FAB CUT 3B ALU

High-Speed Cutting and Machining Centre for Aluminium Profiles

Extreme productivity, absolute precision: the ideal partner for those looking to cut and work with aluminium profiles without compromise.

Perfect if:

- Do you need to drastically increase your daily productivity?

- Do you want to reduce waste by optimising cutting lists?

- We work with aluminium profiles that have complex shapes or are not perfectly straight.

- Are you looking for a car that ensures consistent precision and reliability over time?

- Do you want to reduce your operational workload with an integrated and user-friendly CNC system?

Request the technical brochure now or speak with an expert.

Extreme productivity, absolute precision: the ideal partner for those who want to cut and work with aluminium profiles without compromise.

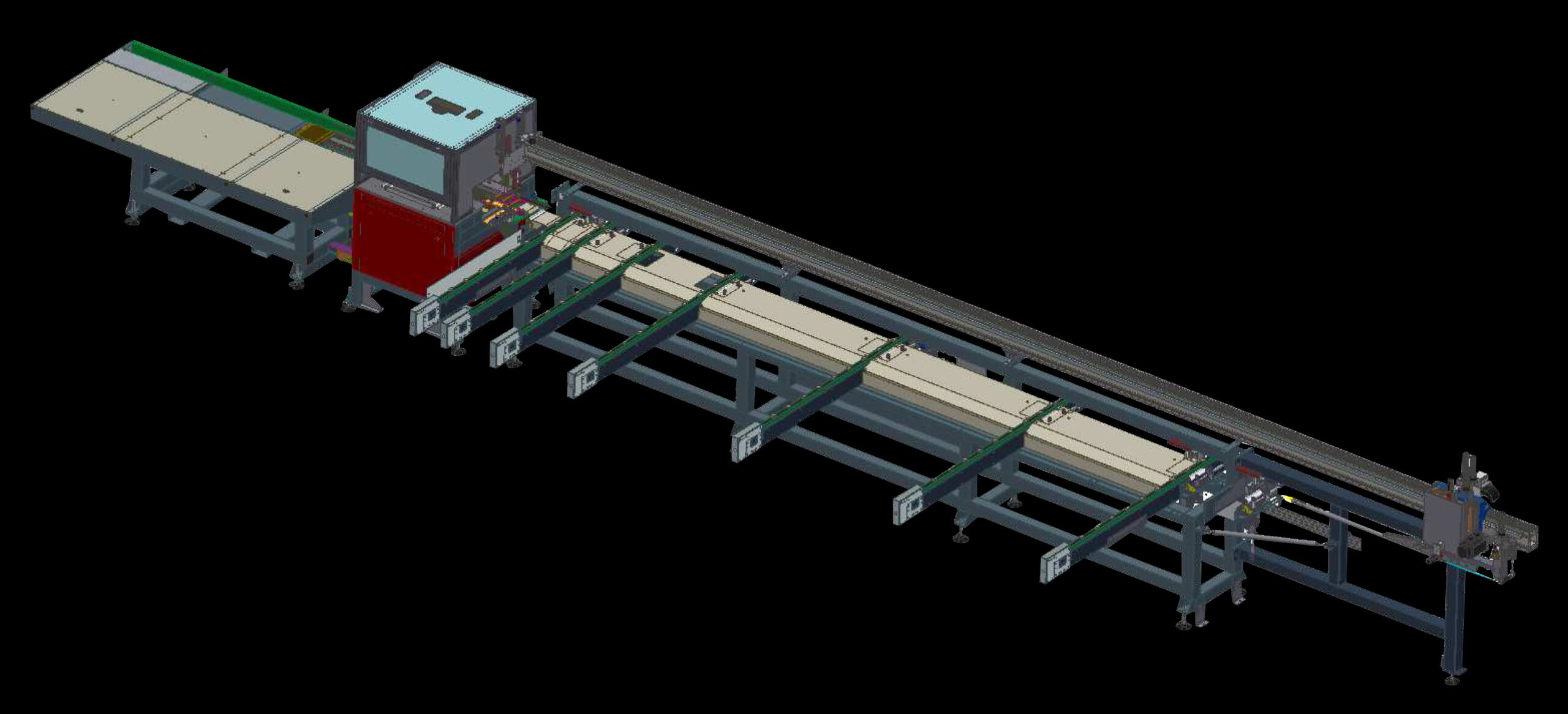

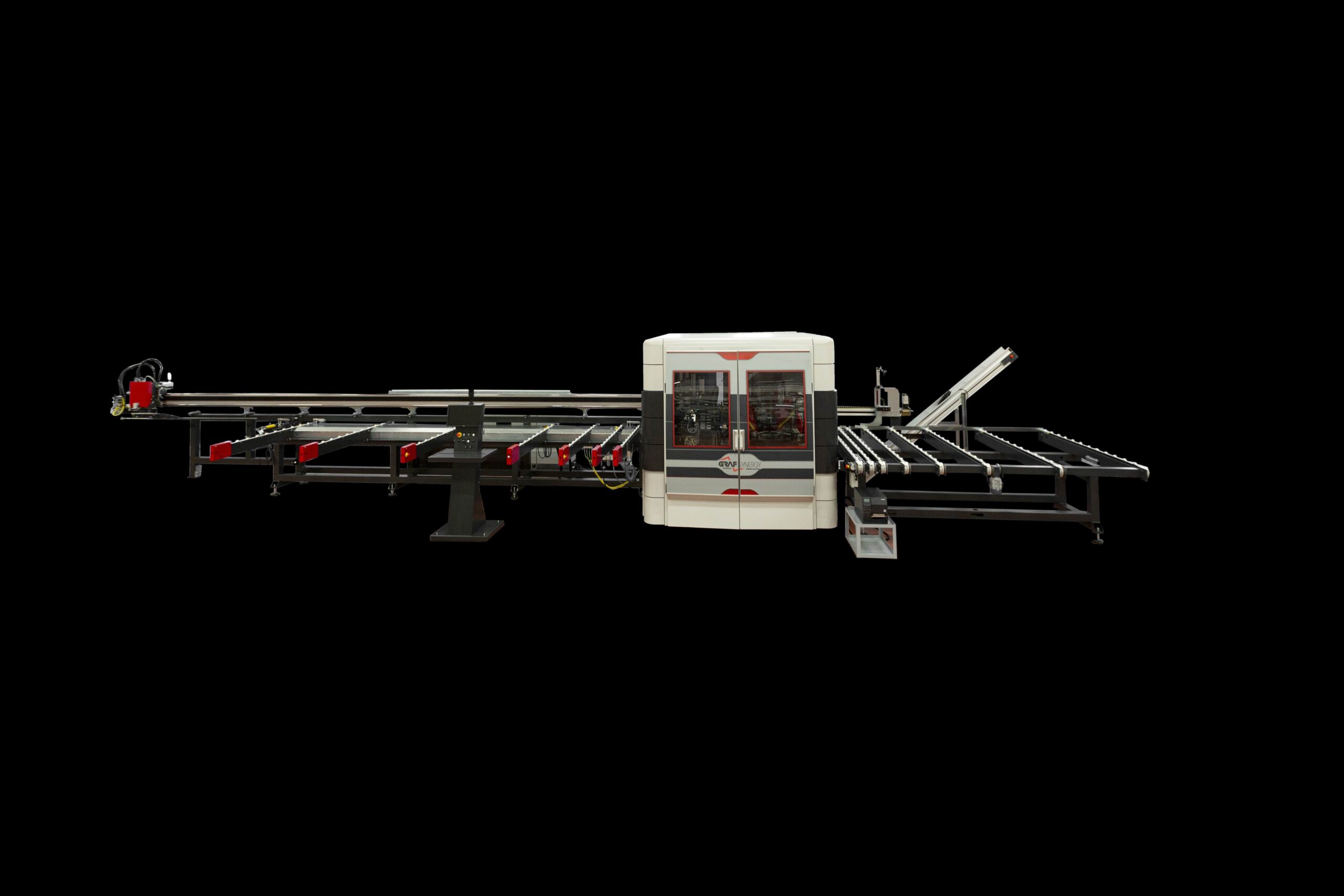

The FAB CUT 3B ALU is an 8-axis CNC cutting and machining centre, designed to meet the needs of the most demanding window manufacturers. Capable of producing up to 220 single-sash windows per shift, it combines processing speed, adaptability, and consistent quality over time.

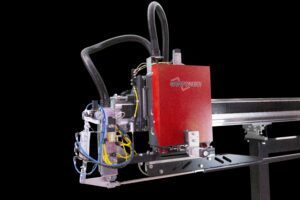

Thanks to the cutting module with 3 independent blades Ø 550 mm and the working module with up to 12 High Speed spindles, it performs high-precision machining and cutting, optimising every cycle to the fullest. It is the ideal choice for those seeking smart automation, the ability to adapt to complex profiles, and a quick and measurable return on investment.

5 Reasons to Choose the FAB CUT 3B ALU

- Maximum Operating Speed. Work module with up to 12 high-speed spindles and simultaneous cutting on 3 synchronized blades: more processing in less time.

- Adaptability to more complex profiles. The automatic alignment system also straightens bars that are not perfectly straight, ensuring flawless results.

- Smart Bar Optimization. GRAF Synergy software minimizes waste by generating optimized production lists.

- Micrometric precision guaranteed. CNC clamp with centesimal magnetic band: every cut starts from the actual position of the profile.

- Intuitive Interface. A user-friendly system for easy and quick management of work cycles, even by a single operator.

Product Details

The FAB CUT 3B ALU performs all major operations on aluminium profiles, combining speed of execution with stability of results.

Sizes

Length: 15,250 mm

Width: 3,400 mm

Height: 2,800 mm

Weight: 4.500 kg

POWER SUPPLY and Consumption

Installed power: 20 kW

Power Supply: 400 V

Air consumption per cycle: 150 Nl/min

Minimum operating pressure: 7 bar

Performance

Productivity: up to 220 pieces/8h*

Operators required: 1

(*depending on profile and tasks)

workable profiles

Length: 500 / 6,500 mm

Width: 40 / 130 mm

Height: 40 / 180 mm

Supported features and processes

Work Form:

- Condensate drain holes

- Handle holes, hinges, cylinders

- Lock picking

- Ventilation holes

- Feedback marking

- Custom processing available upon request.

Cutting Form:

- 3 blades Ø 550 mm

- Cutting angles: -45° / 90° / +45°

- Automated horizontal movement

Optional available

The FAB CUT 3B ALU can be configured with a wide range of options to perfectly meet every production requirement.

- 6 additional chucks for the work module

- STATS software for production data analysis

- Fly Optimizer for automatic waste recovery

- Recovery option for post-error rework

- Custom adaptations for special profiles

- Chip conveyor (1,200/2,000 mm)

- Industrial vacuum cleaner with 2 bags

- Custom soundproof booth

- Motorized unloading table (also on the opposite side)

- Integration with ASG-E Screw Driving Centers (1 or 2)

- Manual or automatic labeling

- Laser marking (single or double)

- Tool breakage sensors

TECHNOLOGY AND AUTOMATION

Every component of the FAB CUT 3B ALU is designed to fit into a framework of digital and flexible production. The centre uses proprietary GRAF Synergy software for optimising lists and managing processes, and is prepared for integration into Industry 4.0 environments.

- Advanced CNC system with 8-axis control

- Reading position with high-resolution magnetic band

- Automatic extractors and motorized belt tables

- Simple and multilingual operator interface

- Compatibility with monitoring and tracking systems

Contact us to find out if FAB CUT 3B ALU is the right solution for your production.