FAB CUT 3B RS

High-performance CNC cutting and machining centre for PVC profiles

High-speed cutting and processing for uncompromised productivity

Perfect if you want:

- Significantly reduce cycle times through automatic overlap of operations.

- Optimize the use of bars with intelligent cutting management software.

- Ensure maximum accuracy even with profiles that are not perfectly straight.

- Fully automate the loading, cutting, and unloading of profiles.

- Manage the entire process with a simple and intuitive software interface.

Request the technical brochure now or speak with an expert.

High-speed cutting and processing for uncompromised productivity

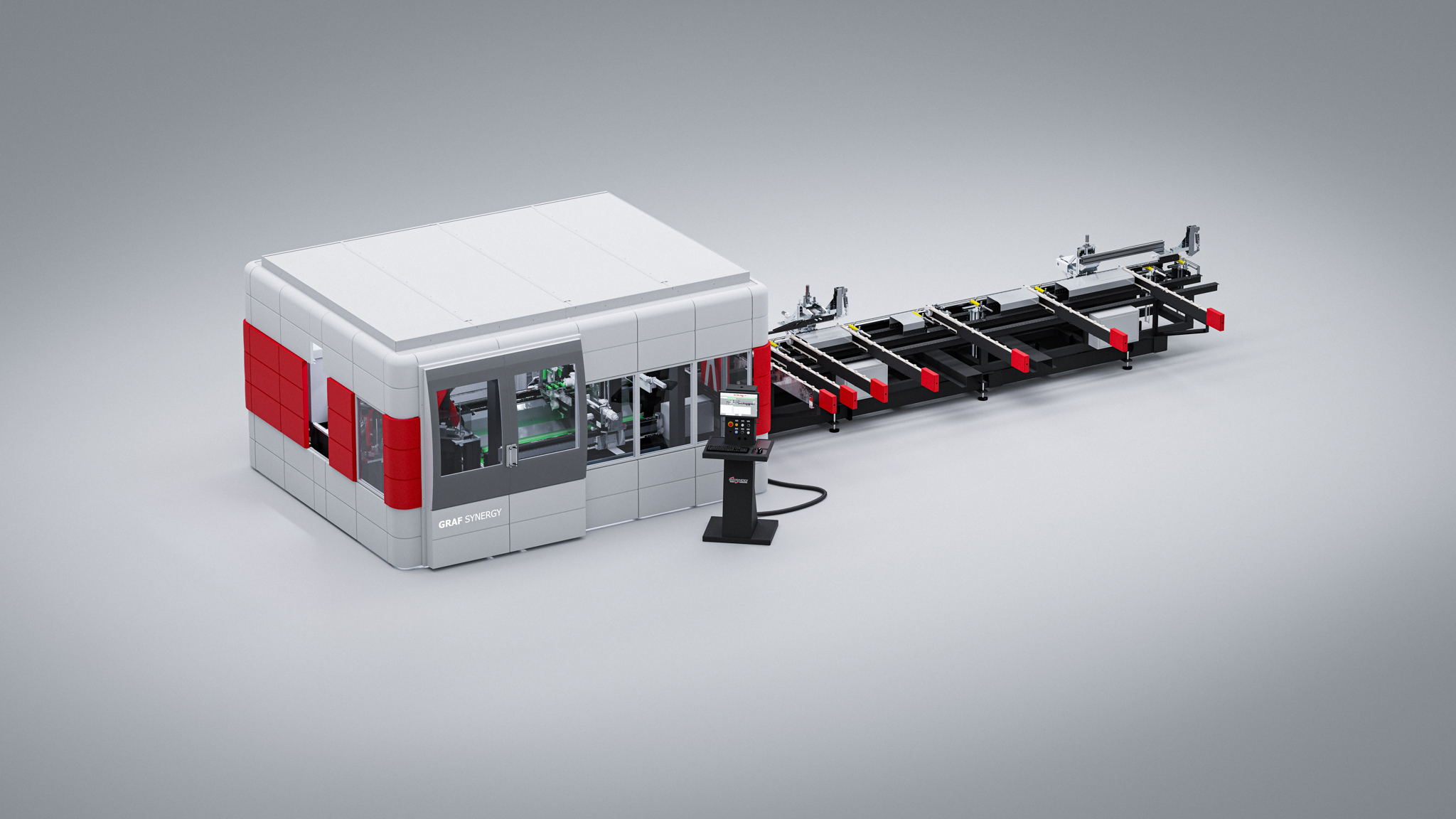

The FAB CUT 3B RS is a CNC cutting and working centre designed to meet the needs of window and door manufacturers aiming for maximum production efficiency. With its innovative configuration and the integration of smart software and state-of-the-art mechanical components, the system allows for the production of up to 500 frames per shift (8 hours)*, maintaining consistent processing quality over time.

The system consists of three main modules: an automatic loading system with a dual CNC gripper, a working module with two independent high-speed spindles, and a cutting module with three synchronized blades. Each component is optimized to eliminate downtime, maximize precision, and ensure operational continuity even with the most complex profile shapes.

*Productivity depends on the types of processes and profiles used.

5 Reasons to Choose the FAB CUT 3B RS

- Maximum Operating Speed. Overlapping work phases, dual CNC clamps, and independent spindles help eliminate downtime and increase hourly output.

- Guaranteed Precision Over Time. The automatic profile alignment system corrects any curvature, while the centesimal reading via magnetic band ensures perfect positioning.

- Extreme adaptability. It effortlessly handles profiles with non-standard sections and geometries, thanks to a flexible and configurable architecture.

- Smart Resource Optimization. The GRAF Synergy software automatically imports production lists and optimizes bar usage, reducing waste.

- User-friendly technology. A simple and intuitive interface for managing workflows, featuring easy-to-use controls and real-time visual feedback.

Product Details

The cutting module is equipped with three independent and synchronized blades of Ø 550 mm, capable of making cuts at -45° / 90° / +45° on PVC profiles, even with seals. The horizontal movement of the blades ensures speed and precision.

Sizes

Length: 16,400 mm

Width: 4,300 mm

Height: 2,600 mm

Weight: 10,000 kg

Performance

Productivity: up to 500 frames / 8h*

Required operators: 1

POWER SUPPLY and Consumption

Installed power: 34 kW

Power Supply: 400 V

Air consumption per cycle: 250 Nl/min

Minimum pressure: 7 bar

Workable profiles (automatic)

Length: 500 / 6,500 mm

Width: 40 / 130 mm

Height: 40 / 120 mm

Supported features and processes

The work module is equipped with 2 high-speed rotating spindles, positioned on independent 3-axis controlled carriages. This allows for the simultaneous execution of distinct operations, such as:

- Ventilation holes

- Other processing available upon request for PVC profiles.

- Condensate drain holes

- Handle holes, cylinder, hinge

- Lock picks

- Feedback marking

Optional features and custom configurations

The FAB CUT 3B RS is available with a wide range of options to meet every production need:

- Additional third spindle

- Option ‘Recover’: re-adding items to the recovery list

- Fly Optimizer: automatic measurement of bar remnants

- Soundproof booth and chip extraction systems

- Manual labeler or automatic applicator

- STATS software for time and productivity analysis

- Customization for special profiles (based on technical analysis)

- Prepared for integration with dynamic tables, EDU/ESU screw bridges, and RMA assembly stations.

- Chip conveyor (1,200 / 2,000 mm)

- Single or double laser for marking

Automation and advanced software

The intelligent heart of the machine is the management software developed by GRAF Synergy, designed to automatically import cutting lists, optimise cycles, and monitor performance. With a user-friendly interface, the operator can easily and accurately program and control every stage of the process.

The machine is designed for integration into Industry 4.0 systems, with capabilities for data analysis, remote assistance, and connectivity with the company’s management software.

Request the full brochure now or book a personalised demo with our technicians to discover how the FAB CUT 3B RS can revolutionise your production.