SL4 FF EVO

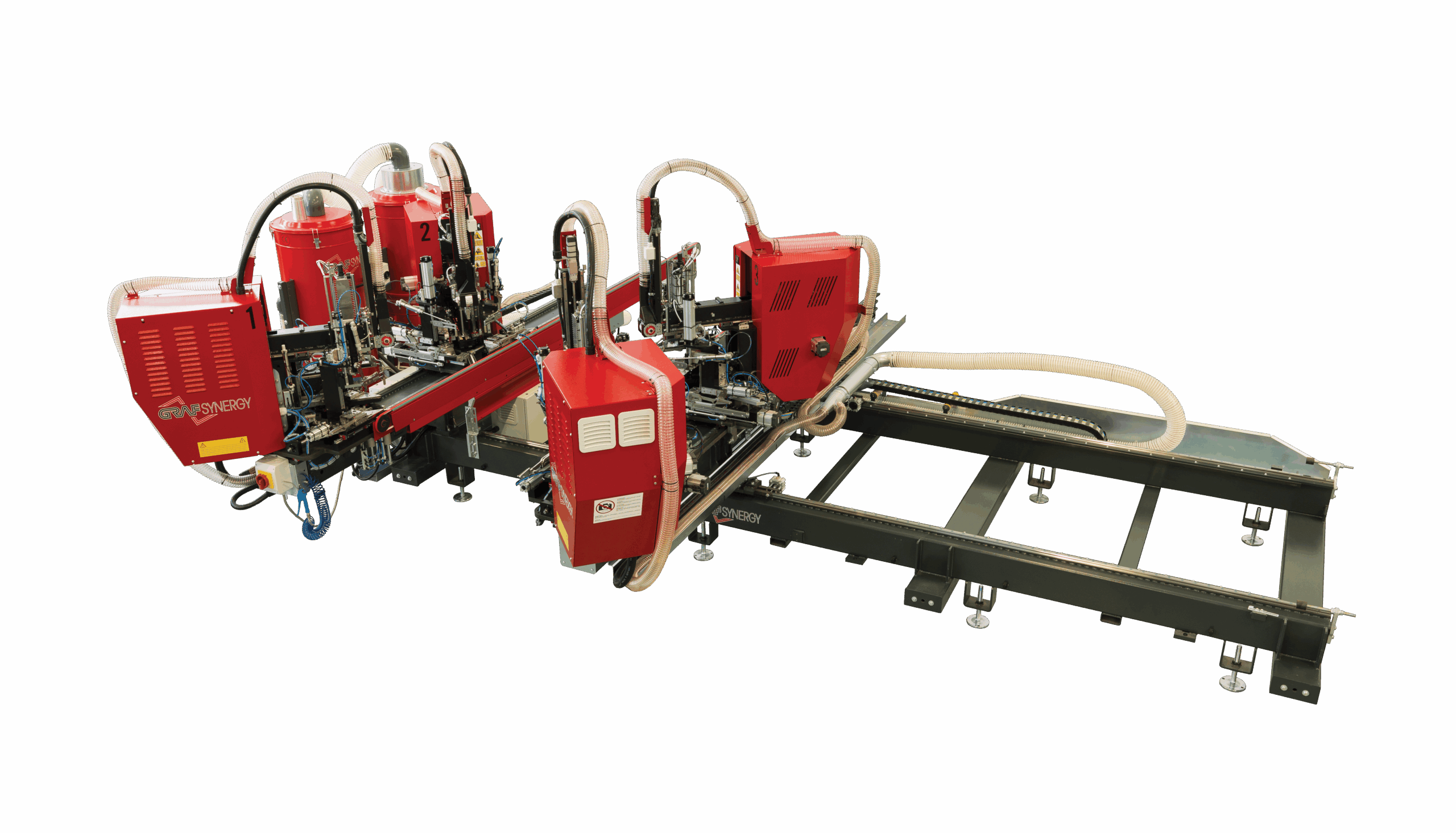

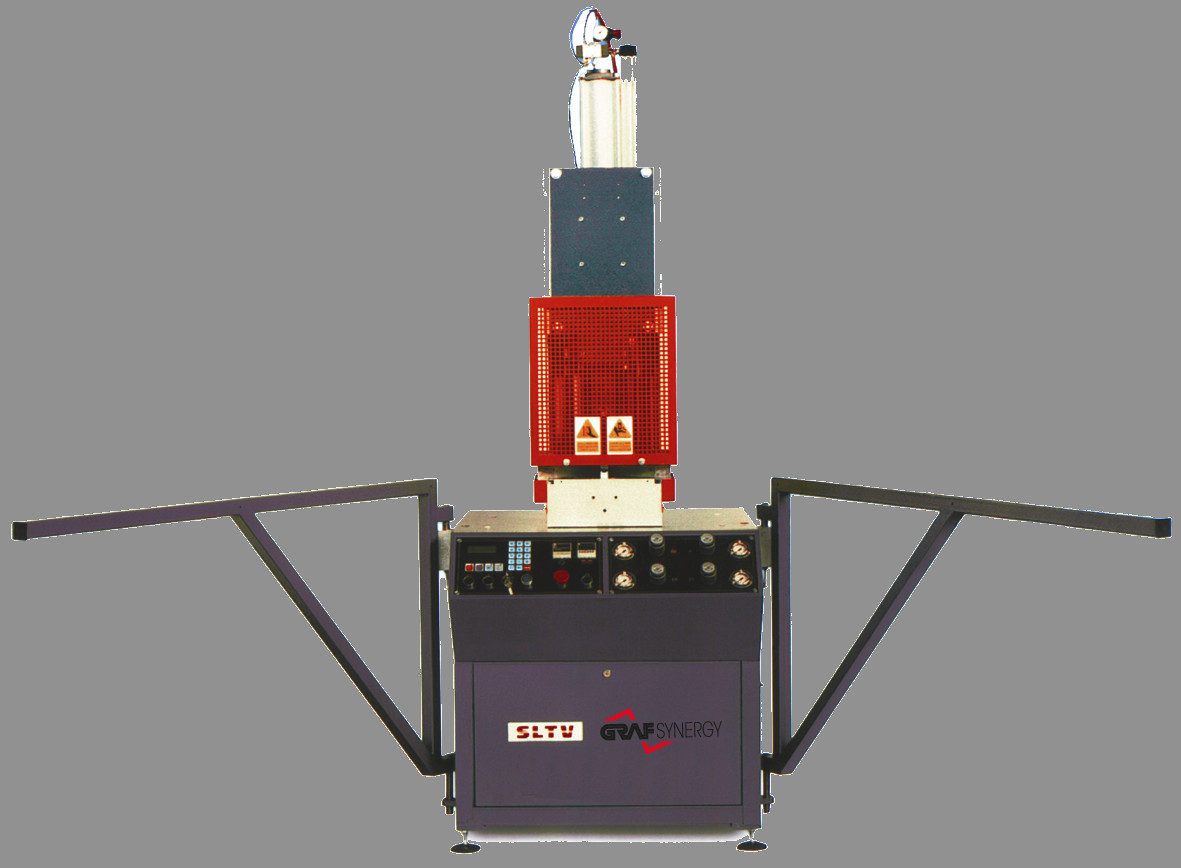

CNC 4-Head Welding Machine for PVC Windows

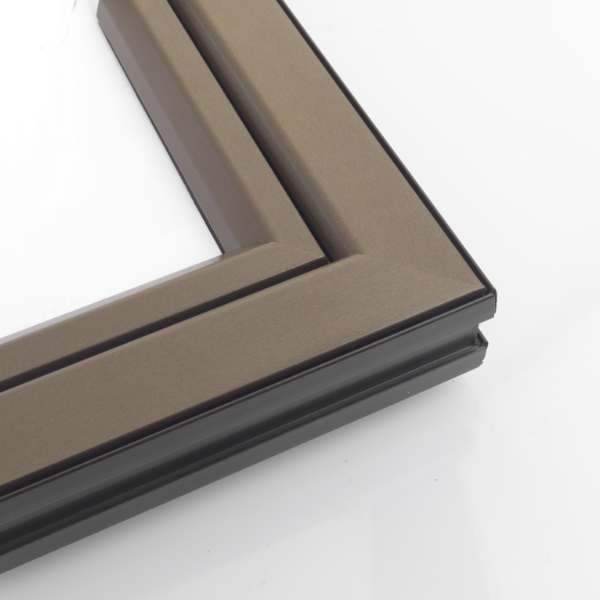

Perfect horizontal welding without a bead, even on complex profiles.

Perfect if you’re looking for:

- Impeccable aesthetics even on complex profiles.

- Complete removal of cleaning and post-welding touch-ups

- Drastic reduction in workforce (only one operator)

- Optimization of production spaces (starting from 25 m²)

- Accurate balance on profiles made of fibre, aluminium, or other non-weldable materials.

- Modular flexibility with electronic control and special configurations

Request the technical brochure now or speak with an expert.

Perfect horizontal welding without a bead, even on complex profiles.

The SL4 FF EVO is the first and only CNC welder with 4 heads capable of completely eliminating the weld seam from the corners of PVC frames.

Thanks to the patented V-Perfect technology, it allows for flat and uniform surfaces without the need for cleaning or touch-ups, even on profiles with non-weldable inserts such as fiberglass or aluminium.

Perfect for companies focused on superior aesthetics, advanced automation, and cost optimisation, the SL4 FF EVO delivers high performance, with a cycle that welds a frame in just 90-150 seconds, processing the seal directly during the operation.

It occupies compact spaces (from 25 m²), works with profiles coated with any type of film or foil, and offers maximum flexibility thanks to customizable configurations.

5 Reasons to Choose SL4 FF EVO

- Perfect finish without rework. The patented V-Perfect technology eliminates the edge: the corners are aesthetically flawless, with no manual touch-ups.

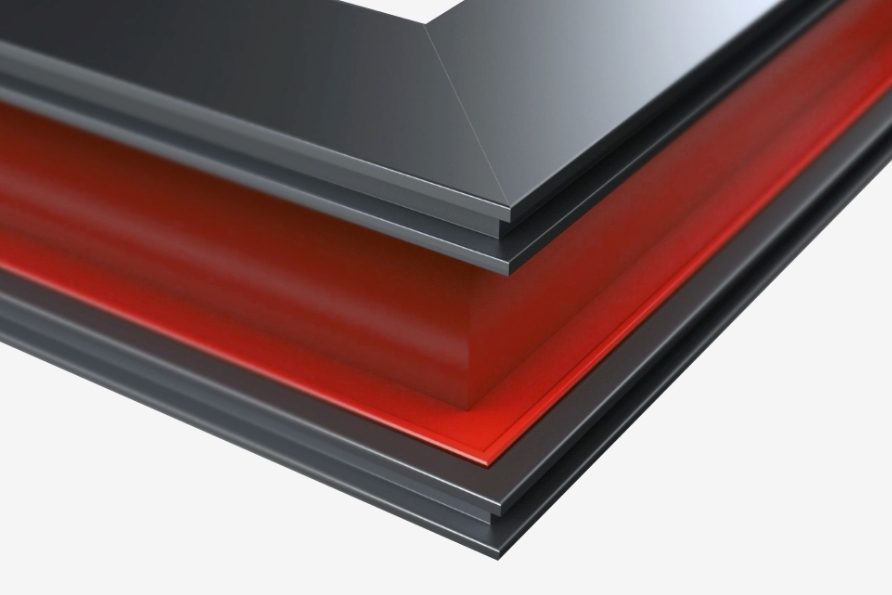

- Every material, every coating. Guaranteed welding even on profiles coated with acrylic films, wood laminates, aluminium, or painted surfaces.

- One operator for the entire cycle. Thanks to complete automation, all stages – milling, melting, compression, and cooling – are carried out automatically.

- Compact and Productive Engineering. Optimised design to occupy just 25 m², with a complete cycle time of 90-150 seconds.

- Automatic Tolerance Correction. An intelligent system calibrates and compensates for angle cutting tolerances (±2 mm) and profile height (up to 0.7 mm).

Product Details

The SL4 FF EVO performs simultaneous horizontal welding of the four corners of the frame, working on the seal directly during the cycle. It integrates a High Speed system for milling, automatic positioning of the counter-profile with magnetic locking, automatic burn adjustment (5 to 6 mm), angular error compensation within ±2 mm, and height correction up to 0.7 mm.

Supported special modes:

U-shaped frame door welding on three sides

C Welding

Sizes

Length: 7,000 to 9,500 mm

Width: 6,000 ÷ 7,000 mm

Height: 2,400 mm

Weight: 3,000 to 5,000 kg (depending on the requested configuration)

Performance

Cycle time: 90-150 sec/frame

Operators required: 1

POWER SUPPLY and Consumption

Installed power: 17 kW

Power Supply: 400 V

Air consumption: 600 Nl/min

Minimum operating pressure: 7 bar.

Workable profiles

Profile height: 35 to 130 mm (optional up to 180 mm)

Profile width: 40 to 130 mm (out of range subject to verification)

Weldable dimensions: min. 300 x 330 mm | max. 3,200 mm (available upon request up to 6,000 mm)

Optional features and custom configurations

The SL4 FF EVO can be configured with:

- Electronic Contour Control System

- Welding maximum height 180 mm

- Cooling table

- Mobile discharge conveyors with lateral movement

- Built-in vacuum cleaner (FF series)

- Data file import conversion software

- Production Data Monitoring (times, changes, unloading)

- Special configurations for welds > 3,200 x 2,800 mm

- UL/CSA Versions

- RS Option – Rapid Speed

- Diagonal Version: welding with the cross member already installed

Advanced technology and automation

Fully controlled by CNC, the SL4 FF EVO integrates optimisation software, an electronic management system for counterforms, and remote monitoring of all parameters. It is fully compatible with Industry 4.0 requirements: enabling real-time quality control, cycle analysis, and remote assistance.

Want to boost productivity without compromising on quality?

Request the complete brochure or a personalised quote now: the Graf Synergy team is ready to assist you in the digital transformation of your production.