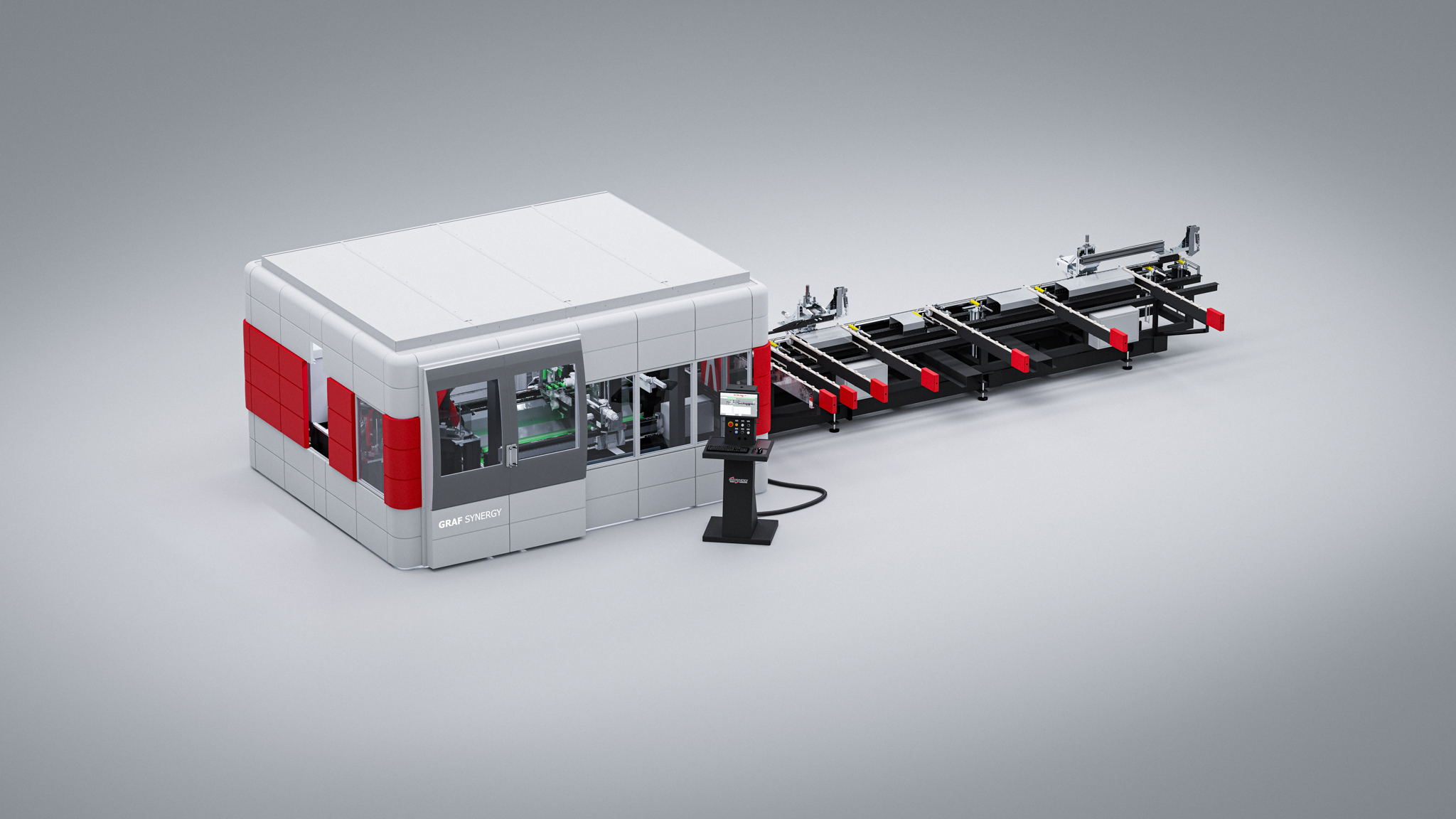

FAB CUT 3B

Three-Blade Cutting and Working Center

8-axis CNC cutting and machining centre designed for window manufacturers seeking high productivity levels (up to 220 windows/8h per sash*).

Perfect for:

- Manufacturing entities that need to manage large volumes while maintaining high-quality standards and optimising production schedules to the fullest.

- Ideal for high-efficiency setups in PVC cutting and window fabrication departments.

Request the technical brochure now or speak with an expert.

8-axis CNC cutting and machining centre designed for window manufacturers requiring high productivity levels (up to 220 windows/8h per sash*).

An advanced expression of mechanical and digital technology, it is designed to perform all machining and cutting operations with the highest precision and speed, while ensuring reliability and consistent performance over time.

5 Reasons to Choose the FAB CUT 3B

- Ultra-fast execution speed: a work module capable of accommodating up to 12 High Speed spindles (6 standard) and a cutting module with 3 independent and synchronized blades.

- Extremely adaptable to profiles with sections of specific dimensions.

- Optimize production lists: use fewer bars with GRAF Synergy software.

- Maximum precision: automatic profile alignment system (straightens bars that are not perfectly straight) and CNC profile clamp with position reading via centesimal magnetic strip.

- User-Friendly Technology: intuitive software for simple and effective workflow management.

Product Details

Sizes

Length: 15,250 mm

Width: 3,400 mm

Height: 2,800 mm

Weight: 3.800 kg

POWER SUPPLY and Consumption

Installed power: 20 kW

Power Supply: 400 V

Air consumption per cycle: 150 Nl/min

Minimum operating pressure: 7 bar

Required Operators: 1

Performance

Up to 220 single-sash windows per 8-hour shift* (* Depending on the processing and type of profile used)

Automatically uploadable profile sizes

Length: 500 / 6,500 mm

Width: 40 / 130 mm

Height: 40 / 130 mm

Loading Form

- Loading dock with a maximum capacity of 8 bars.

- Bar loading system using belts

- CNC profile clamp with 2 controlled axes, driven by a linear motor on prismatic guides with position reading on a hundredth magnetic band.

Work Module

- 6 high-speed chucks (expandable up to 12)

- Processes: drain holes for condensate, handle holes, cylinder hole, hinge holes, ventilation holes, lock cutout, marking for fittings, various machining on PVC profiles.

Cutting Module

3 blades Ø 550 mm for ultra-high precision cutting, even on profiles with seals.

Horizontal movement

Cutting Angles: -45° / 90° / +45°

Discharge Form

Automatic extractor for cut profiles on controlled axis.

Belt conveyor unloading table with safety photocell

Maximum capacity: 12 pieces

Optional available

- Configuration with 6 additional spindles

- STATS: software for production data analysis (daily, weekly, monthly, and annual monitoring)

- Fly Optimizer: automatic measurement of bar remnants for subsequent optimization

- Recover Option: reinsert incorrect pieces into a new cutting list

- Customized solutions for profiles with unique shapes (subject to technical analysis)

- Custom soundproof booth

- Vacuum cleaner with 2 bags

- Chip conveyor (available in 1,200 or 2,000 mm versions)

- Motorized discharge table with opposite side outlet

- Preparation for connection to 1 or 2 ASG-E Screw Feeding Centers

- Manual and automatic labeler

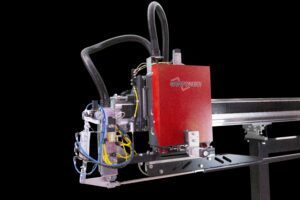

- Single or double laser for profile marking

- Tool breakage sensors

Available variants

- Setup for cutting and working with aluminum profiles

Contact us now to find out how Fab Cut 3B can revolutionise your department’s productivity!