FAB CUT ALU

CNC cutting and machining centre for aluminium profiles

Maximum productivity and precision on every profile: your ally for complete automation.

Perfect if:

- You need to produce in large volumes while maintaining millimetric precision.

- Do you want to minimise human intervention and maximise automation?

- Are you looking for a flexible and compact CNC cutting and machining centre?

- Manage profiles that aren’t perfectly straight and want flawless results.

- Do you want a system set up for Industry 4.0 and connected to the management software?

Request the technical brochure now or speak with an expert.

Maximum productivity and precision on every profile: your ally for complete automation.

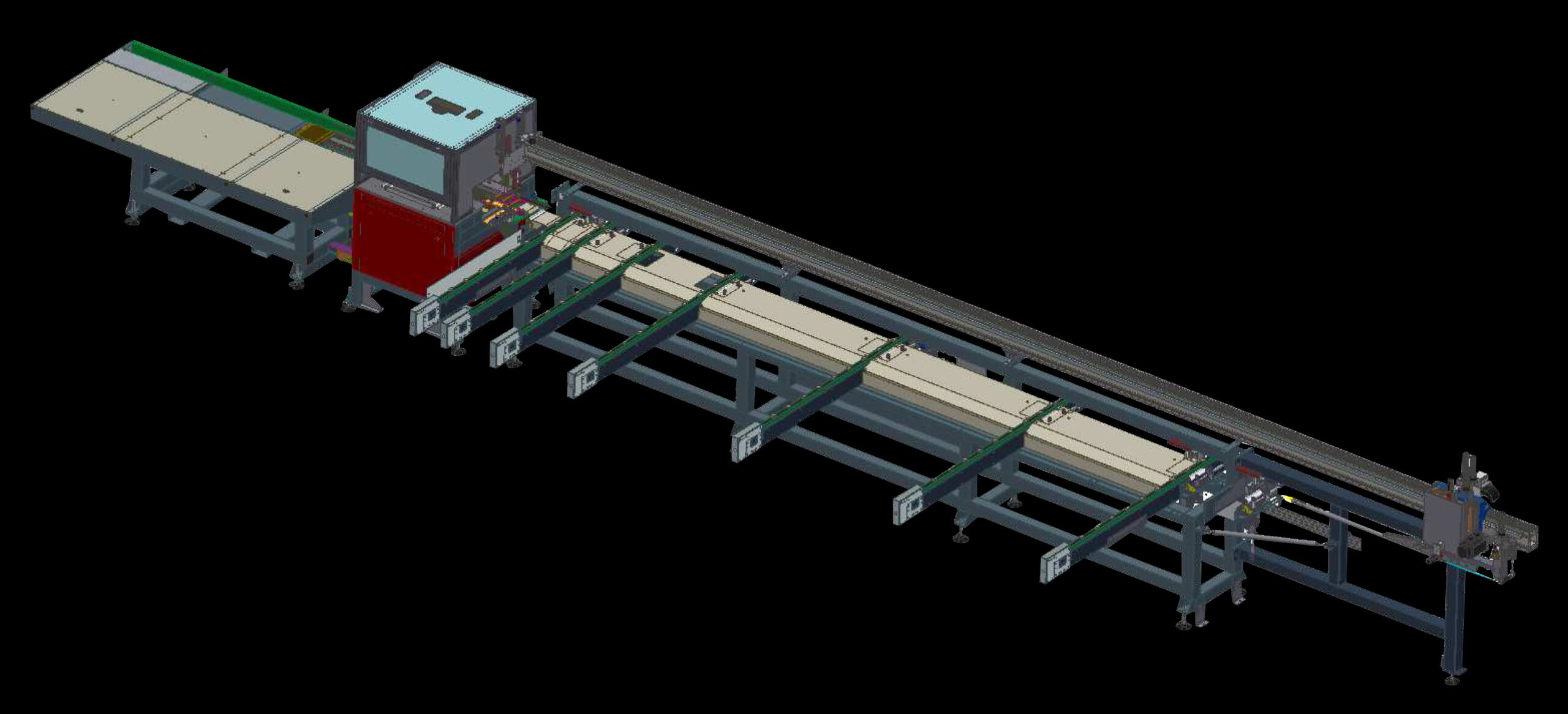

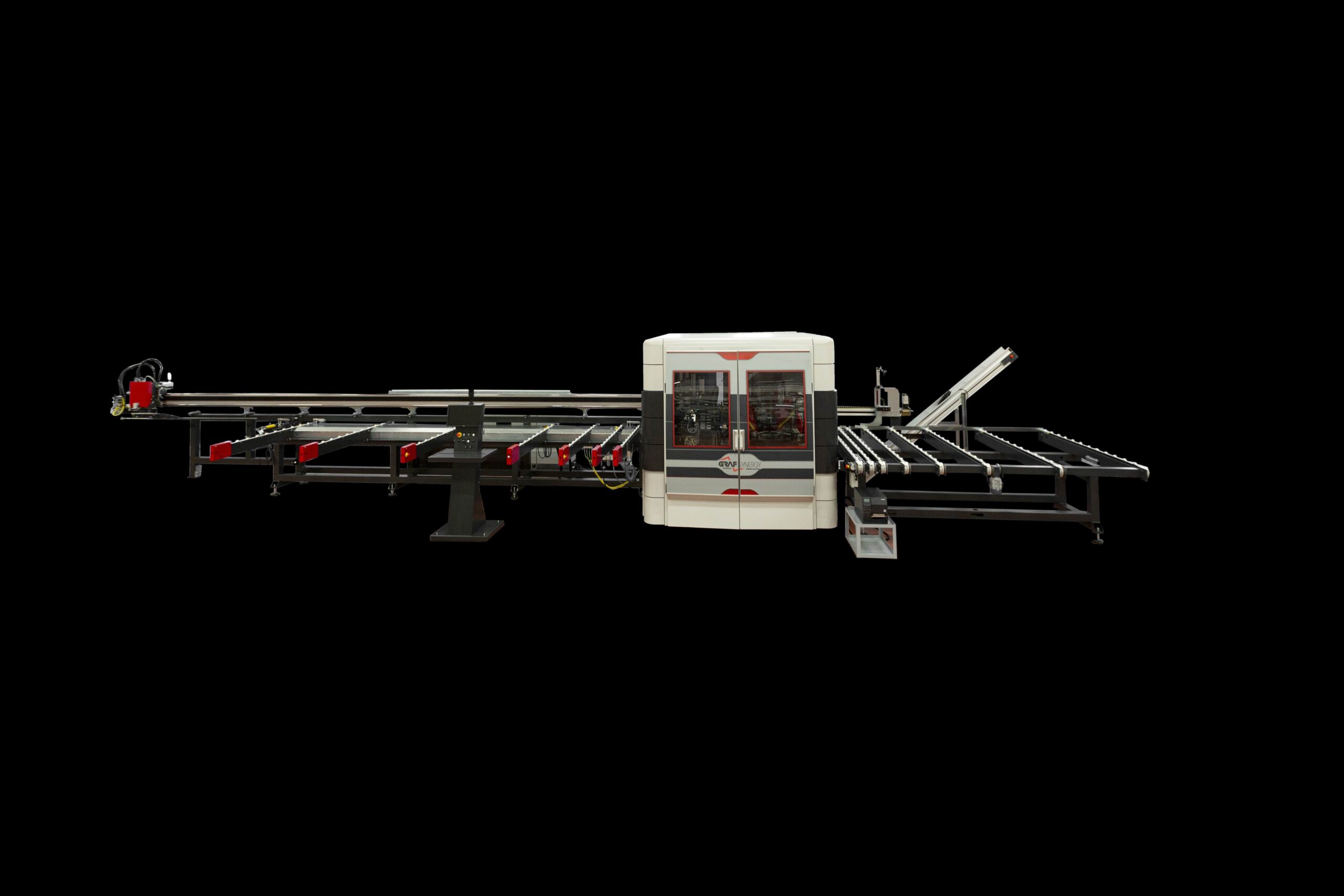

FAB CUT ALU is a 7-axis CNC cutting and machining centre designed to fully automate the processing of aluminium profiles. With its advanced configuration and GRAF Synergy technology, it allows all necessary operations to be performed in a single cycle: milling, drilling, notching, and angle cutting. The high-speed working module, combined with a precise upward-cutting blade system, ensures flawless results and consistent repeatability over time.

This solution is aimed at window manufacturers and industrial producers seeking reliability, precision, and a high degree of automation. The system optimizes the use of bars, reduces waste, and simplifies operational management through intelligent programming and control software.

Optimize the performance of the bars with the integrated GRAF Synergy software.

- Compact work center with high-speed multi-spindle machining

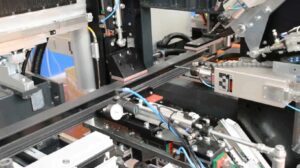

- Precise cuts even on not perfectly straight bars thanks to automatic alignment.

- Ideal for large productions: up to 100 windows per shift with just one operator.

Optional integration with header modules and fastening centers

5 Reasons to Choose the FAB CUT ALU

- Complete Automation with Bar Optimisation. GRAF Synergy software automatically imports production lists and optimises bar usage, reducing waste and increasing material yield.

- Maximum precision even on imperfect profiles. An innovative alignment system automatically straightens bars that are not perfectly straight, ensuring consistently accurate machining.

- Versatility in High-Speed Machining. The work module accommodates up to 12 High-Speed spindles (6 standard), allowing for all major operations on aluminium profiles.

- Perfect Cuts with CNC Upward Blade. The cutting module features a Ø 500 mm upward-moving blade, allowing for precise cutting angles (-45° / 90° / +45°) even on large sections.

- High performance with a single operator. Productivity of up to 100 windows per 8-hour shift, with streamlined management by just one staff member.

Product Details

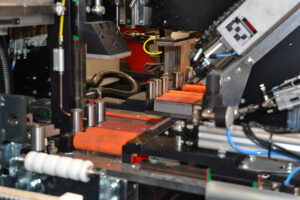

The work module is equipped with 6 High Speed spindles (expandable to 12), designed to perform all necessary operations on aluminium profiles.

Sizes

Length: 14,900 mm

Width: 3,400 mm

Height: 2,500 mm

Weight: 3.000 Kg

POWER SUPPLY and Consumption

Installed power: 20 kW

Power Supply: 400 V

Air consumption per cycle: 120 Nl/min

Minimum operating pressure: 7 bar

Performance

Productivity: up to 100 windows/shift*

Operators Required: 1

(*depending on the type of profiles and work required)

workable profiles

Length: 700 / 6,500 mm

Width: 40 / 130 mm

Height: 40 / 130 mm

Supported features and processes

- Holes for handles and hinges

- Markings and cutouts for locks

- Cylinder holes, ventilation, and custom machining

- Condensate drain holes

The profile is secured by a longitudinal axis that ensures stability and precision during every operation. The cutting module features a 500 mm diameter blade with CNC-controlled upward movement, allowing for precise and repeatable cuts at -45°, 90°, and +45°.

Available options

FAB CUT ALU is a fully customizable system designed to meet every production need. Upon request, it can be configured to include:

- An additional 6 high-speed spindles (total of 12)

- CNC bar gripping system on a two-axis prismatic guide

- Loading bars from 400 to 700 mm

- Blade Ø 550 mm for profiles up to 180 mm

- CNC blade rotation for intermediate cuts (variable angles)

- Tool breakage sensors

- Recovery System (optimisation of rework cuts)

- Fly Optimizer (automatic measurement of bar remnants)

- Stats (productivity analysis software)

- Motorized discharge table with output on the opposite side

- Soundproof booth, chip conveyor, vacuum cleaner, etc.

Technology and Automation

The technological heart of FAB CUT ALU is the proprietary software GRAF Synergy, which automatically manages every stage of production: from loading profiles to optimising lists, and even archiving production data. The intuitive interface simplifies daily use and allows for direct connection with business management systems. The machine is equipped for Industry 4.0, featuring remote connectivity, tele-assistance, predictive diagnostics, and advanced reporting capabilities.

Contact us to find out if FAB CUT ALU is the right solution for your production.