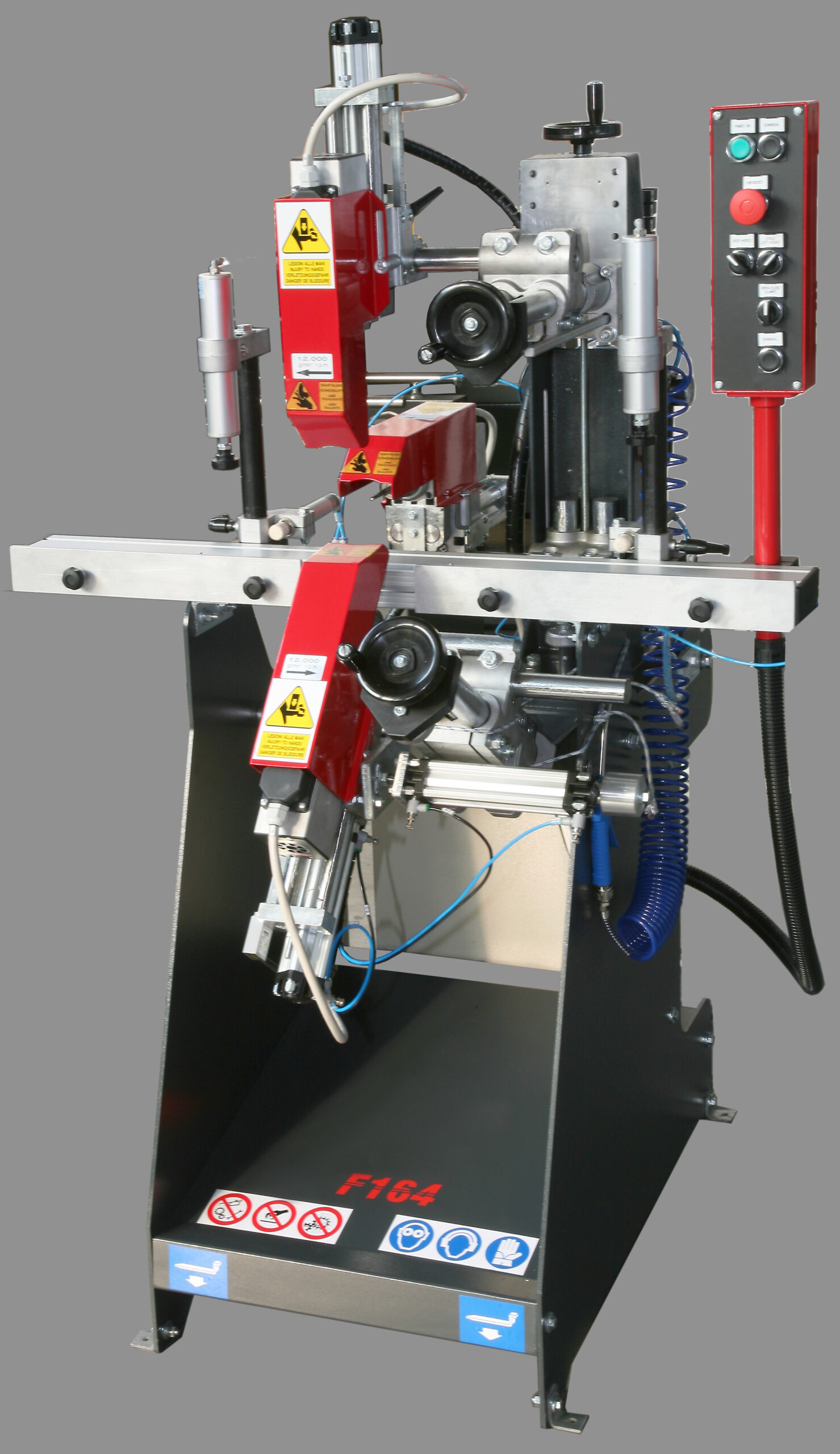

F 131

Manual milling machine for PVC profiles and pre-welded frames

Maximum precision in horizontal and vertical machining, even on pre-assembled panels

Perfect if:

- You have pre-welded parts and need to create slots and holes with a single machine.

- Do you want to reduce downtime with mechanical presetting of measurements?

- Are you looking for a robust, precise, and space-saving solution for manual tasks?

- You need an affordable yet professional milling machine for small to medium production runs.

- Are you looking for a versatile car that can be expanded with various options according to your needs?

- You have only one operator in the workshop and you want to optimise their efficiency.

Request the technical brochure now or speak with an expert.

Maximum precision in horizontal and vertical machining, even on pre-assembled panels

The F 131 is a compact and sturdy manual milling machine, designed to quickly and easily perform milling and drilling operations on PVC profiles, even those that have already been welded.

Thanks to its dual operating head – a vertical one for the Cremonese latch and a horizontal three-point head for handle and lock holes – it offers great versatility during production.

The painted steel structure with leveling feet ensures stability and precision even in the most intensive production environments. It’s ideal for craftsmen and manufacturers looking for reliable machinery that is easy to use and ready to operate immediately, without the need for CNC programming.

5 Reasons to Choose F 131

- Ready to use, no learning curve. No software to set up: the F 131 is ready to go with simple and intuitive controls.

- Dual operational head, double efficiency. Vertical milling and horizontal drilling in a single setup: reduce movement and enhance productivity.

- Consistent precision on every profile. The mechanical preset and adjustable side rods ensure repeatability and quick setup.

- Compact yet sturdy. The steel structure ensures durability, with compact dimensions that are perfect for tight spaces.

- Quick Pneumatic Clamping. Pneumatic clamps ensure a secure hold of the workpiece, even on delicate profiles.

Product Details

Designed to simplify and speed up milling and drilling operations, the F 131 allows for the most common processes in the production of PVC fixtures.

Thanks to the pneumatic locking system and ergonomic design, the operator works safely and with maximum control.

Sizes

Length: 1,200 mm

Width: 1,000 mm

Height: 1,600 mm

Weight: 235 kg

Performance

Operations: Manual

Operators required: 1

POWER SUPPLY and Consumption

Installed power: 1.6 kW

Voltage: 400 V

Minimum pressure: 7 bar

Air Consumption: 15 Nl/min

milling capabilities

X-axis travel: 240 mm

Y-axis travel: 140 mm

Z-axis travel: 140 mm

Supported features and processes

The two integrated heads allow for:

- Drilling for locks on PVC profiles

- Handle hole creation

- Vertical milling of the Cremonese slot

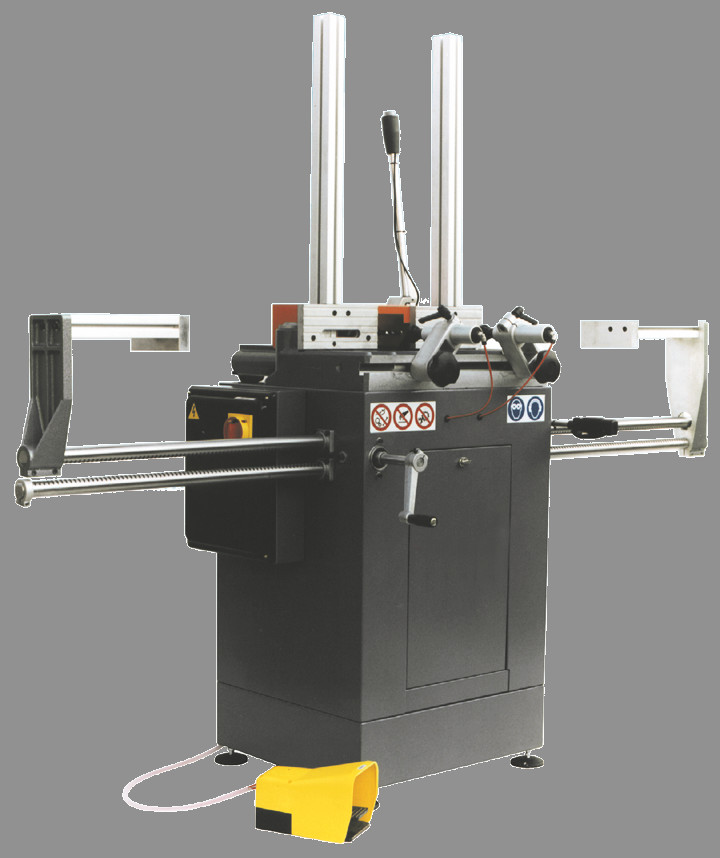

Optional and configurations

The F 131 can be configured with various optional accessories to meet specific processing or production needs:

- Hydraulic-pneumatic advancement for the drilling head

- Profile alignment centering group

- Stop block with a 150×150 mm plate

- Star stop with 4 positions

- Side profile supports (Left + Right) measuring 1,500 mm

- Additional stop blocks

Automated version available:

Model F 131 S with automatic movement using oleo-pneumatic pistons.

Request a detailed technical brochure now or contact our experts for personalised advice.