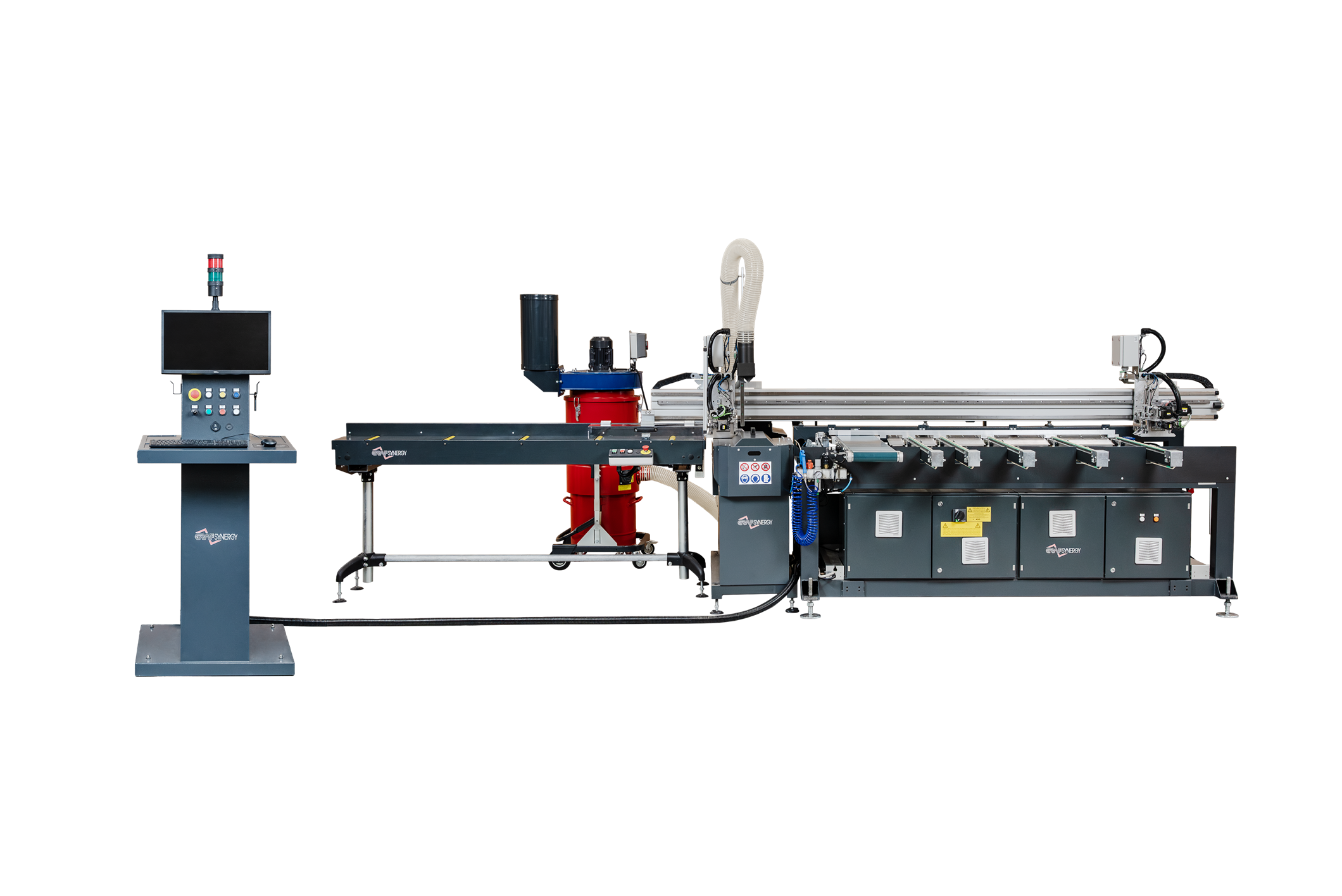

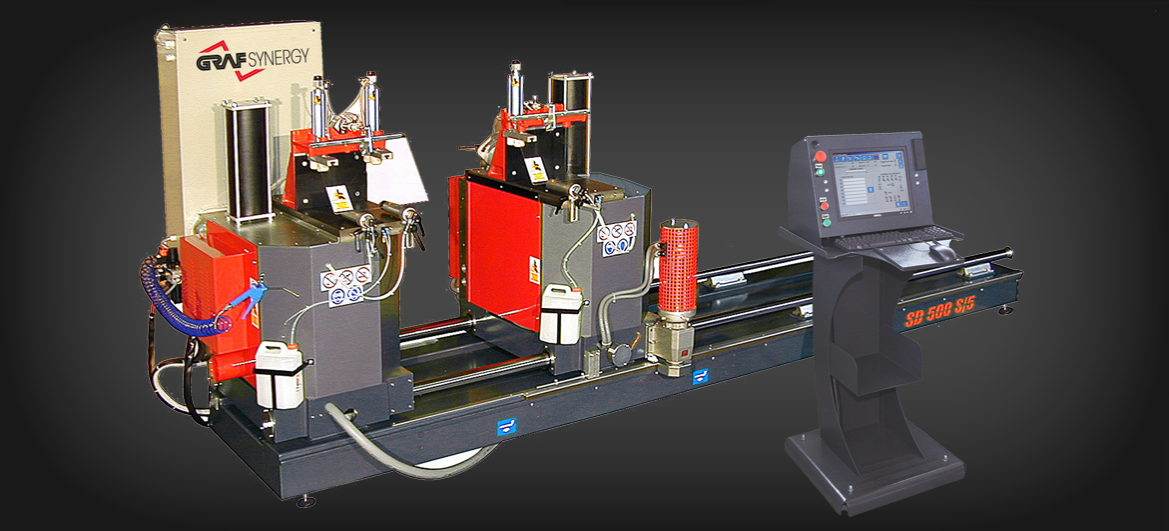

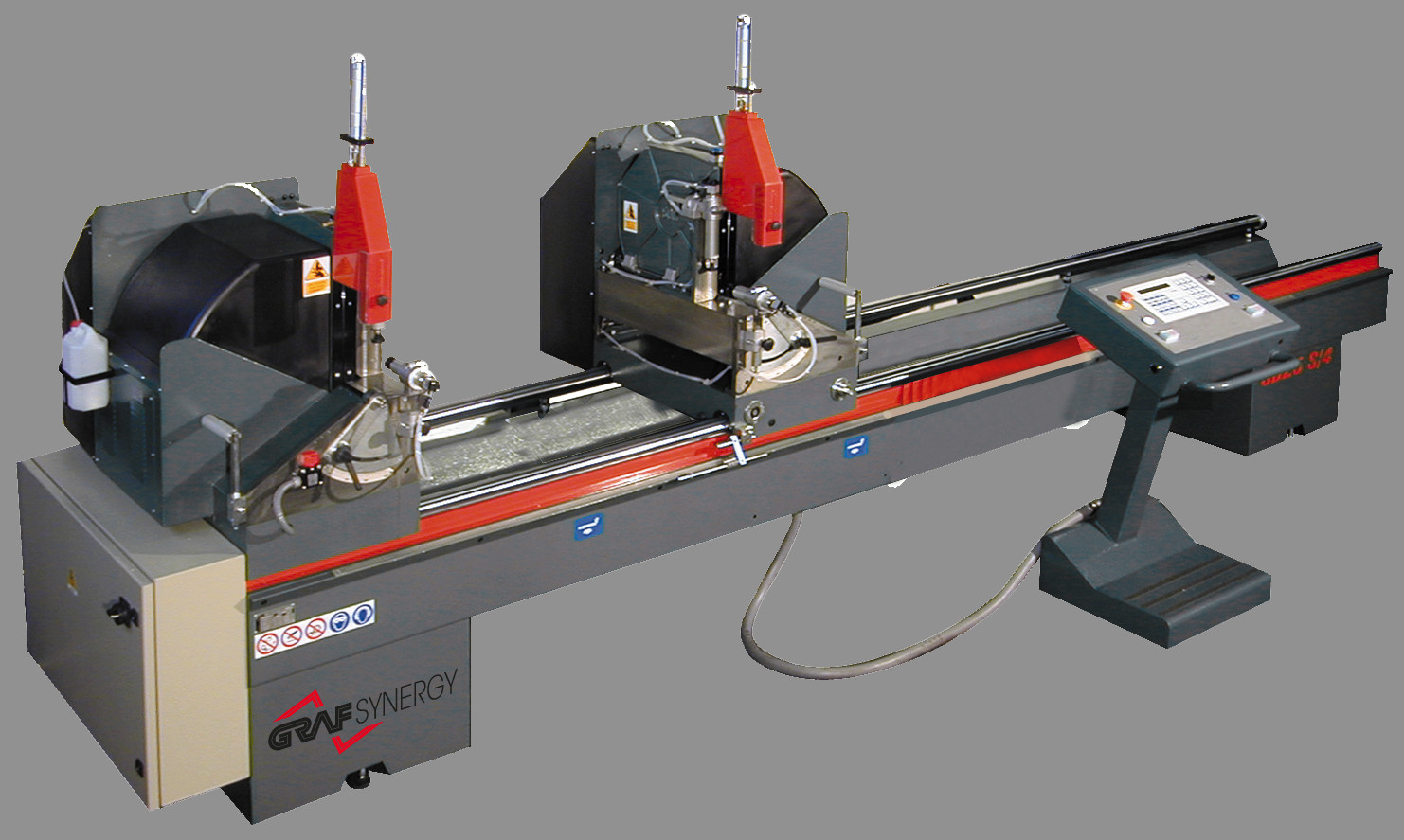

SD 26

Double miter saw for cutting PVC and aluminium profiles

Precise cuts, continuous production: the robust and flexible solution for every window and door manufacturer

Perfect for:

- Workshops looking for a precise and reliable machine for mass production and special parts.

- Those who work with both PVC and Aluminium

- Who wants to reduce the margin of error in angled cuts?

- Companies looking to optimize waste through intelligent systems

- Manufacturing plants looking to automate without losing control.

Request the technical brochure now or speak with an expert.

Smart cutting and sturdy structure for flawless results

The SD 26 is a dual-head oil-pneumatic cutting machine with electronic control, designed for high-precision cutting of PVC and aluminium profiles.

Equipped with a fixed head on the left and a movable head on the right, it allows for automatic positioning of the cutting length thanks to a CNC-controlled axis.

The machine stands out for its high-strength steel and aluminium structure, as well as the reliability of its two-handed control system, which ensures operational safety even in demanding work environments.

The Ø 500 mm retractable blades are equipped with carbide inserts and a “Venturi Effect” cooling system to ensure clean and long-lasting cuts.

Why choose the SD 26?

- Wide angle flexibility. Allows cuts from -22.30° to +22.30° with manual adjustment of intermediate angles, providing maximum production flexibility.

- Precision even on shorter cuts. The pneumatic system for ‘Short Cutting’ on the left head allows cuts shorter than the minimum distance between the two heads (down to 170 mm).

- Perfect profile clamping. Equipped with vertical and horizontal pneumatic clamps that ensure the stability of the workpiece at every stage of the cutting process.

- Intermediate support for long profiles. A crucial element for working with large profiles, reducing vibrations and improving accuracy.

- Built to Last. The reinforced base and high-strength framework ensure structural rigidity and long-term reliability.

Product Details

The SD 26 performs precise cuts on PVC and aluminium profiles, including angled cuts with predefined angles (90°, 45°, -22.30°) or adjustable manually. The two front descending blades ensure a clean cut without burrs, making it ideal for short and shaped pieces.

Sizes

Length: 5,100 mm

Width: 1,200 mm

Height: 2,000 mm

Weight: 950 kg

Performance

Operator required: 1

Usage mode: automatic or manual

Processed bars/8h: varies depending on the cycle

POWER SUPPLY and Consumption

Installed power: 5.0 kW

Voltage: 400 V

Minimum pressure: 7 bar

Air consumption: 25 Nl/min

Workable profiles

Usable cutting length: from 325 mm to 5,300 mm (with short system up to 170 mm)

Bevel cuts from -22.30° to +22.30°

Optional features and custom configurations

To meet every production requirement, the SD 26 can be configured with a variety of optional features:

- Bases for extended lengths (4,300 mm and 5,300 mm)

- Rollers for fixed and mobile heads

- 2-outlet vacuum cleaner with bag (model ECO-POL)

- Manual labeler

- Custom templates (single or double cut)

- Intermediate pneumatic support

- Software for cutting long strips and extra-long profiles

- Fly Optimizer for Reusing Bar Remnants

Controls and Integration 4.0

The sliding control panel makes it easy and accessible for the operator to interact with the machine. It supports automatic import of cutting lists via USB or a 100 Mb network, and is designed for integration into Industry 4.0 environments with optimization and monitoring software.

Request a demo or your personalised quote: discover how SD 26 can make every cut more efficient.