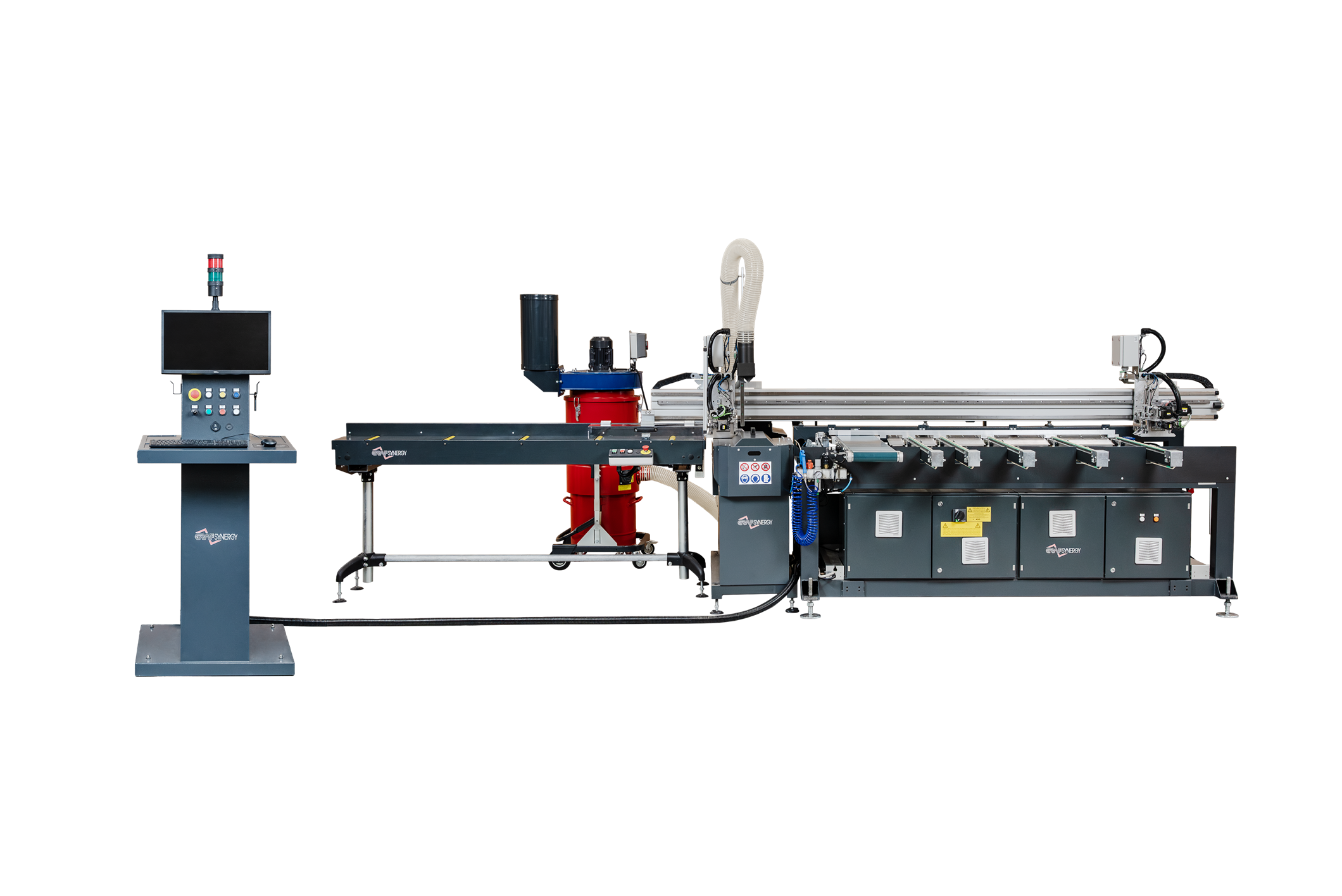

GS 200 AS

Compact cutter for PVC glazing beads

Precise cutting, compact structure: the ideal solution for quick and high-quality machining

Perfect for:

- Workshops with limited space that want to maintain high-quality craftsmanship.

- Who wants a simple yet precise system for cutting glazing beads?

- Small productions that don’t want to give up on CNC technology.

- Who works with different types of glass stops without having to change the templates?

- Anyone looking for an intuitive and ready-to-use car

Request the technical brochure now or speak with an expert.

Automatic and intelligent cutting with consistent precision

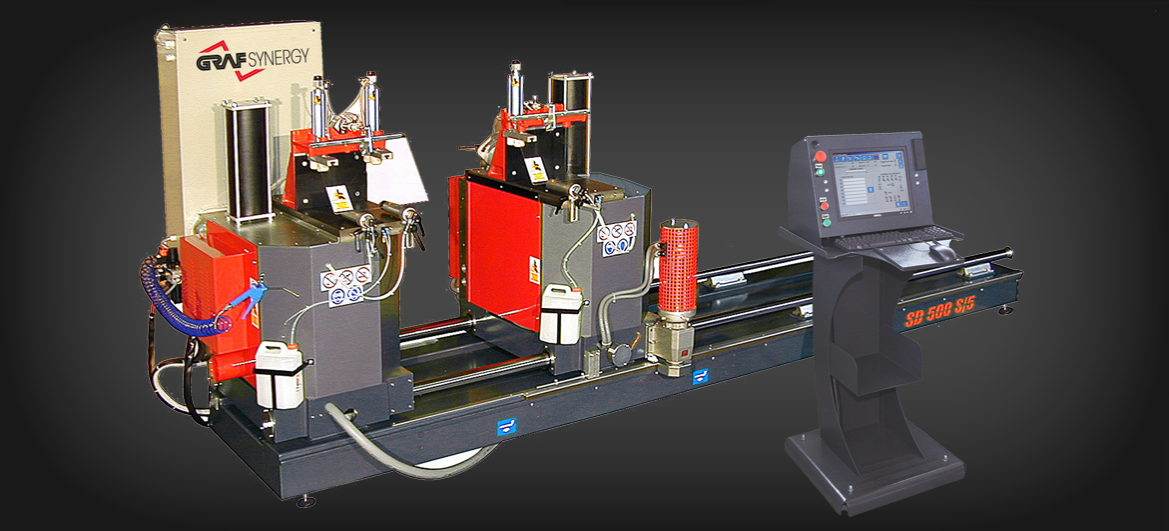

The GS 200 AS is a controlled-axis cutting centre designed for the automated processing of PVC glazing beads.

Made with a steel and aluminium structure, it combines strength and reliability with a fully automated management of the production process.

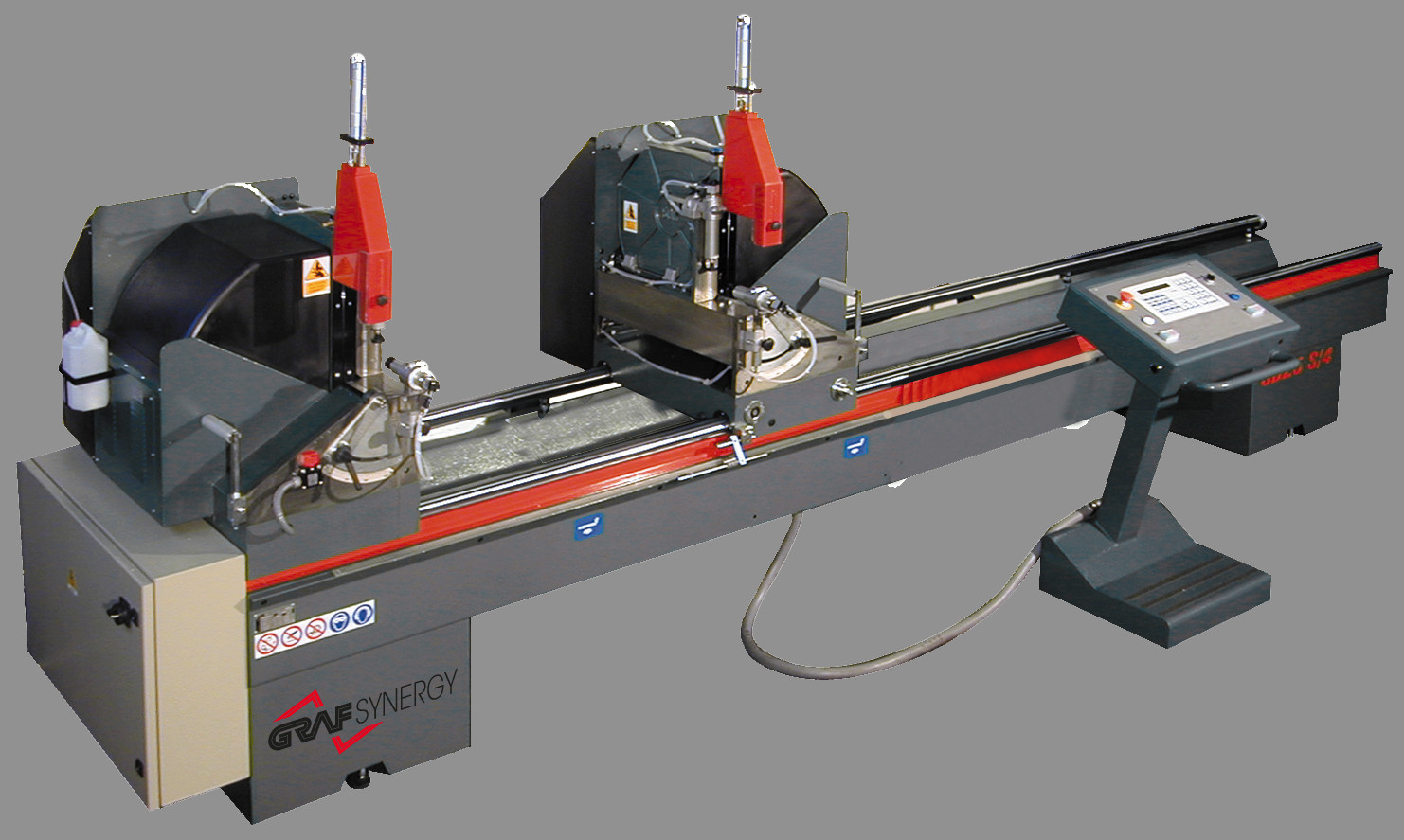

The system features a mobile cart with a fixed 45° tilt, two main blades with a diameter of 200 mm, and two secondary blades with a diameter of 98 mm, perfect for precisely finishing the ends of the mounting foot.

The operator’s role is limited to loading the bars and unloading the finished pieces.

Why choose the GS 200 AS?

- Compact Precision. Lightweight yet sturdy structure with controlled feed for consistently accurate cuts.

- High-quality finish. High-speed rotating blades for a clean cut even on complex profiles.

- Limitless Versatility. New glass stops can be managed directly through software, without the need for physical adjustments.

- Real Assembly Simulation. The gripping system replicates installation conditions, preventing defects caused by bending.

- Automatic workspace cleaning. Integrated suction for chips and debris, creating a tidy and safe environment.

Product Details

The GS 200 AS is designed to make precise cuts on two glass stops simultaneously, accurately replicating the conditions of the final installation.

The software automatically sets the optimal parameters for each type of profile selected from the display.

Sizes

Length: 1,200 mm

Width: 700 mm

Height: 1,300 mm

Weight: 250 kg

Performance

Operations: manual

Operator required: 1

POWER SUPPLY and Consumption

Installed power: 1.5 kW (+ extractor 1.5 kW)

Voltage: 400 V three-phase

Minimum pressure: 7 bar

Air consumption: 60 Nl/min

Workable profiles

Profile height: from 10 to 35 mm

Profile Width: from 18 to 45 mm

Optional features and customizations

The GS 200 AS model is optimized to deliver high performance right from its base configuration. There are no additional options available; everything is already included to ensure efficiency and precision from the very first use.

Simplified technology and control

With a simple and intuitive interface, the machine allows users to select the profiles to work on and automatically apply preconfigured parameters. The numerical control of the axes ensures consistent precision and makes it easy to introduce new profiles without the need for additional equipment.

Bring precision and compactness to your lab: request a demo or your personalised quote for the GS 200 AS now.