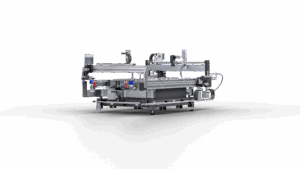

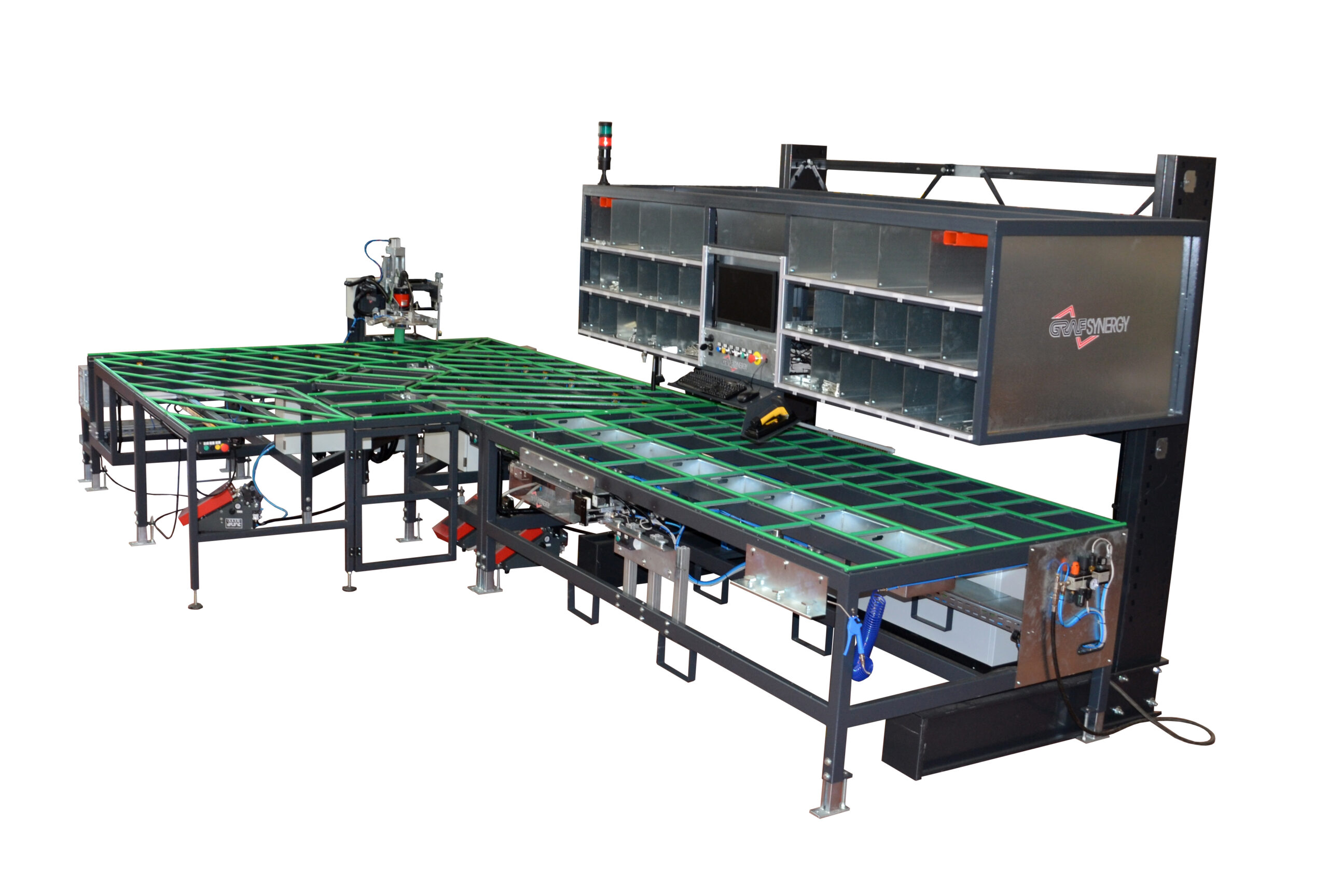

FAZ IV

Automatic machine for mounting hardware on PVC doors

Complete automation for hardware pre-assembly: increased speed, fewer errors, maximum productivity

Perfect if you want…

- Eliminate bottlenecks in the pre-assembly phase of hardware.

- Automating a process with a high incidence of human error

- Reduce the number of operators along the production line.

- Integrate hardware assembly into a 4.0 workflow with complete traceability.

- Working with the front side while exchanging hits.

- Maintain quick cycles and operational continuity

Request the technical brochure now or speak with an expert.

Complete automation for hardware pre-assembly: increased speed, fewer errors, maximum productivity

The FAZ IV is a workstation designed to automate the assembly and screwing of hardware onto PVC doors, significantly reducing cycle times and human intervention.

Consisting of 2 or 3 stations (preparation bench/benches + assembly table), it can be integrated into an automated production line and allows for the completion of a finished door leaf in just 50 seconds.

The system automatically manages multiple types of screws, selecting the correct one and autonomously adjusting the screw depth. Thanks to the intuitive graphical interface, even inexperienced operators can handle the process without errors. The entire structure is designed for the assembly of doors with a reversible stop, ensuring complete flexibility.

5 Reasons to Choose FAZ IV

- Ultra-fast cycle. Completes a full panel every approximately 50 seconds, regardless of size.

- Non-stop production. While one structure is being screwed together, the next one can already be pre-assembled: zero downtime.

- Automatic screw selection. The system recognises the hardware and selects the correct screw, also adjusting the depth.

- Guided Interface. The software assists the operator step by step, even in the presence of complex variations.

- Complete integration. Compatible with automated transport systems and designed for vertical or horizontal exit.

Product Details

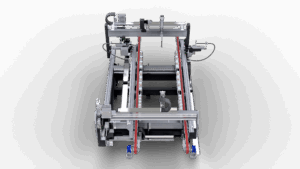

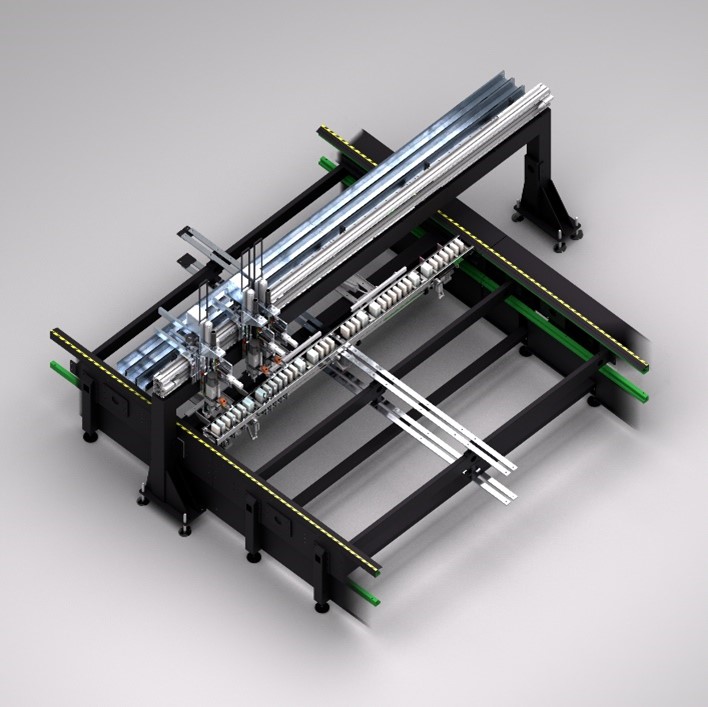

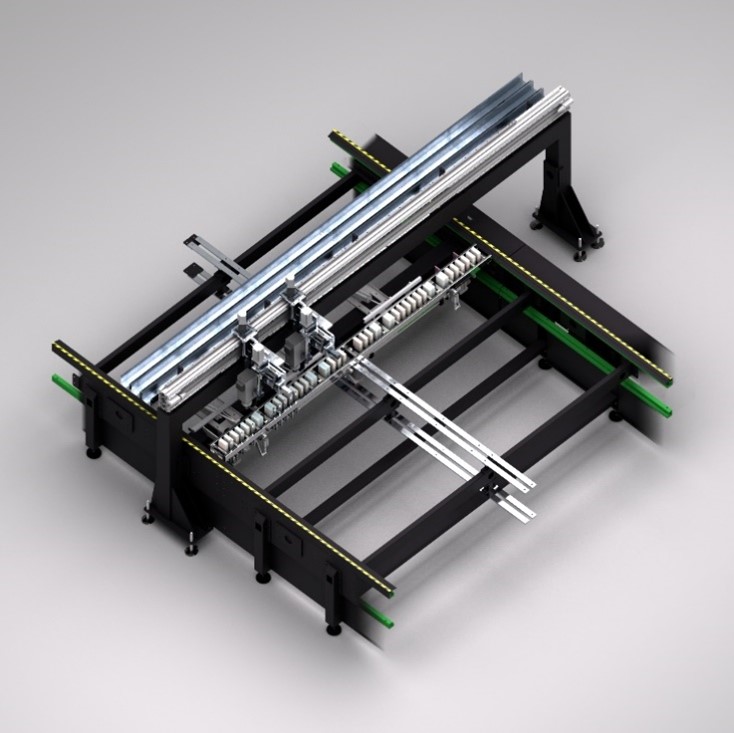

The FAZ IV bench consists of:

- Preparation Stations: one or two, with guidance on the placement of items and compartment indications.

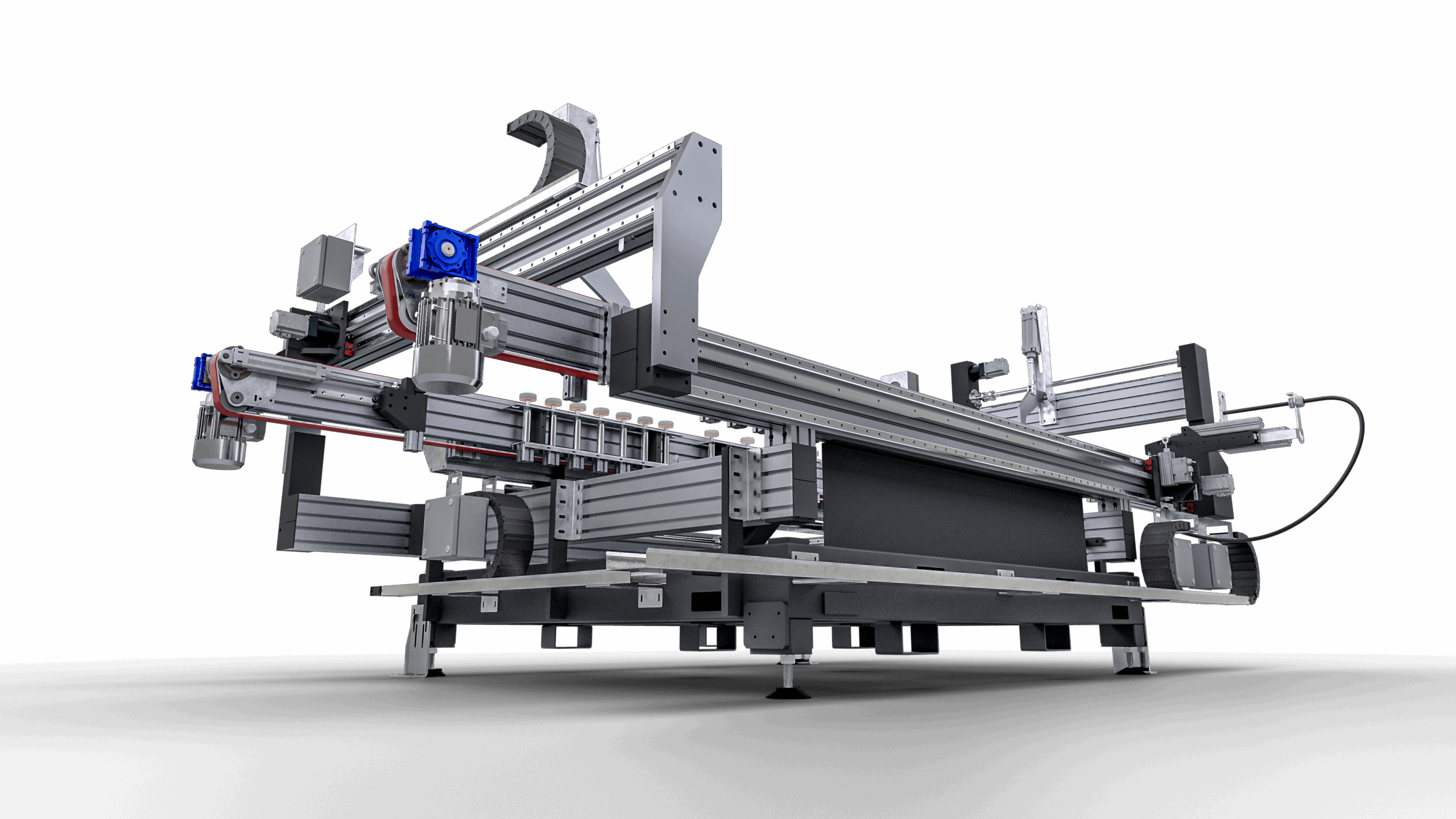

- Automatic Screw Driving Table: a portal with 4 High-Speed Screwdrivers, automatic depth adjustment, and screw selection.

The entire process is computer numerically controlled, with automatic movement between stations. The system is also optimized for tool changeover.

Dimensions (Standard Bench + Screw Portal)

Length: 7,950 mm

Width: 3,000 mm

Height: 2,510 mm

Weight: 6.000 kg

Additional bench dimensions

Length: 3,000 mm

Width: 2,000 mm

Height: 2,510 mm

Weight: 1.580 kg

Performance

Cycle time: ~50 sec/part*

(*depending on profile, hardware, and dimensions)

Required operators: 1 – 2

Working door dimensions

Max: 106.3 x 59.1 inches

Min: 13.78 x 13.78 inches

Workable profiles

Max width: 130 mm

Minimum width: 50 mm

POWER SUPPLY and Consumption

Installed power: 9 kW

Voltage: 400 V

Air consumption: 500 Nl/min

Minimum pressure: 7 bar

Optional and configurations

The FAZ IV is available in various configurations:

- Hardware programming based on window type

- Morse group for mounting stulp on the preparation bench

- Variant for the use of special screws or non-standard sizes

- Horizontal exit station or with automatic verticalization

Advanced technology and automation

The FAZ IV is equipped with:

- Proprietary software with an intuitive graphical interface

- Complete traceability of processing

- Remote diagnostics

- ERP Setup

- Industry 4.0 ready: maximum control and integration in business digital processes

Do you want to automate hardware assembly without compromise?

Download the full brochure or contact us for a tailored consultation. FAZ IV is the solution for systems looking to enhance efficiency, speed, and control.