BM AS CNC

Multi-function automatic machine for the installation of PVC shutters and blinds.

Custom Automation for Shading Systems: Precision, Versatility, and Ease of Operation in a Single CNC Workstation

Perfect if…

- You need to drill and install hinges on large PVC blackout panels.

- Do you want to reduce the operator’s manual workload and increase accuracy?

- Are you working with profiles of varying shapes and sizes and looking for a versatile solution?

- You need to integrate the workstation into your production management system.

- Are you looking for a sturdy, modular, and easy-to-maintain machine?

Request the technical brochure now or speak with an expert.

Custom Automation for Shading Systems: Precision, Versatility, and Ease of Operation in One CNC Machine

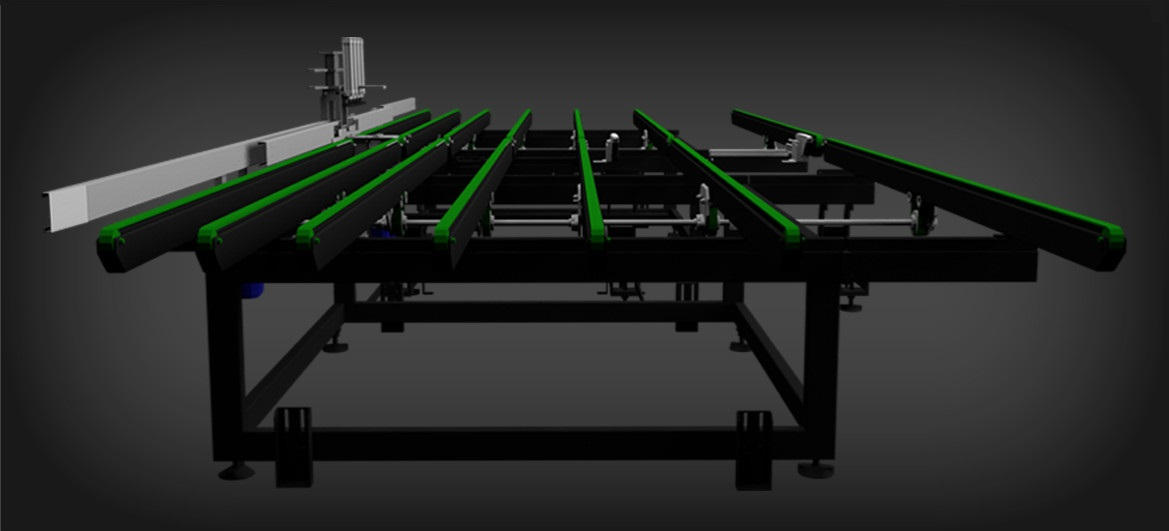

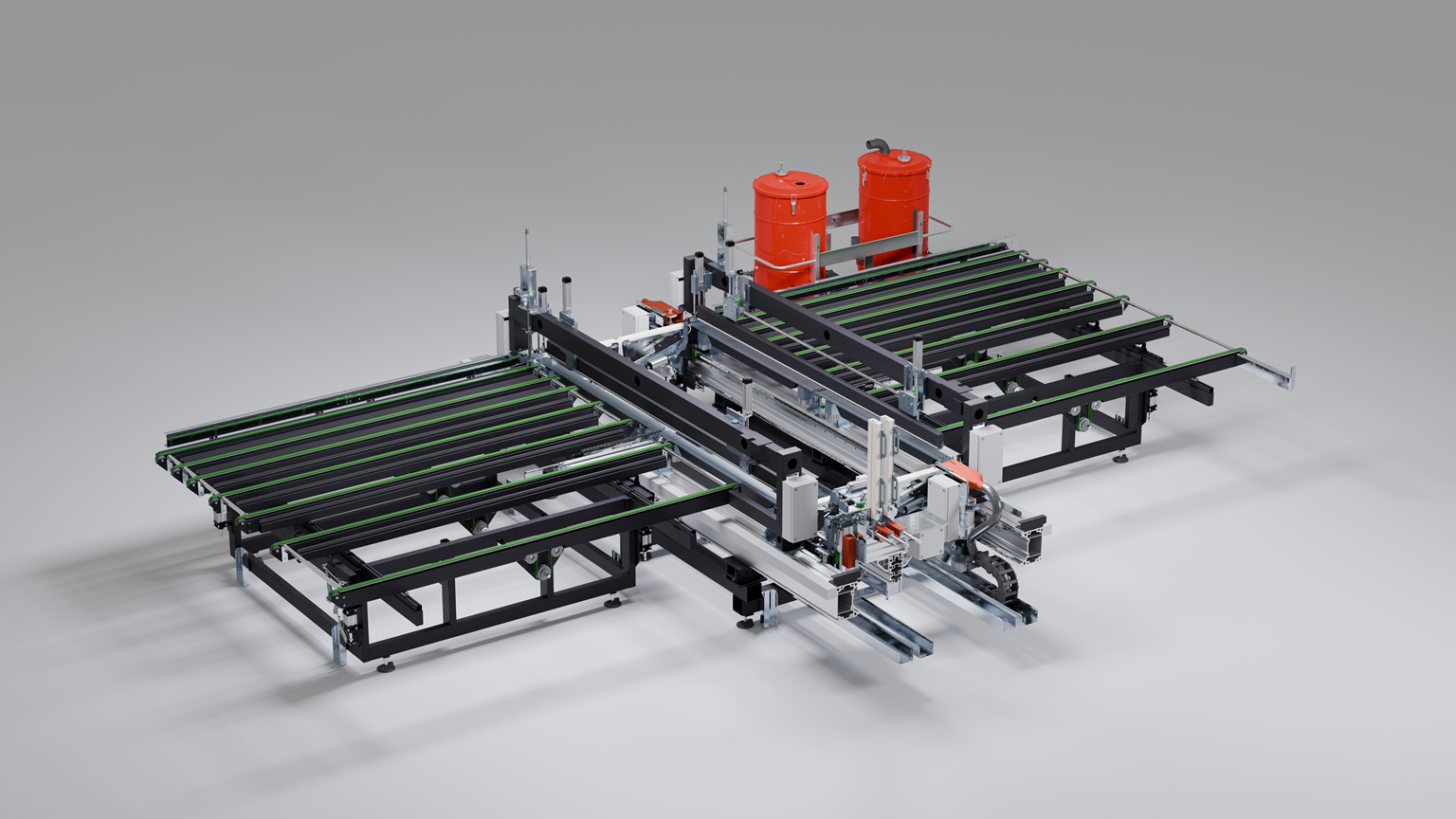

Designed to optimise the assembly of PVC shutters and blinds, BM AS CNC is the multifunctional bench that precisely automates the drilling and assembly of hinges.

With a sturdy electro-welded steel structure and scratch-resistant, low-friction work surfaces, it ensures smooth operation of the fittings and operational comfort.

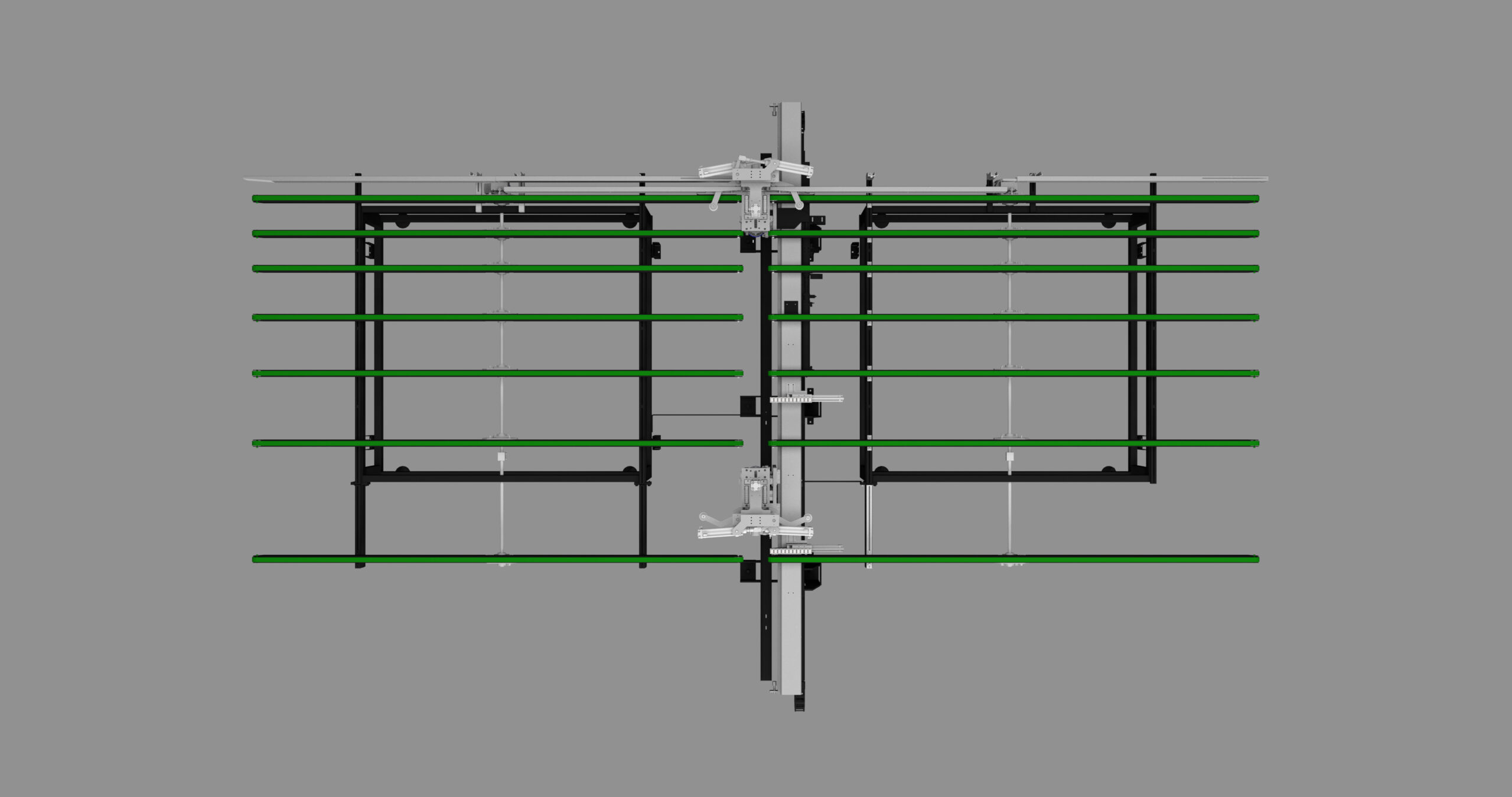

Thanks to the 2-axis controlled vertical electro-spindle, BM AS CNC ensures perfect drilling up to 1,200 x 2,400 mm, reducing time, errors, and manual effort.

5 Reasons to Choose BM AS CNC

- Modular and robust structure. Made from electro-welded steel, it provides stability and long-lasting durability even in intensive production environments.

- Versatility in Processing. Suitable for all types of profiles, it allows for drilling and screwing hinges onto panels ranging from 400×400 mm to 1,200×2,400 mm.

- Simplified Programming. Automatically receives data from the management system or via barcode; alternatively, it can be manually programmed from the panel.

- Fast and Repeatable Cycles. The CNC spindle ensures precision and repeatability in drilling, eliminating manual errors.

- Easy maintenance, reduced costs. Affordable and easily replaceable consumables: guaranteed operation at all times, with no machine downtime.

Product Details

BM AS CNC carries out all the necessary operations for preparing PVC shading systems: from the precise drilling of hinge seats to controlled screwing. The panel is loaded using pneumatic locks on fixed references, ensuring consistent positioning and uniform results.

Sizes

Length: 4,200 mm

Width: 2,200 mm

Height: 1,900 mm

Weight: 800 kg

Performance

Operation: assisted manual

Operators required: 1

POWER SUPPLY and consumption

Installed power: 2.7 kW

Voltage: 400 V

Operating pressure: 7 bar

Air consumption per cycle: 300 Nl/min

Workable profiles

Minimum dimensions: 400 x 400 mm

Maximum dimensions: 1,200 x 2,400 mm

Supported features and processes

Available services:

- Hinge drilling

- Hinge installation

Optional features and customizable settings

To further enhance ergonomics and efficiency, BM AS CNC can be equipped with:

- Tilting assembly table: makes it easier for the operator to position and handle the panels.

- Suspended Pneumatic Screwdriver: a suspended solution that enhances precision and reduces fatigue during the tightening phase.

Technology and automation

BM AS CNC incorporates a simple yet effective automation logic: it can be controlled via management software or barcode, and can also be operated manually through an operator panel. The two controlled axes of the spindle ensure fast and precise positioning. The structure is designed for future integrations into Industry 4.0 workflows, ensuring scalability and compatibility with advanced digital systems.

Request a dedicated consultation

Do you want to find out if BM AS CNC is the right solution for your production process? Contact our team to receive a detailed brochure or to schedule a demo.