F 130

Manual double-head pantograph for quick milling and drilling.

Maximum simplicity for precise work on PVC and aluminium profiles

Perfect if…

- Do you want to create notches and handle holes easily and quickly?

- You work in a craft workshop or on a semi-automatic production line.

- You need a compact yet functional car.

- Are you looking for a ready-to-use solution without CNC complexities?

- Do you want to reduce manual processing times with dedicated jigs and fixtures?

- You need operational flexibility with Ø10 and Ø12 mm end mills.

Request the technical brochure now or speak with an expert.

Maximum simplicity for precise processing of PVC and aluminium profiles

The F 130 pantograph is the ideal solution for workshops looking for operational speed and manual precision in the machining of recesses and handle holes.

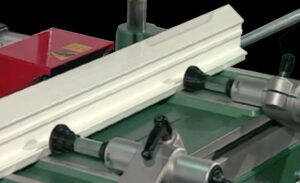

With two dedicated heads – one for vertical milling with a template and one for horizontal drilling – it allows for quick execution of all essential operations for preparing PVC or aluminium frames.

Compact and intuitive, it is designed to reduce setup time, increase efficiency, and ensure consistent results.

The fully manual operation makes it perfect for those who want to maintain direct control over the process without compromising on quality and versatility.

5 Reasons to Choose F 130

- Two independent heads for simultaneous operations. Vertical milling and horizontal drilling in a single station, without the need for repositioning.

- Template-assisted milling for precise results. Copying system with adjustable 3-diameter probes, ideal for standard cutouts on PVC and aluminium profiles.

- Integrated 3-Point Handle Drilling. Horizontal module with multiple tips for making precise holes in a single pass.

- Secure Workpiece Clamping. Vertical and horizontal pneumatic vise system for quick and stable clamping.

- Compact size, high efficiency. Just 1,050 mm in length for a lightweight machine (150 kg), easy to install even in tight spaces.

Product Details

The F 130 pantograph allows for a full range of manual milling and drilling operations, ensuring reliable and repeatable results.

Sizes

Length: 1,050 mm

Width: 850 mm

Height: 1,600 mm

Weight: 150 kg

Performance

Operation: Manual

Number of operators: 1

Travel (X / Y / Z): 490 / 140 / 140 mm

POWER SUPPLY and Consumption

Installed power: 1.1 kW

Power Supply: 400 V

Minimum operating pressure: 7 bar

Air consumption per cycle: 5 Nl/min

Supported features and processes

Main processes:

- Vertical notching using a template

- Longitudinal and transverse milling

- Locking holes and accessories

- Handle holes (3 simultaneous points)

The copying unit is equipped with adjustable manual gauges that can be set to three different diameters, compatible with cutters of Ø10 and Ø12 mm, easily adapting to various profile configurations.

Optional features and available configurations

To enhance the versatility of the F 130 pantograph, it can be equipped with a range of optional accessories:

- Hydraulic-pneumatic advancement for drilling head

- Manual centring device (up to 2,300 mm)

- Pneumatic keypads

- Stop plate with dimensions 150×150 mm

- Star stop with 4 positions

- 1,500 mm roller conveyors and side supports

- Pneumatic refrigeration system

These options allow for customization of the machine according to specific production needs, enhancing both ergonomics and productivity.

Technology and Control

The F 130 is a fully manual pantograph designed for those who prefer simplicity and direct control over the process. While it doesn’t feature CNC technology, it incorporates practical solutions to enhance precision and safety, such as:

- Pneumatic locks

- Adjustable keypads

- Automatic tool refrigeration

Its robust and functional design ensures long-term operational reliability, even with intensive use.

Request the brochure or a personalised consultation now.

Want to know if the F 130 pantograph is the right choice for your department? Download the PDF datasheet or contact our experts now for a tailored consultation.