HDHS

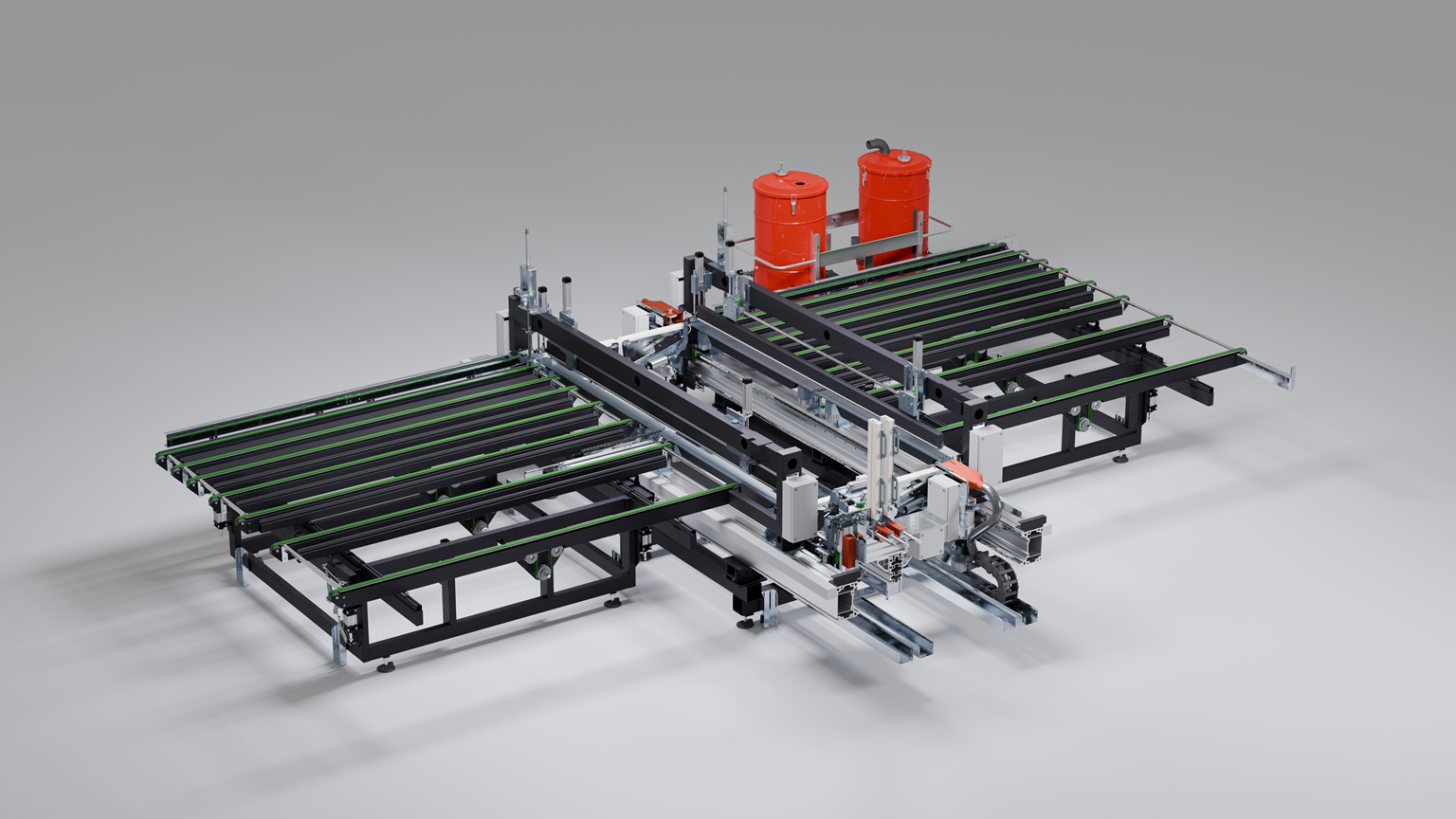

Automatic table for hinge holes on PVC doors

High-precision automatic drilling, immediately after welding

Perfect if you want:

- Automate hinge drilling to reduce manual interventions.

- Eliminate positioning errors with precise references.

- Reduce the clutter downstream of the welder.

- Integrate a process that is often manual into an online system.

- Enhance the quality and consistency of the doors.

- Work with just one operator.

Request the technical brochure now or speak with an expert.

Maximum efficiency in the post-welding phase

HDHS is the automatic machine designed by GRAF Synergy to optimise the drilling phase of hinges on PVC doors.

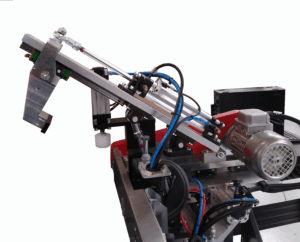

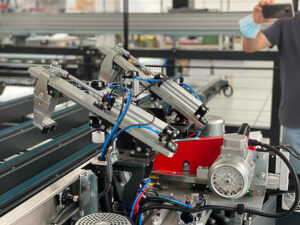

Thanks to its bi-directional drilling head and precise pneumatic locking, HDHS ensures fast, repeatable results that are perfectly aligned, starting from the most reliable geometric reference: the outer edge of the frame.

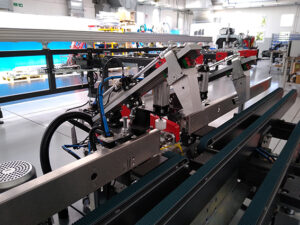

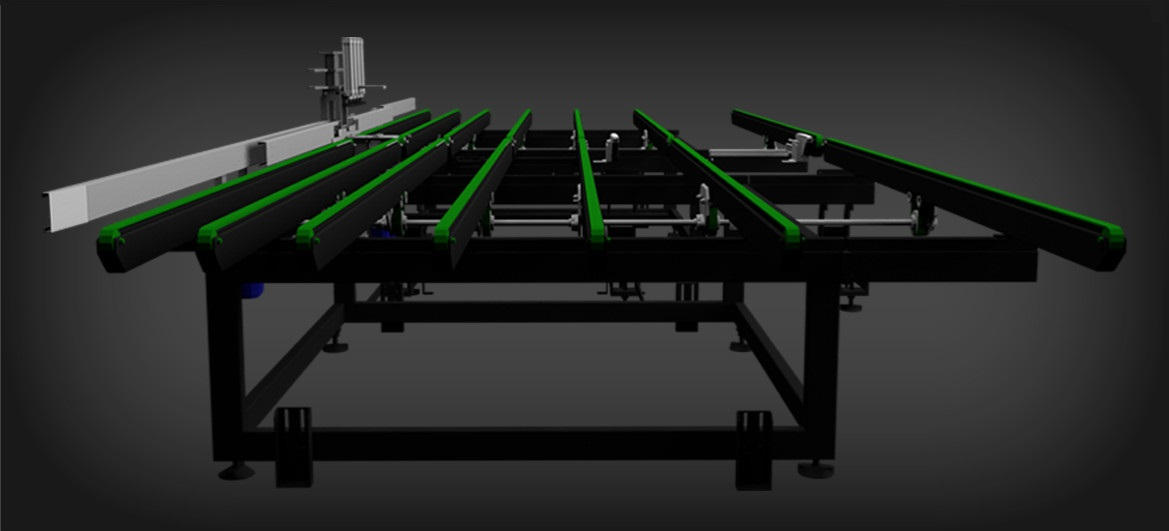

Designed to be installed immediately after the welder, the HDHS not only automates a critical phase of the process but can also completely replace the traditional cooling table, reducing space and labour requirements.

A perfect ally for window and door manufacturers looking to boost productivity, eliminate manual errors, and seamlessly integrate hinge processing into a compact line.

5 Reasons to Choose HDHS

- Automatic and precise drilling. Thanks to the mechanical positioning of the head and the reference on the outer edge of the door, each hole is perfectly aligned.

- Fewer operators, fewer errors. The machine autonomously moves and removes the frame, allowing a single operator to manage the entire process.

- Smart Integration. It can replace the cooling table: same footprint, one extra function, no wasted time.

- Consistent quality in every cycle. The drilling depth is managed by an automatic regulator: each panel is ready for assembly, without any touch-ups.

- Simple and straightforward interface. Intuitive setup and management: even inexperienced staff can operate confidently.

Product Details

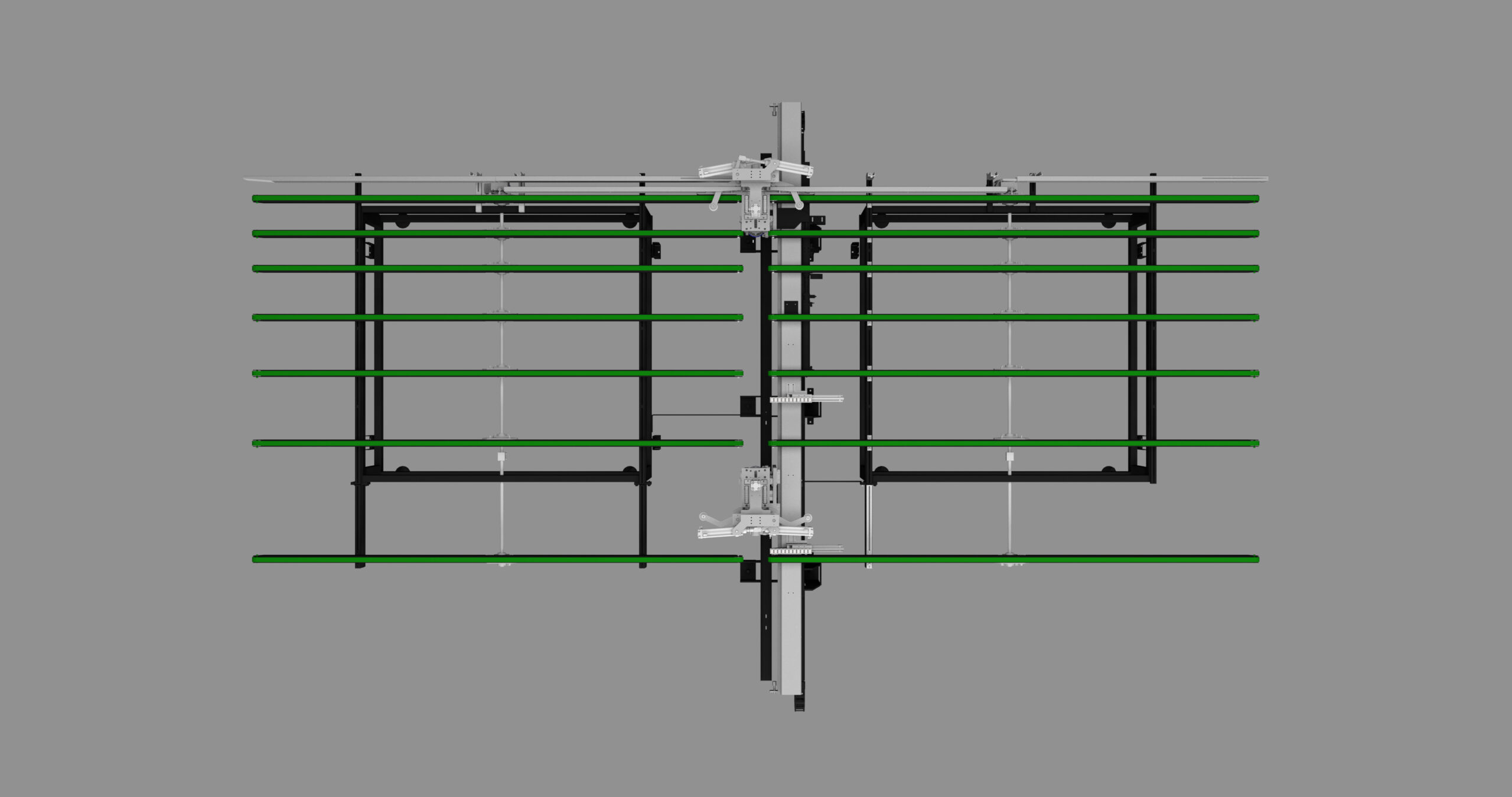

HDHS is specifically designed for drilling hinge holes on PVC doors. Its compact and functional structure houses a bidirectional drilling head with mechanical positioning, along with a set of pneumatic clamps (2 horizontal + 2 vertical) that ensure the door is securely held in place during processing.

Sizes

Length: 4,000 mm

Width: 1,400 mm

Height: 3,500 mm

Weight: 1.200 kg

Performance

Productivity: depends on the speed of the connected welder.

Required Operators: 1

POWER SUPPLY and Consumption

Installed power: 2 kW

Power Supply Voltage: 400 V

Minimum operating pressure: 7 bar

Air consumption per cycle: 10 Nl/min

Workable profiles

Minimum dimensions: 370 x 300 mm

Maximum dimensions: 2,800 x 1,000 mm

Supported features and processes

The entire drilling cycle is optimized for quick turnaround times and absolute repeatability, eliminating the need for rework or manual corrections.

Main processes: Hinge holes on doors after welding

Optional and configurations

HDHS can be configured upon request to accommodate various levels of automation and production layouts.

Among the available options:

- Head positioning on a controlled axis: for greater flexibility and integration with CNC management software

- Custom configurations for compact layouts or dedicated production workflows

Thanks to its modularity, HDHS is suitable for both small semi-automatic lines and fully automated systems.

Technology and automation: precision at your service

The machine is operated by a highly reliable pneumatic logic system, integrated with an automatic depth regulator that ensures consistency in every operation.

Available in a version that can be integrated into digital systems, HDHS can be set up for Industry 4.0 and connected via application tags for remote control, backup, and predictive assistance.

GRAF Synergy provides comprehensive technical support, from installation and operational training to advanced cloud maintenance.

Do you want to make drilling cabinet doors faster and more precise?

Download the brochure to discover all the technical details and available configurations. Contact us for a tailored quote or to arrange a live or remote demo of the HDHS system. Our team is here to assist you in integrating this solution into your production line.