EDU

Efficient Drilling Unit: CNC Station for Drilling Fastening Holes in PVC Profiles

Automatic drilling, zero downtime

Perfect if:

- Automatically perform the fastening drilling directly on the line.

- Reduce cycle times without sacrificing accuracy.

- Working with PVC profiles that already have reinforcement included.

- Automate the drilling of the cross members as well.

- Eliminate manual intervention with complete CNC logic.

- Integrate drilling into a cutting and machining line.

Request the technical brochure now or speak with an expert.

Automatic drilling, zero downtime

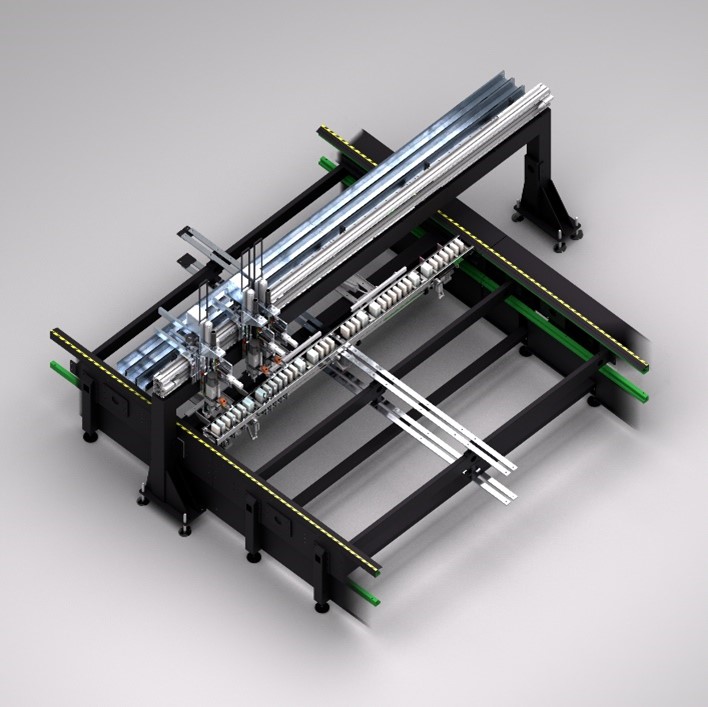

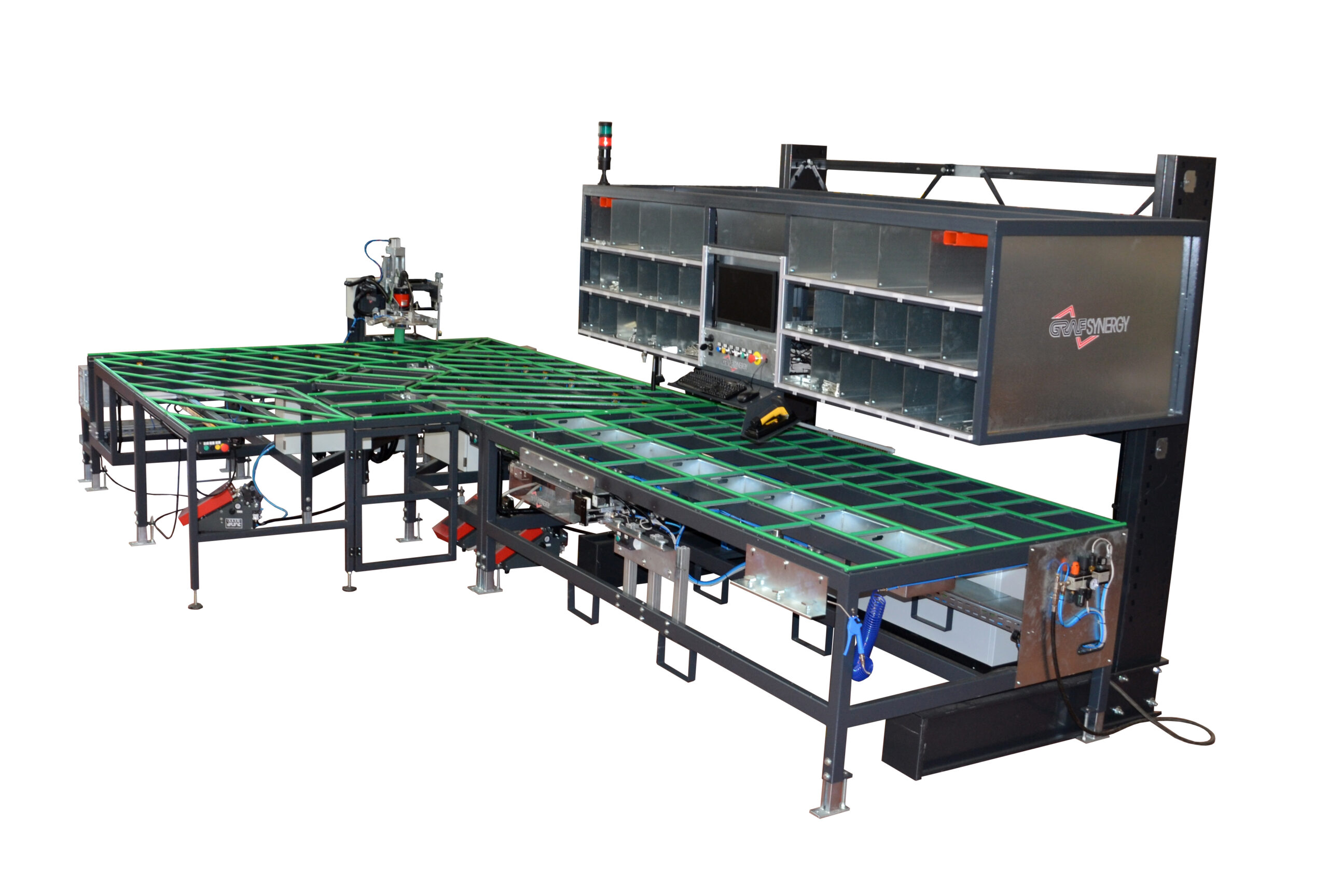

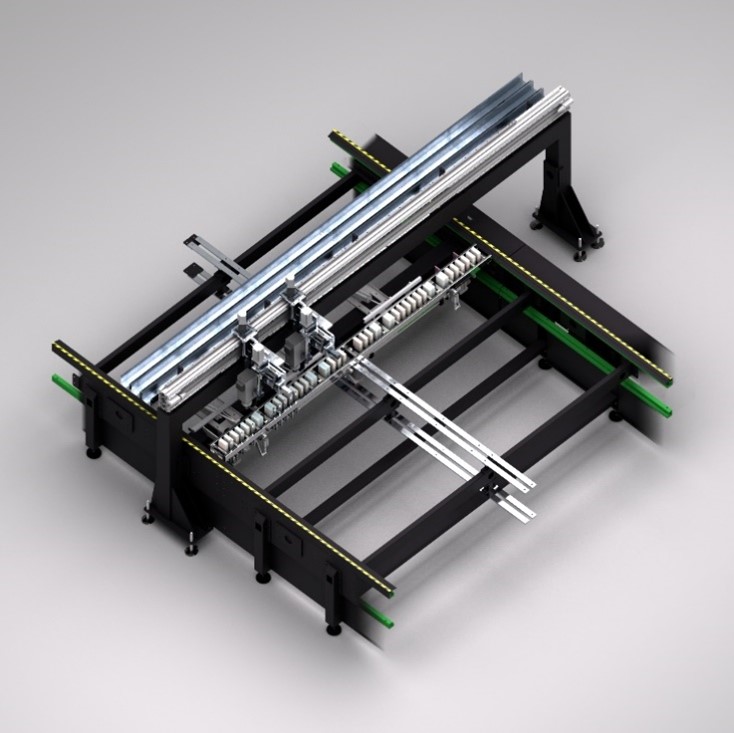

EDU is the CNC drilling station developed by Graf Synergy for the automatic and precise execution of perimeter drilling for fastening on already reinforced PVC profiles. Directly integrable onto the dynamic table, it allows for drilling to be carried out during the production flow without any interruptions, reducing cycle times and improving the overall quality of the processing.

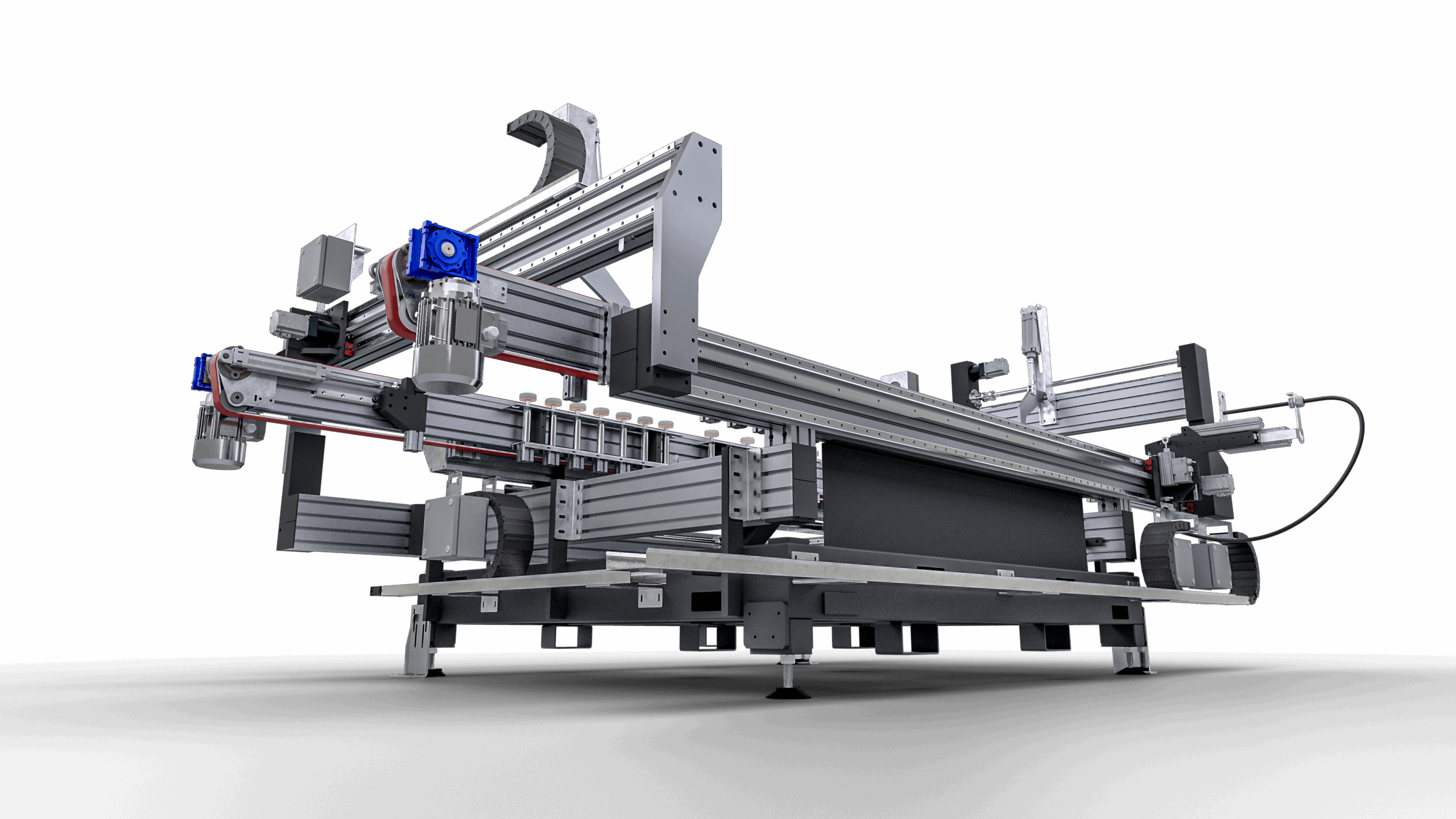

With a load-bearing bridge that accommodates up to 3 vertical drilling units, the system stands out for its flexibility, precision, and advanced automation, making it perfect for high-productivity lines and factories geared towards Industry 4.0.

5 reasons to choose EDU

- Zero Time Speed. Drilling occurs in line, without interrupting the production flow on the dynamic table.

- Parametric Precision. Each unit monitors depth, position, and feed rate for perfect drilling.

- Maximum Automation. The system operates entirely autonomously: no operator required.

- Operational Versatility. In addition to perimeter drilling, it is also possible to drill the cross members.

- Advanced Integrated Software. Complete CNC management with coordinate control on the X and Y axes for maximum programming flexibility.

Product Details

EDU is the CNC drilling station developed by Graf Synergy for the automatic and precise execution of perimeter drilling for fastening on already reinforced PVC profiles. Directly integrable onto the dynamic table, it allows for drilling to be carried out during the production flow without any interruptions, reducing cycle times and improving the overall quality of the processing.

Machine dimensions

Length: 4,500 mm

Width: 1,800 mm

Height: 2,700 mm

Weight: 2.500 kg

POWER SUPPLY and Consumption

Installed power: 9 kW

Power Supply: 400 V

Air consumption: 200 NI/min

Operating pressure: 7 bar

Operational Features

- Number of drilling units: up to 3 (vertical)

- X-axis movement: automatic longitudinal

- Y-axis movement: automatic cross positioning

- Operating mode: CNC

- Operators required: 0

Workable profile sizes

- Length: 350 – 4,000 mm

- Width: 40 – 130 mm

- Height: 40 – 120 mm

Types of Work

- Automatic perimeter fastening drilling

- Possibility of drilling for cross fastening

Integration

- Compatible with Graf Synergy dynamic table.

- Ideal for CNC Cutting and Machining Centers

TECHNOLOGY AND AUTOMATION

The EDU represents a technological leap in perimeter drilling management. The entire process is controlled by advanced software that manages the trajectories and parameters of each individual drill. Thanks to direct integration with the dynamic table and simultaneous control of the X and Y axes, maximum productivity can be achieved with minimal tolerances, even on already reinforced profiles.

Contact us to find out if EDU is the right solution for your production.