SD 26 ALU

Double-head mitre saw for cutting aluminium and PVC profiles

Fast and precise cuts, even for special productions: the versatile saw that optimises every cycle.

Perfect if:

- Are you working with large profiles and looking for a saw that can handle complex cuts?

- You need consistent productivity and precision in variable angle cuts.

- Do you want to reduce errors and speed up production with automated electronic management?

- Are you looking for a rugged and durable machine, suitable for intensive cycles and industrial environments?

- You need to optimise the material using automatic waste management systems.

Request the technical brochure now or speak with an expert.

Fast and precise cuts, even for special productions: the versatile saw that optimises every cycle.

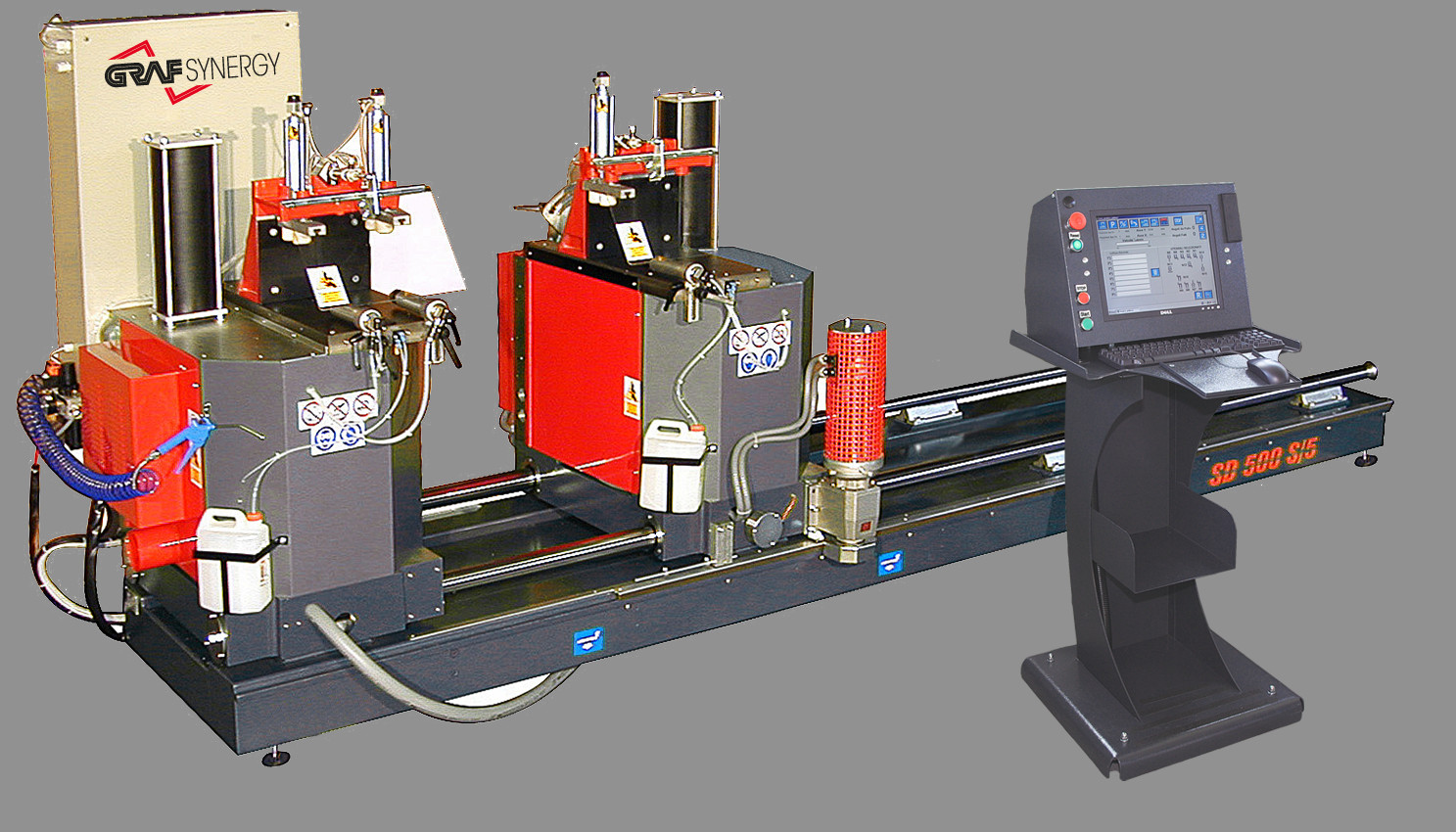

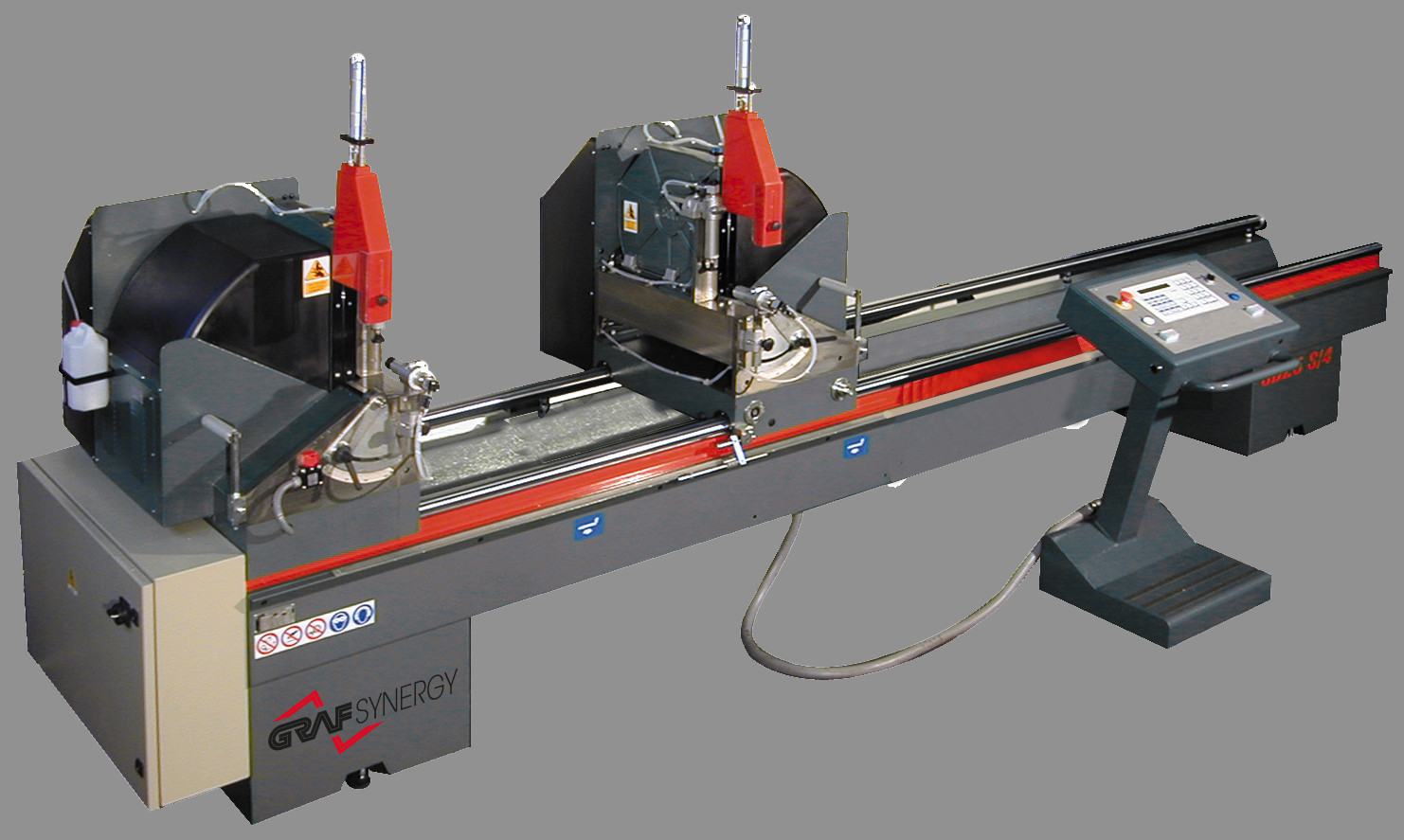

The SD 26 ALU is a dual-head, electronically controlled mitre saw designed for the precise and rapid cutting of aluminium and PVC profiles, even for non-standard applications. Featuring a fixed head and an automatically positioned mobile head, it ensures maximum operational flexibility and reduced cycle times. The front blades with a diameter of 500 mm that retract and the “Short Cut” function allow for processing even within the minimum standard distance between the heads. Robust and reliable, it is designed for production departments seeking precision, adaptability, and consistent performance.

5 Reasons to Choose the SD 26 ALU

- Variable angle cuts without compromise. Angle cuts from -22.30° to +22.30°, with the option to set intermediate angles for maximum production versatility.

- Short cut below the minimum distance. Thanks to the pneumatic stop on the left head, it allows cuts up to 170 mm, optimising even the smallest pieces.

- Robust structure and stable performance. High-strength steel and aluminium frame designed to ensure long-lasting durability and consistent precision over time.

- Maximum workpiece holding. Vertical and horizontal pneumatic vises ensure the stability of the piece during every stage of cutting.

- Automation and intuitive interface. Manage cuts in both automatic mode (with import from management software) and manual mode, using an ergonomic sliding control panel.

Product Details

The SD 26 allows for variable angle cuts, ranging from -22.30° to +22.30°, with manual adjustment for intermediate angles. The two vertical descending blades, retractable, ensure maximum safety and a clean cut. The system is equipped with Venturi effect blade cooling and chip extraction ports with a diameter of 80 mm.

Dimensions

Length: 5,100 mm

Width: 1,200 mm

Height: 2,000 mm

Weight: 950 kg

Performance

Productivity: up to 100 windows per shift*

Operating Mode: Manual / Automatic

Processed bars/8h: variable depending on the cycle

POWER SUPPLY and Consumption

Installed power: 5 kW

Power Supply: 400 V

Air consumption per cycle: 25 Nl/min

Minimum operating pressure: 7 bar

workable profiles

Minimum length: 325 mm (170 mm with ‘Short Cut’)

Maximum length: up to 5,300 mm (depending on the base)

Supported features and processes

- Multiple angle cut

- Short cut for special pieces

- Automated cutting to size

- Scrap optimization using dedicated software

Optional and configurations

The machine can be customised to meet various production needs. Among the available accessories:

- Bases for useful lengths of 4,300 or 5,300 mm

- Rollers (fixed / mobile head)

- ECO-POL vacuum cleaner with 1 bag and dual outlet

- Mechanical stop for pointed cutting

- Manual labeler

- Intermediate pneumatic support

- Custom templates for single or double cuts

- Software for larger teams and profiles

- Fly Optimizer system for automatic waste recovery

TECHNOLOGY AND AUTOMATION

Controlled via a mobile control panel, the SD 26 allows for versatile production management.

- Importing lists from the management system via USB or LAN network

- Cut management manual or automatic

- Integration with Production Optimisation Systems

- Compatible with Industry 4.0 processes

Contact us to find out if SD 26 ALU is the right solution for your production.