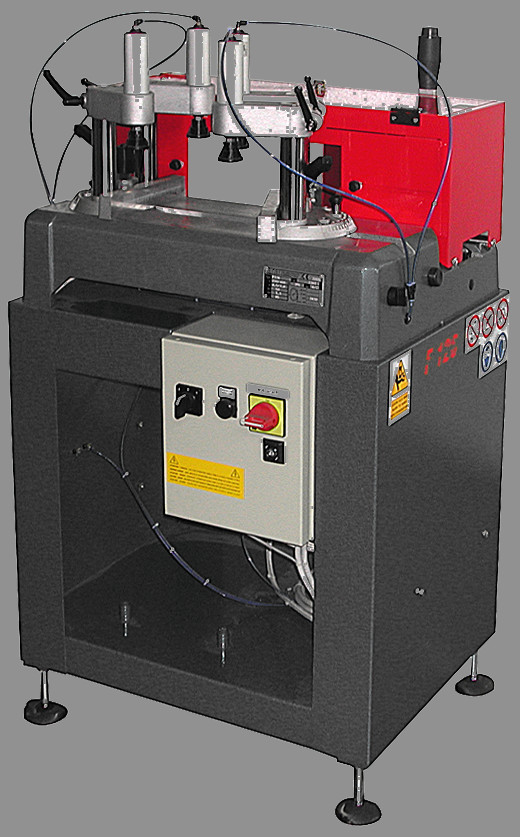

F 126 ALU

Variable angle manual header for aluminum

Flexibility and precision in aluminium profile milling

Perfect if:

- Cross beams and upright aluminum profiles with angular versatility up to ±45°

- You have limited space in your workshop and are looking for a compact and stable machine.

- You work with complex profiles and need a secure locking system.

- Do you want to reduce tool change times with a quick pneumatic system?

- Do you need a ready solution for occasional work, including on PVC?

Request the technical brochure now or speak with an expert.

Flexibility and precision in aluminium profile milling

The F 126 ALU is a compact and reliable end milling machine designed for processing aluminium crosspieces and uprights, ideal for window manufacturers seeking maximum precision at an affordable cost. Available in both manual and hydropneumatic feed versions, it allows for the end milling of profiles at variable angles, easily adapting to different production needs.

Thanks to the vertical and horizontal pneumatic vises and the angular adjustment device (+45°/-45°), it ensures stable clamping of the workpiece and precise machining, even in tight spaces. The integrated tool cooling system guarantees consistent performance, reducing wear on the cutters.

Compact, sturdy, and ready to use, it is the perfect solution for those looking for a functional and modular machine with additional options to boost productivity.

5 reasons to choose the F 126 ALU

- Quick Tool Change. A dedicated pneumatic device for the fast replacement of milling heads: less downtime, more efficiency.

- Extremely easy to use. Intuitive interface and direct commands, perfect for operators with little experience.

- Integrated suction. Prepared for smoke and chip extraction with a Ø100 mm connection: a clean and safe working environment.

- Perfect Profile Clamping. Pneumatic horizontal and vertical clamps for a stable grip on any geometry.

- Sturdy and compact structure. 27 mm diameter tool holder on a reinforced machine body: precise machining even with wide profiles.

Product Details

Designed for the milling of cross members and uprights in aluminium, the F 126 ALU features an adjustable bevel angle that makes it flexible and precise, even for custom productions. The single spindle action combined with a full pneumatic locking system ensures reliable machining, even on complex or large profiles.

Sizes

Length: 1,050 mm

Width: 850 mm

Height: 1,600 mm

Weight: 130 kg

POWER SUPPLY and Consumption

Installed power: 1.1 kW

Power Supply: 400 V three-phase

Air consumption per cycle: 15 Nl/min per cycle

Minimum operating pressure: 7 bar

Performance

Operations: 1 operator

Production: Bars processed manually (varying based on the operator’s experience)

Workable profiles

Maximum profile height: 110 mm

Maximum profile width: 280 mm

Supported features and processes

Main Processes:

- Linear and inclined header (±45°)

- Milling of aluminum profiles

- Occasional processing of PVC (with optional cooling)

Optional available

The F 126 ALU can be configured to meet specific production needs. It is possible to integrate:

- Hydraulic-Pneumatic Advancement of Milling Head for Automatic Cycles

- 4-Position Mechanical Stop for precise and repetitive cuts

- Tool cooling system for milling PVC profiles

These options extend the machine’s usability, transforming it into a highly flexible and customizable resource.

TECHNOLOGY AND AUTOMATION

Despite being a manual machine, the F 126 ALU incorporates highly reliable components and is designed for semi-automatic accessories. The optional oleopneumatic control allows for automated feeding, reducing the operator’s effort and ensuring consistent results. The machine’s capability for chip extraction and compatibility with suction systems make it ready for efficient integration even in more structured production lines.

Contact us to find out if F 126 ALU is the right solution for your production.