RMA

Automated workstation for inputting feedback on PVC and aluminium frames

Automate the fastening of fixtures and free up operational resources

Perfect if…

- Automate the placement of feedback without human intervention.

- Reduce frame assembly times and optimise the production flow.

- Freeing up manpower for more strategic activities

- Ensure absolute precision in securing the components.

- Increase productivity in a predictable and consistent manner.

Request the technical brochure now or speak with an expert.

Automate the fastening of supports and free up operational resources.

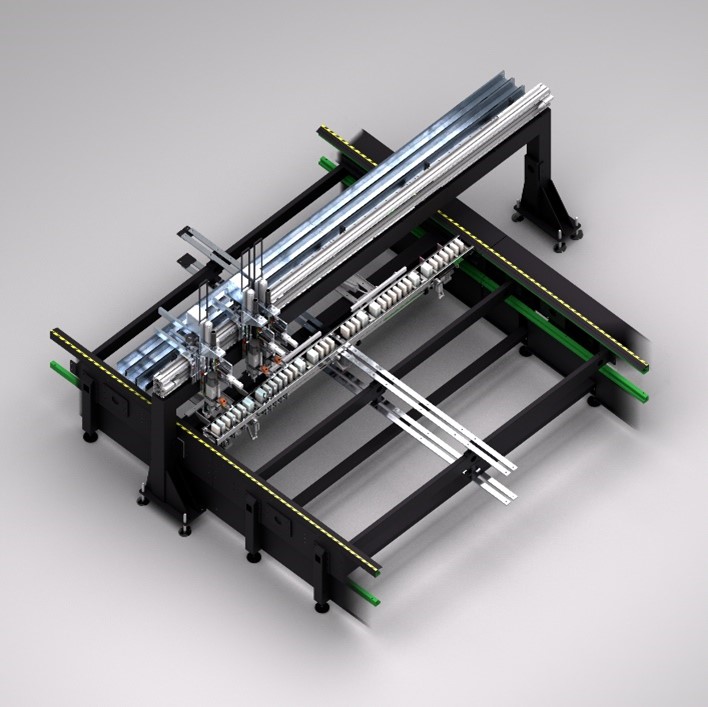

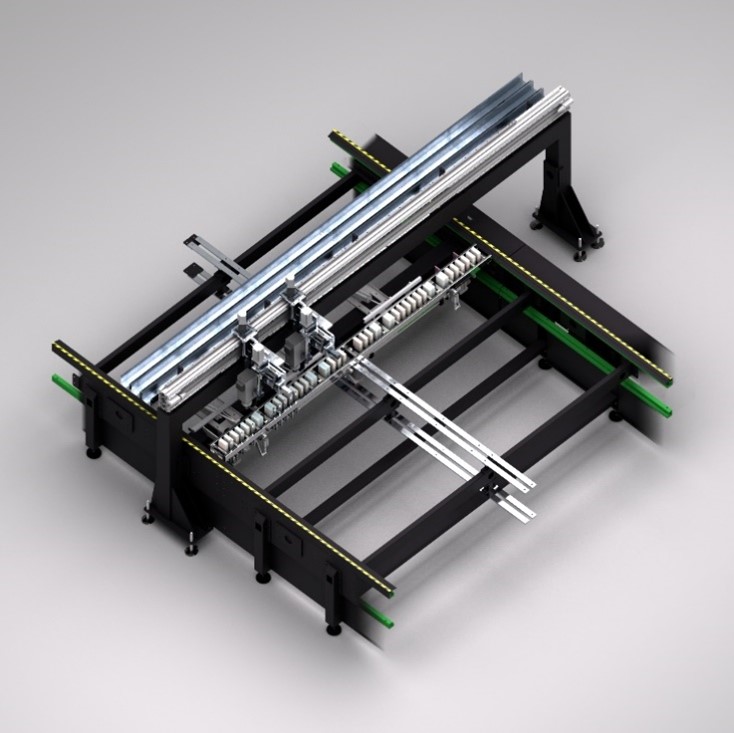

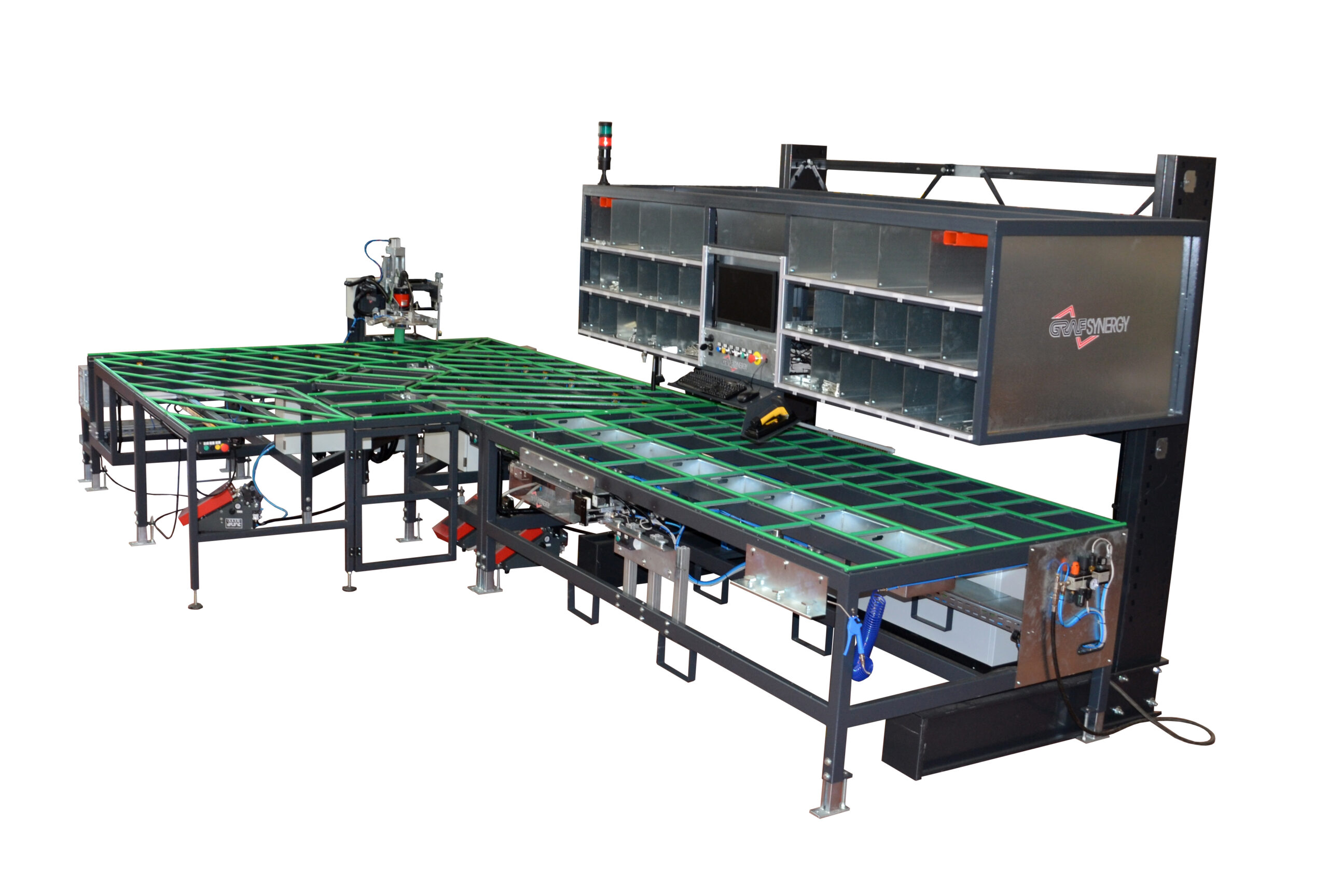

The RMA model from GRAF Synergy is an innovative workstation designed to fully automate the insertion and fastening of supports on PVC and aluminium profiles.

Thanks to an intelligent anthropomorphic arm, the system identifies the type of profile, selects the correct fitting from those available, positions it precisely, and automatically secures it with a high-speed screwdriver.

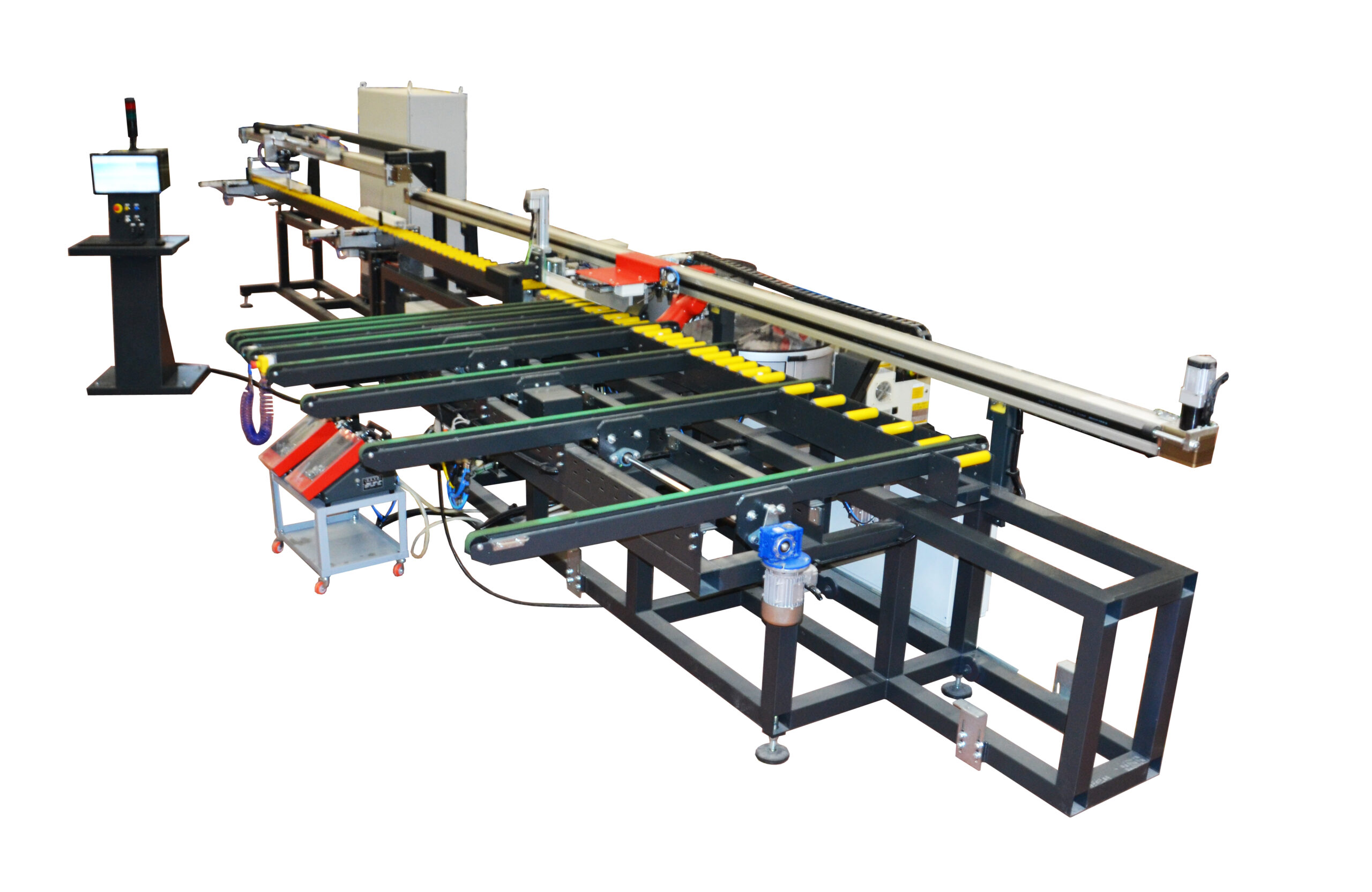

The result? Reduced processing times, lowered operational costs, and only one operator needed, who can focus on other high-value tasks. The RMA seamlessly integrates into automated production lines or can operate as a stand-alone unit.

5 Reasons to Choose RMA

- Total operational autonomy. No manual intervention is required: the robotic arm handles the entire cycle of selection, positioning, and fastening of the components.

- Intelligent Positioning Control. An integrated verification system checks the alignment of profiles and reports any deviations, ensuring accuracy and reducing waste.

- Integrated buffer and multi-feedback management. The system can operate on at least two profiles simultaneously and manage up to 4 feedbacks and 2 different types of screws.

- Speed and Reliability. With an average speed of 1 screw every 2.5 seconds, productivity is ensured even with large volumes.

- Smooth integration with other machines. The RMA works in synergy with reinforcement fastening centres and other modules in the line, adapting to every production requirement.

Product Details

The RMA work center is designed to simplify and automate the input of feedback on profiles for fixtures.

Sizes

Length: 3,800 mm

Width: 6,500 mm

Height: 1,500 mm

Weight: 1.000 kg

Performance

Average screw driving speed: 1 screw every 2.5″ (depending on the type of screw and profile)

Operators needed: 1

power supply and Consumption

Installed power: 7.5 kW

Voltage: 400 V

Air consumption per cycle: 80 Nl/min

Minimum operating pressure: 7 bar

Workable profiles

Length: from 500 to 3,200 mm (up to 5,000 mm upon request)

Width: 40 – 130 mm

Height: 40 – 180 mm

Supported features and processes

The structure includes:

- 1 anthropomorphic arm for the precise selection and placement of fixtures

- 1 high-speed screwdriver for quick fastening to the frame

Main Processes:

- Automatic feedback selection

- Precise positioning on the profile

- Automatic screwing

The system can operate in stand-alone mode or be integrated into a GRAF Synergy automated line.

Optional settings and configurations

The RMA model comes in a standard configuration without any additional options, ensuring maximum efficiency and ease of use.

However, it is possible to customize the integration according to the customer’s production layout and match the RMA with complementary modules.

Technology and automation

The heart of the RMA is a fully automated and independent system, powered by brushless motors with independent positioning on two axes, ensuring maximum operational precision.

The system is designed to operate in synergy with Industry 4.0 systems, with the capability to integrate with management software, monitoring systems, and remote assistance solutions through TAG Application.

Do you want to eliminate manual tasks and improve your productivity?

Contact us now for a personalised consultation or download the full technical sheet for the RMA.