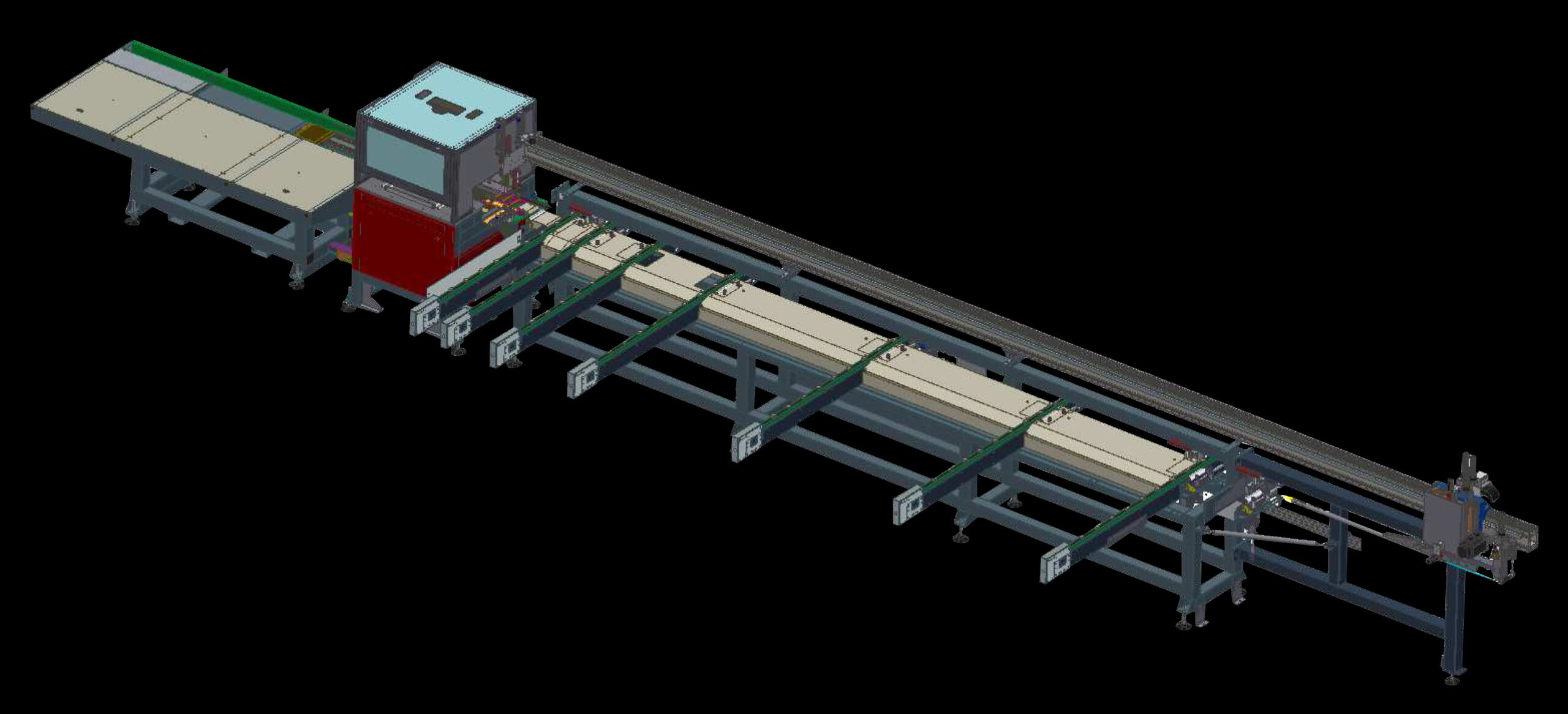

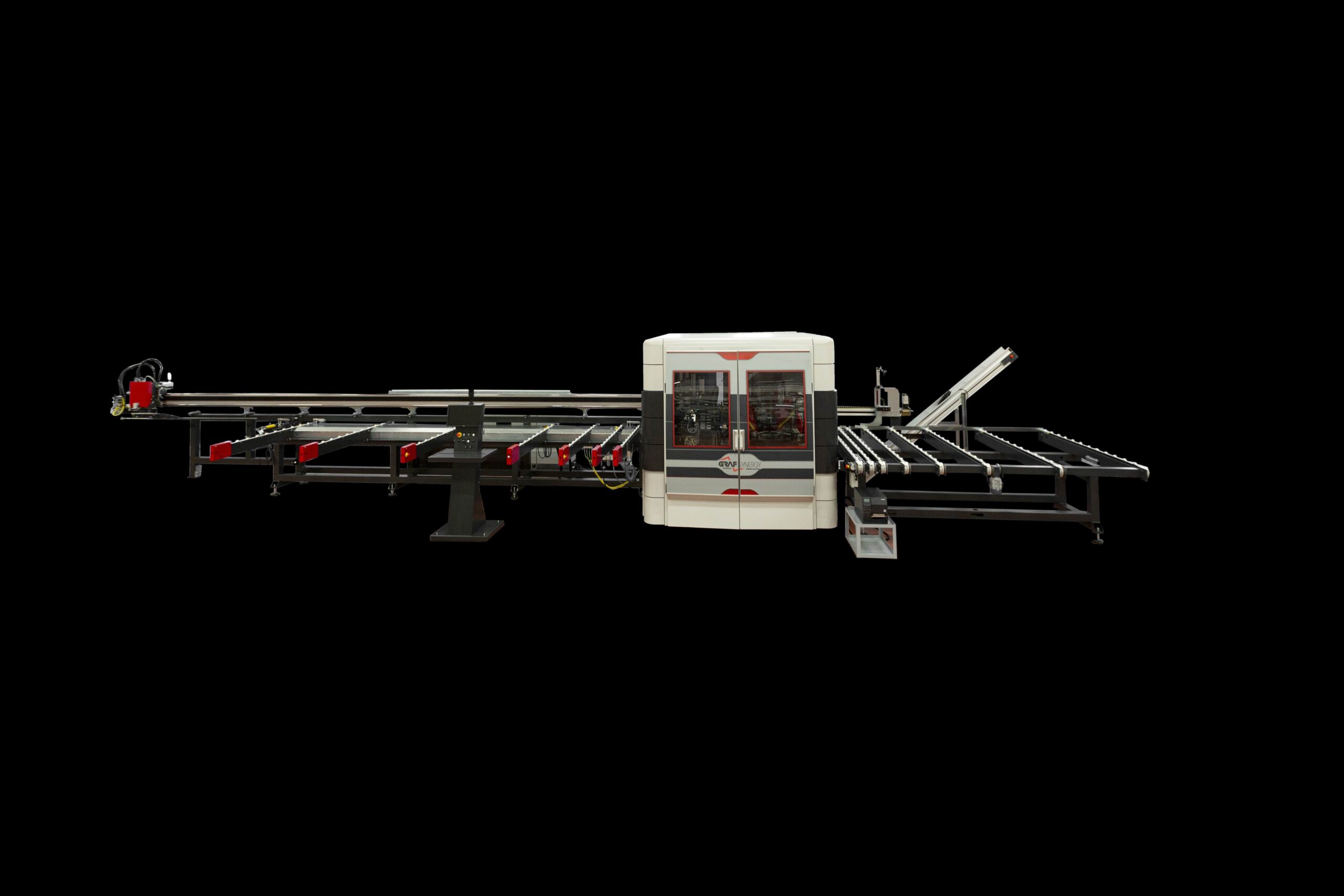

CUT 500 ALU

CNC cutting center for aluminum profiles

High-performance compact automatic cutting center

Perfect if:

- You need to automate the cutting of aluminum profiles to increase production speed.

- Small or variable batches make it difficult to optimise cutting lists.

- The profiles sometimes arrive warped or with geometric defects.

- You have limited space in the department and need a compact solution.

- Do you want to reduce operator intervention and save on labour costs?

Request the technical brochure now or speak with an expert.

High-performance compact automatic cutting center

CUT 500 ALU is a CNC cutting centre with 1 or 2 controlled axes, designed to fully automate the cutting process for aluminium profiles, even those that are not perfectly straight. From feeding to trimming and unloading, each stage is managed autonomously, ensuring precision, speed, and zero manual intervention.

Thanks to its compact design, high operational speed, and versatile configuration, it is the ideal solution for those looking to boost productivity while reducing waste and streamlining the production cycle.

5 Reasons to Choose the CUT 500 ALU

- Consistent Precision Over Time. Automatic alignment system that compensates for non-linear profiles, ensuring impeccable cutting quality under all conditions.

- Advanced Bar Optimization. The GRAF Synergy software helps minimize waste and improve raw material yield.

- Comprehensive and User-Friendly Control. Intuitive interface with simple menus, suitable for non-specialised operators.

- Maximum Integration. Designed for connection to one or two ASG-E screw feeding systems and compatible with digital management systems.

- High Reusability Value. The Fly Optimizer system automatically measures bar remnants, allowing them to be reintegrated into new cutting lists.

Product Details

CUT 500 ALU brings together all the processing stages required for cutting aluminium profiles in a single centre: from the automatic loading of bars to the unloading of finished pieces. The Ø500 mm blade, with its upward movement, ensures precision and cleanliness even on large sections.

Sizes

Length: 12,000 mm

Width: 2,200 mm

Height: 1,600 mm

Weight: 2.850 kg

POWER SUPPLY and Consumption

Installed power: 7 kW

Power Supply: 400 V

Air consumption per cycle: 100 Nl/min

Minimum operating pressure: 7 bar

Performance

Productivity: up to 300 windows/8h (varies based on profile)

Operators Needed: 1

workable profiles

Length: 500 / 6,500 mm

Width: 40 / 130 mm

Height: 40 / 135 mm

Supported features and processes

Main Processes:

- 90°, -45°, +45° cuts

- Automatic profile extraction

- Possibility of mechanical stops for fixed-size cuts

Optional available

To meet specific production needs, the CUT 500 ALU is available with a variety of optional features.

- Blade Ø550 mm for cutting profiles up to 180 mm

- Profile loading system from 400 to 700 mm

- Additional pressure kits

- Brushless blade rotation for intermediate cuts (-45°/+45°)

- Fly Optimizer for automatic bar residue optimization

- Sensors for detecting incorrect height/width of profiles

- Chip conveyor (1200/2000 mm), double bag dust collector

- Extension for discharge plan, horizontal clamps for large sections (up to 230 mm)

- Manual labeler, ASG-E connection, setup for PVC

Technology and Automation

Equipped with the latest control systems, the CUT 500 ALU uses a brushless motor for the pusher and integrates smart operating logic with sensors to prevent loading errors. The interface is designed to be user-friendly for any operator, allowing for complete management of the machine cycle with just a few commands. The machine is ready for Industry 4.0, making it compatible with ERP or MES systems for remote monitoring and production optimization.

Contact us to find out if the CUT 500 ALU is the right solution for your production.