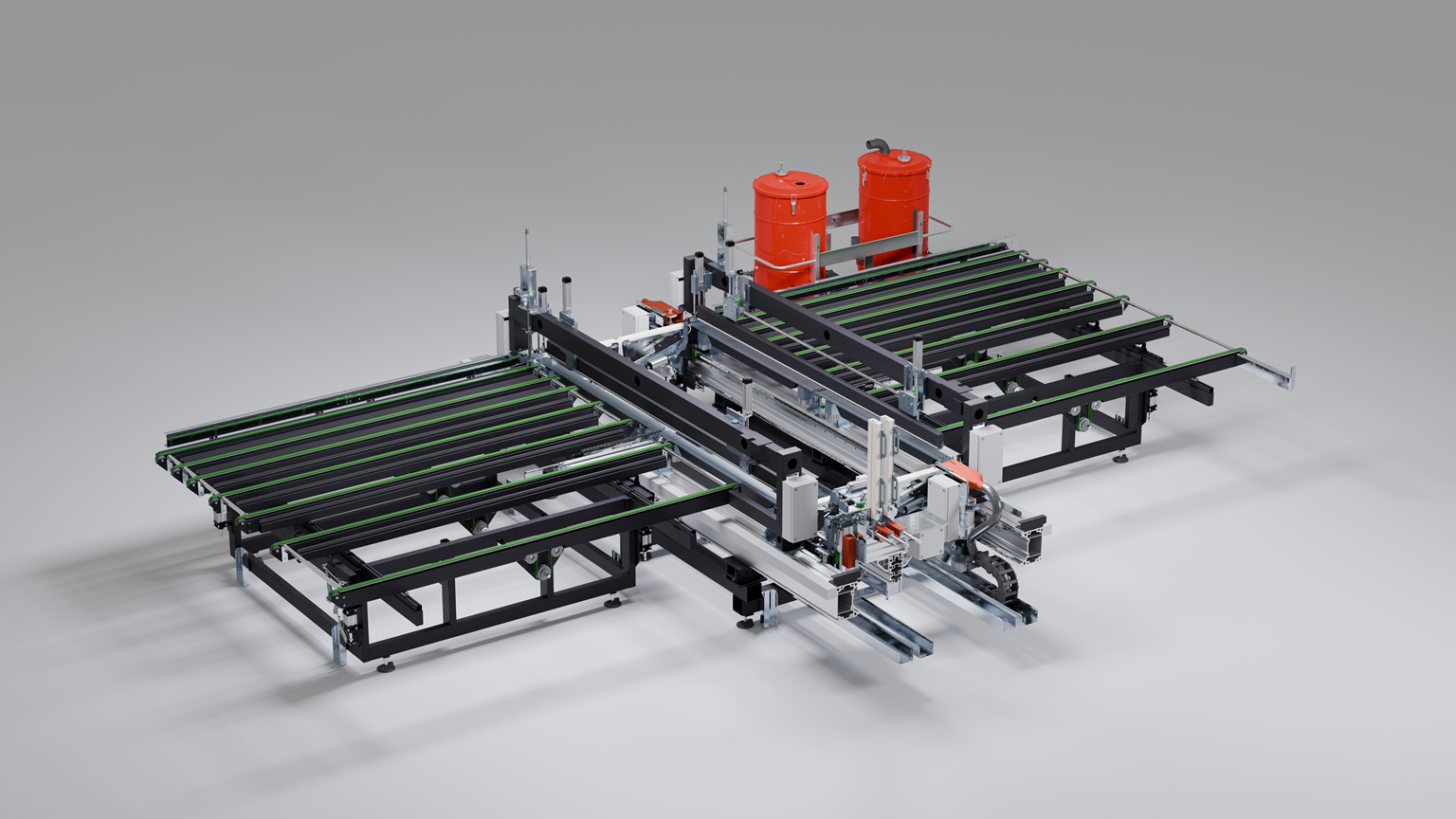

Automatic table for hinge assembly and corner milling of doors.

Maximum precision in hardware assembly: automates drilling and milling after welding

Perfect if…

- Do you want to automate the assembly of hardware on welded doors?

- You need to mill the external corners after welding.

- You also work with Anuba hinges (French market).

- You need a compact machine for two integrated phases.

- Do you want to optimize the flow between the welder and the FAZ bench?

Request the technical brochure now or speak with an expert.

Maximum precision in hardware assembly: automate drilling and milling after welding.

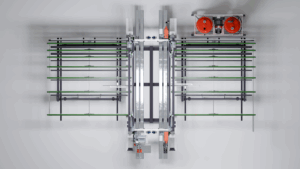

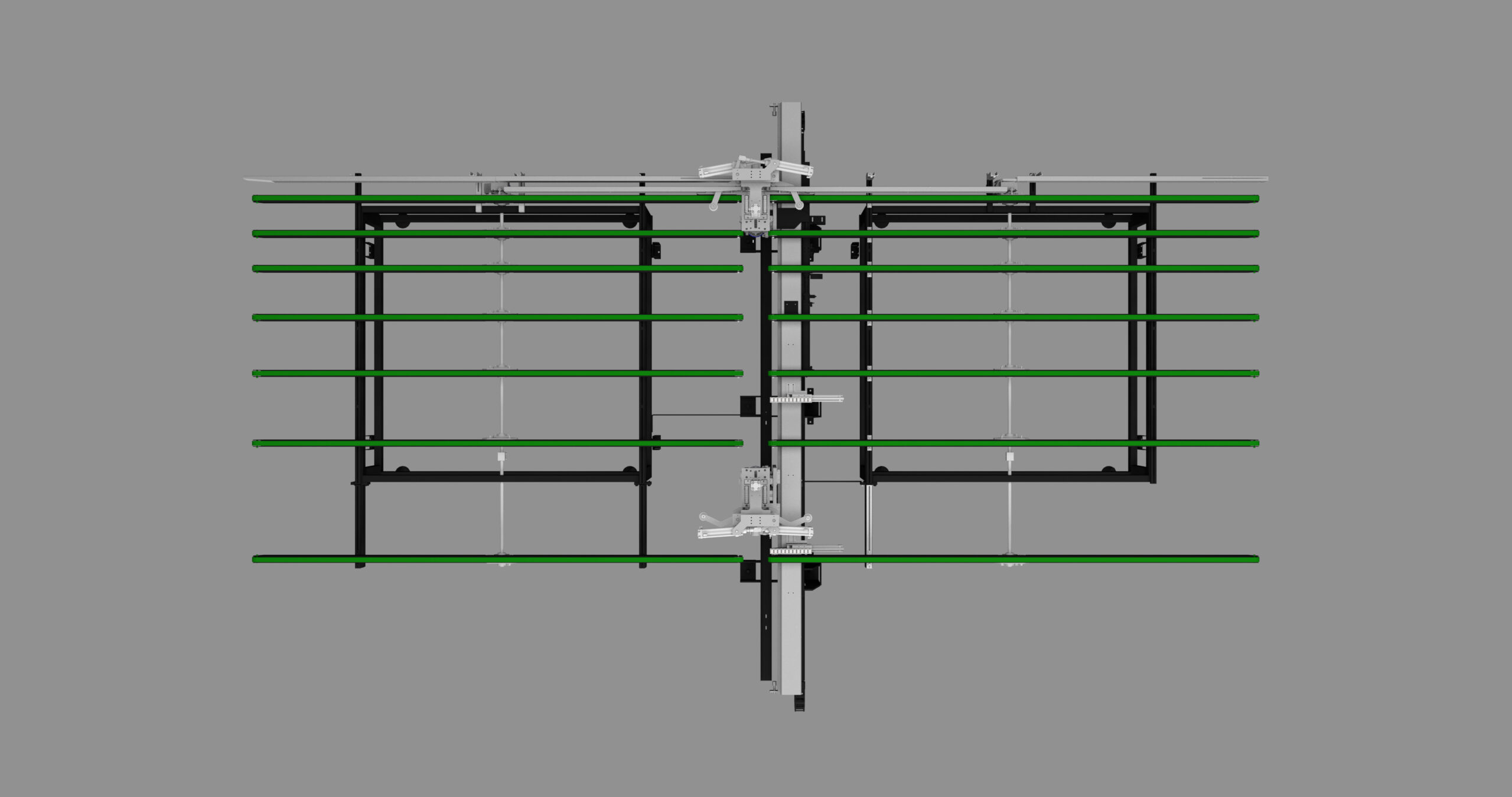

ASW is the automatic table designed by GRAF Synergy to automate two critical phases of PVC door production: the drilling and hinge assembly (including anuba type for the French market) and the milling of the two corner exchange stops generated by the welding of the three door profiles with the reduced door.

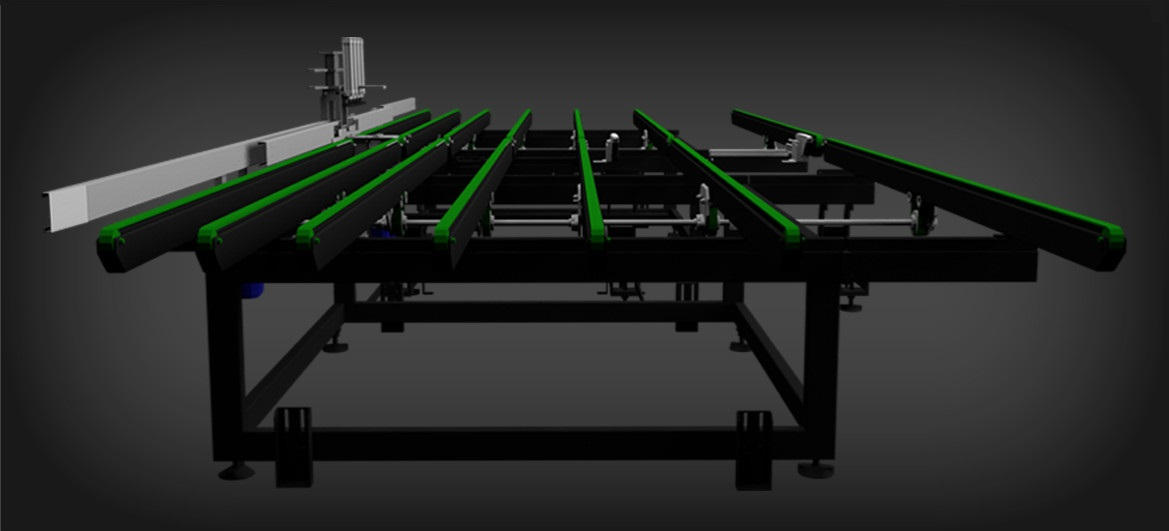

Thanks to a solid steel structure and a scratch-resistant work surface with transport straps, ASW enables high-precision processing on complete doors, reducing errors and increasing efficiency.

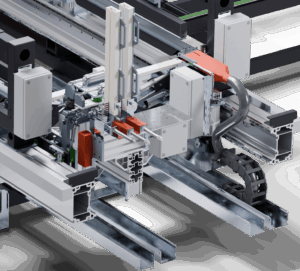

The cycle is fully automated: from gripping to positioning, from processing to release, every stage is managed by an intelligent system that features pneumatic jaws and automatic reference plane measurement.

5 reasons to choose ASW

- Integrated double processing. One machine performs drilling, hinge assembly, and corner milling, reducing movement and enhancing productivity.

- Guaranteed repeatable accuracy. Automatic measurement of the reference plane ensures perfect centring and consistent machining on every piece.

- Compatible with any door leaf. Works with hinged or tilt-and-turn doors, using either traditional or anuba hinges, including on combined frames.

- Fully automated cycle. Automatic internal handling between stations and pneumatic locking for stability during every phase.

- Seamless integration into the production workflow. Positioned between SL4-FF EVO and FAZ workbench, it enables the complete production of finished doors in just 3 steps.

Product Details

ASW is the automatic table designed by GRAF Synergy to automate two critical phases of PVC door production: the drilling and hinge assembly (including anuba type for the French market) and the milling of the two corner exchange stops generated by the welding of the three door profiles with the reduced door.

Sizes

Length: 4,000 mm

Width: 1,400 mm

Height: 3,500 mm

Weight: 1.200 kg

Performance

Operationality: fully automated

Operators needed: 1 (for loading hinges/anuba)

Working frame dimensions:

- Minimum: 400 x 400 mm

- Max: 110.2 x 63.0 inches

POWER SUPPLY and Consumption

Installed power: 18 kW

Power Supply: 400 V

Minimum operating pressure: 8 bar

Air consumption: 500 Nl/min

Supported features and processes

ASW is designed to automate the preparation of the welded panel by performing two essential processes:

- Automatic drilling for hinge and awning windows

- Hinge installation, including anuba type

- Corner milling of the exchange stop after welding

- Automatic centering using a reference plane

Automated internal handling between processes

Optional and configurations

ASW can be customized to fit any production context.

- Anuba hinge form

- Configuration for combined frames

- Customization of the cycle and plan based on the profile type

All configurations ensure the same accuracy and repeatability, even in high-volume production.

Technology and automation

Equipped with GRAF Synergy electronics, ASW integrates:

- Pneumatic jaws for secure gripping and locking

- Automatic reference plane measurement sensors

- Job Management Software and Automated Transitions

Designed for interconnection with Industry 4.0 systems, it integrates into digital lines with centralized control and traceability.

Do you want to make drilling the doors faster and more precise?

Download the brochure to discover all the technical details and available configurations. Contact us for a tailored quote or to arrange a live or remote demo of the HDHS system. Our team is here to help you integrate this solution into your production line.