HDH

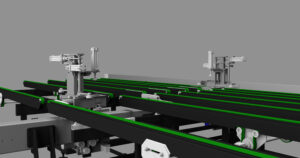

CNC table for automatic drilling of PVC frames

Maximum precision in hinge drilling, directly downstream from the welder.

Perfect if you want…

- Automate hinge drilling without the need for specialized operators.

- Reduce cycle times in post-welding.

- Free up valuable space in the workshop by removing the cooling table.

- Avoid waste and machine downtime caused by chips.

- Integrate a user-friendly and intuitive machine.

Request the technical brochure now or speak with an expert.

Maximum precision in hinge drilling, directly downstream from the welding machine.

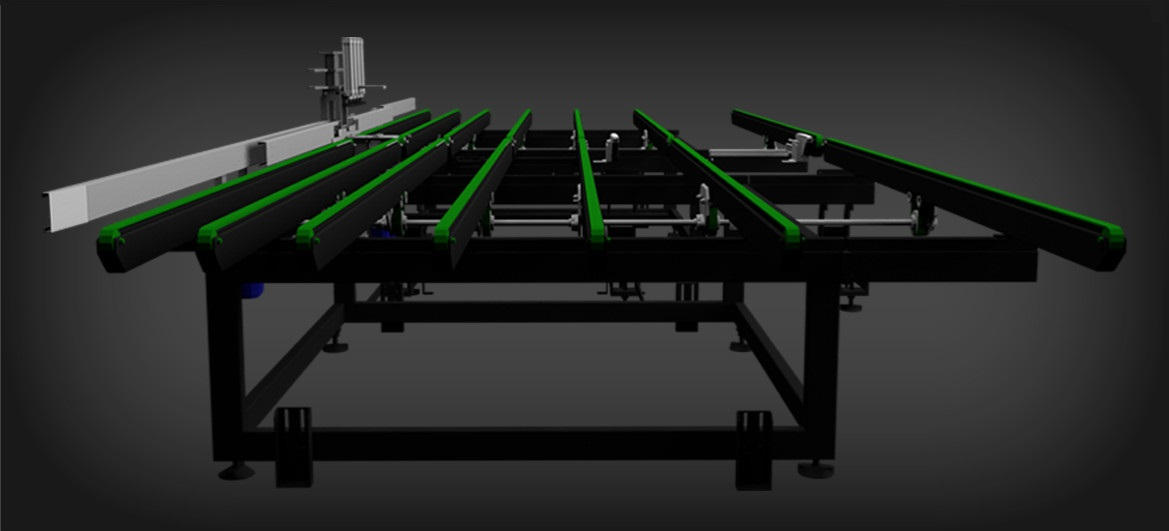

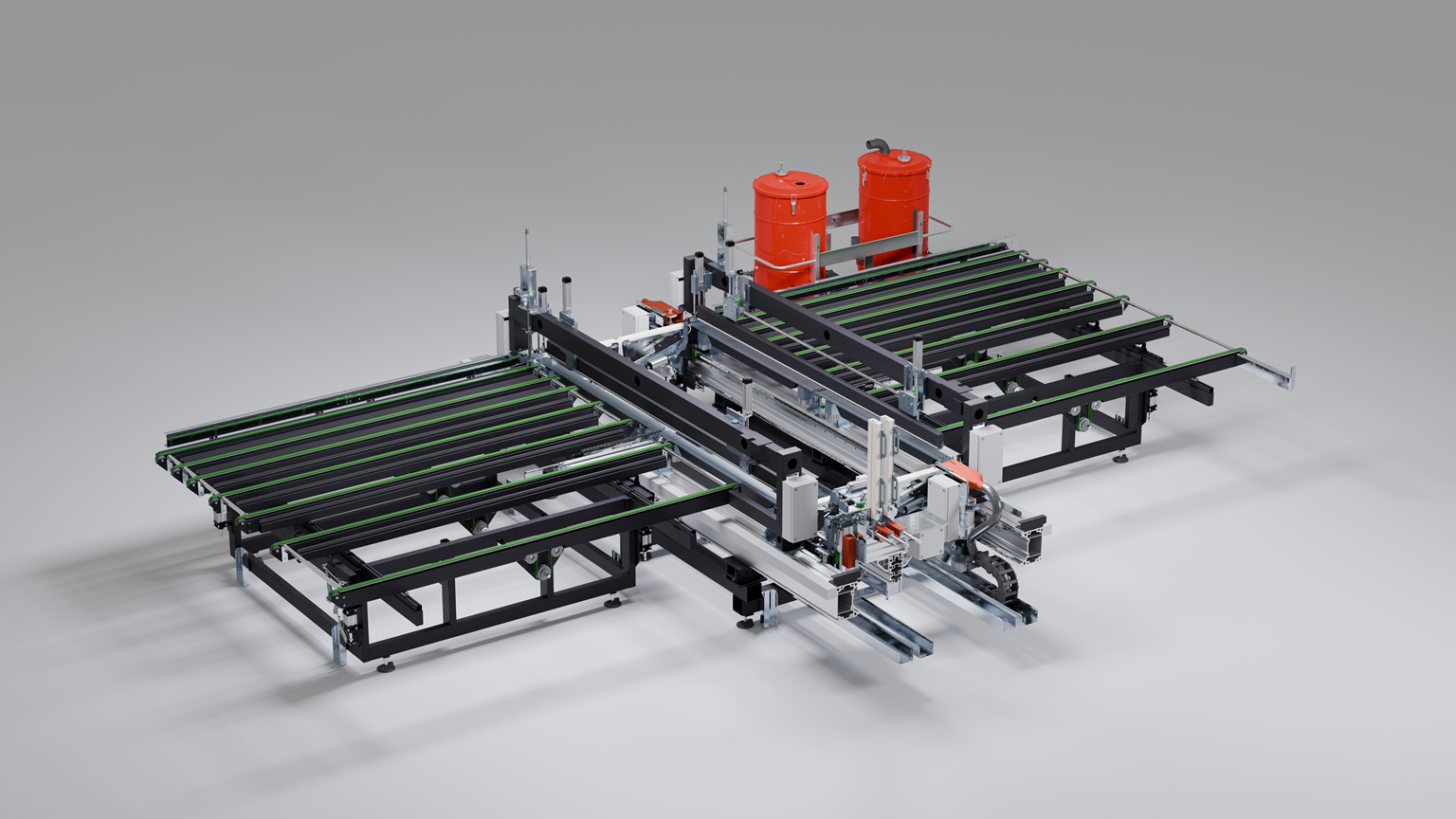

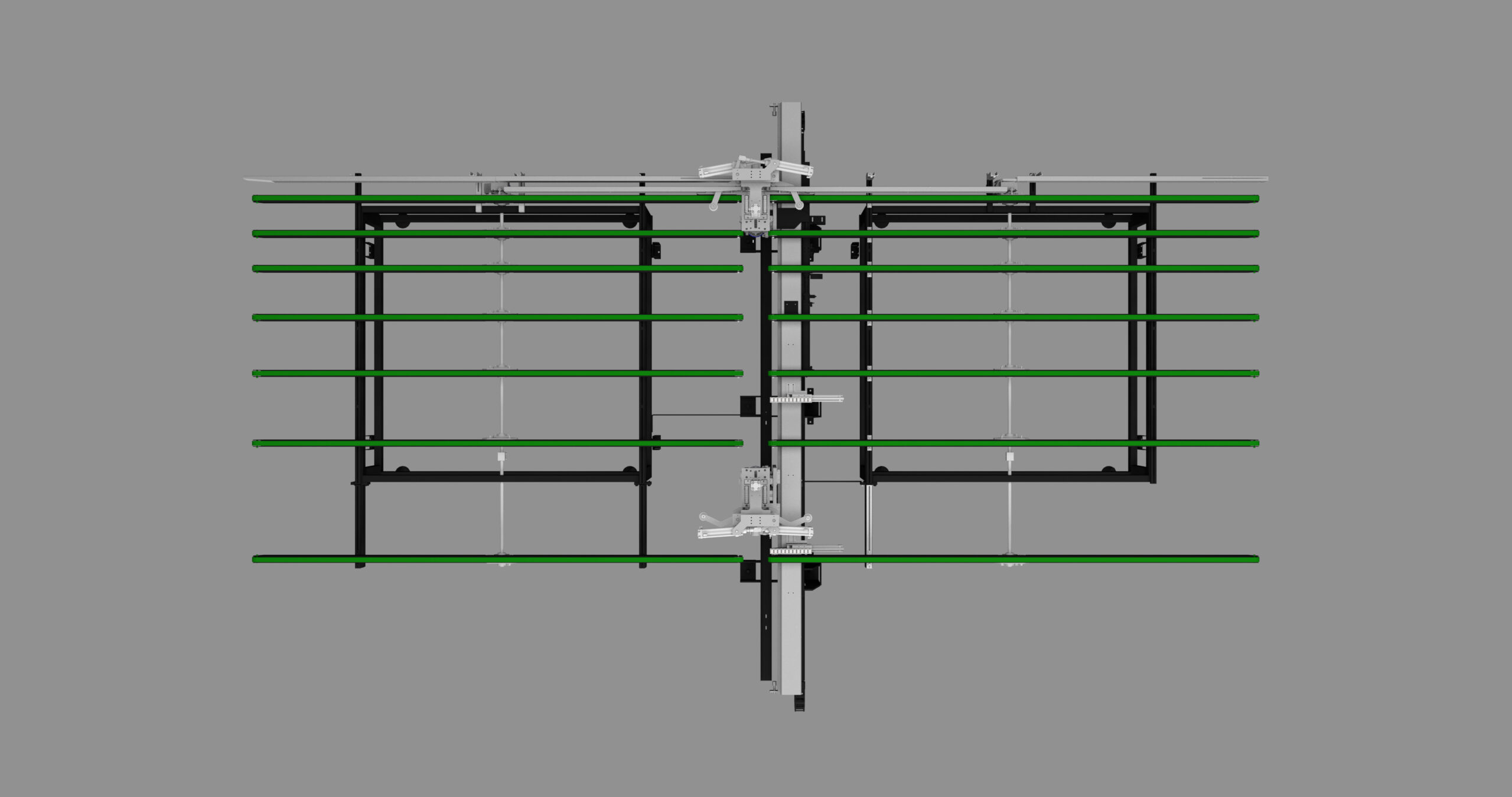

HDH is a 3-axis CNC machine designed to fully automate the drilling of hinge mounting holes on PVC frames, immediately after welding.

Its online integration allows for replacing the cooling table, optimising space without sacrificing productivity.

Thanks to automatic reference measurements and active drilling depth control, it ensures repeatable accuracy and zero rework. Ideal for fixture manufacturers looking to enhance efficiency and reduce assembly errors.Adapt this content naturally and fluently into US English. Content:

5 Reasons to Choose HDH

- Labor Cost Reduction. It autonomously handles the relocation and drilling of the frame with just one operator.

- Maximum precision. The holes are positioned based on the internal width of the glazing groove, automatically measured on the welded frame.

- Optimised Dimensions. It replaces the cooling table, seamlessly integrating into the line without increasing the footprint.

- No machine downtime. The integrated chip breaker system eliminates waste without the risk of jams or blockages.

- Simple and Immediate Use. Quick parameter setup, intuitive interface, suitable for operators with no CNC experience.

Product Details

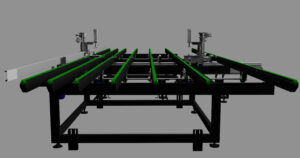

Designed to integrate into automated lines, the HDH allows for simultaneous and precise drilling of both frame uprights immediately after welding. The 2 controlled ascent drilling heads, powered by brushless motors, ensure consistent speed and quality over time. The pneumatic clamps, both horizontal and vertical, guarantee perfect locking of the frame throughout the entire processing.

Sizes

Length: 8,000 mm

Width: 4,500 mm

Height: 1,800 mm

Weight: 1.500 kg

Performance

Up to 240 frames/8h*

(*productivity varies depending on the type of frame and the line used)

Required operators: 1

POWER SUPPLY and Consumption

Installed power: 5 kW

Power Supply Voltage: 400 V

Minimum pressure: 8 bar

Air Consumption: 10 Nl/min

Supported features and processes

Main Processes:

- Hinge drilling for PVC frames

Optional and configurations

The HDH model is provided in standard configuration without any additional options, ensuring maximum operational simplicity and reliability. Each unit comes ready for integration into the production line, with no need for customizations.

Technology and automation

Equipped with a 3-axis CNC and brushless control for head elevation, the HDH utilises intelligent algorithms to optimise the drilling position based on the actual measurements of the frame. The automatic zeroing sequence at the end of the process ensures a quick restart without manual intervention. The human-machine interface is designed for fast configuration, with parameter storage and production recipe recall.

Request the complete brochure or a personalised consultation now.

Want to find out how HDH can enhance your productivity?

Contact our technical team for a demo or a customised quote.