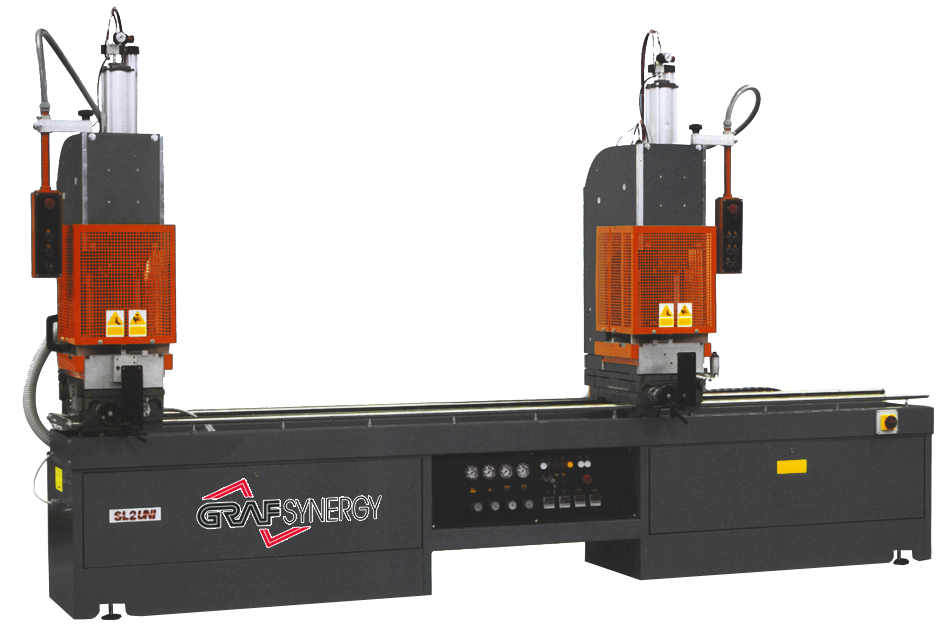

SL2-2

Double-head welder for 90° corners

Compact, precise, and robust: the solution for the simultaneous welding of two corners with calibrated beads

Perfect if…

- Do you want to weld two corners at the same time in a single operation?

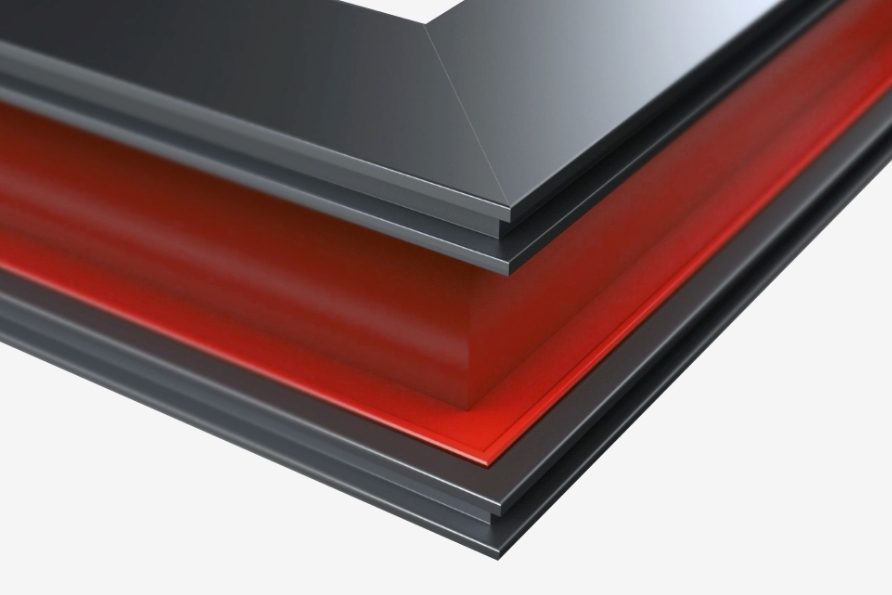

- You work with profiles of various finishes and colors and want to maintain a consistent edge.

- You need a stable and precise machine, suitable for intensive production.

- Are you looking for an easy-to-use system with precise temperature control?

- Do you want to set up your system for Industry 4.0?

Request the technical brochure now or speak with an expert.

Compact, precise, and robust: the solution for simultaneous welding of two corners with a calibrated bead

The SL2-2 is a fixed-angle double-head welding machine designed to create two 90° joints in a single automatic cycle.

The cast iron base and the enlarged support base provide maximum stability and long-lasting durability, even in the most demanding production environments.

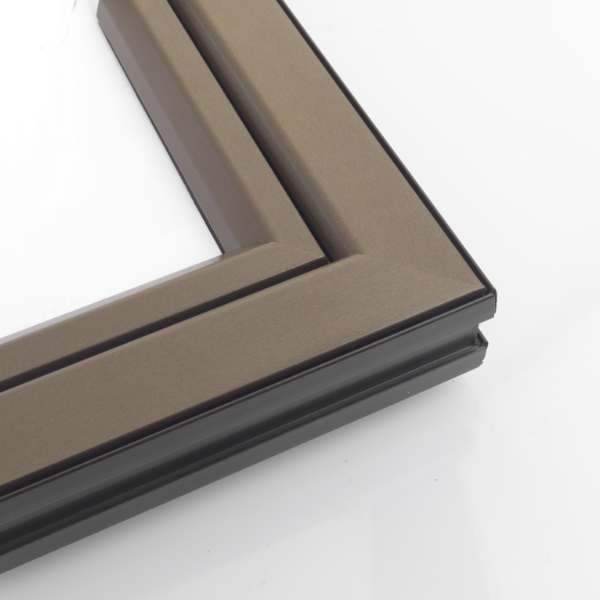

Equipped with a reliable electronic temperature control system and adjustable limit knives ranging from 0.2 to 2 mm, it ensures perfect welds on white, laminated, and coloured profiles.

The contour change is quick and secure, while the user-friendly interface makes it easy to use even for less experienced operators.

5 Reasons to Choose SL2-2

- Guaranteed 0.2 mm calibrated edge. Steel limiters, adjustable from 0.2 to 2 mm for clean welds on any finish.

- Quick Change Template. Fast and precise attachment/detachment system for flexible format management.

- Precise electronic control. Fully automated management of plate and knife temperatures.

- Simplified Interface. Intuitive control and automatic welding cycle: the operator works efficiently and safely.

- Extremely sturdy structure. Cast iron base and reinforced tabletop: uncompromised stability.

Product Details

The welder SL2-2 allows for:

- Welding 90° corners in a single cycle

- Welding of C-shaped elements

The electronic system ensures consistent joint quality, regardless of the type of profile being processed.

Machine dimensions

Length: 3,950 mm

Width: 800 mm

Height: 2,100 mm

Weight: 850 kg

Performance

Operations: manual

Operators required: 1

Maximum weldable frame size: 320 x 2,450 mm

power supply and Consumption

Installed power: 5.7 kW

Voltage: 400 V

Minimum pressure: 7 bar

Air consumption per cycle: 90 Nl/min

Workable profiles

Height: 40 to 200 mm

Width: 40 to 130 mm

Optional features and available configurations

The SL2-2 can be customised with a range of optional features to enhance precision, ergonomics, and process control:

- Additional support arm for profile holders (1 per head)

- Heated knives

- Right head extension (L = 270 mm)

- Internal Seal Press

- Extended base (up to 3,450 mm between the heads)

- Display with integrated Best Weld System

Best Weld System: advanced welding cycle monitoring and anomaly detection.

Technology and automation

The SL2-2 features:

- Electronic temperature control for plates and knives

- Fully automated welding cycle system

- Simplified user interface

- Best Weld System (optional) for quality control and traceability

Preparedness for Industry 4.0.

Want to improve the quality and efficiency of your corner welding? Request the technical brochure or speak with an expert: we will help you set up the SL2-2 to get the most out of your production process.