SL4-FS

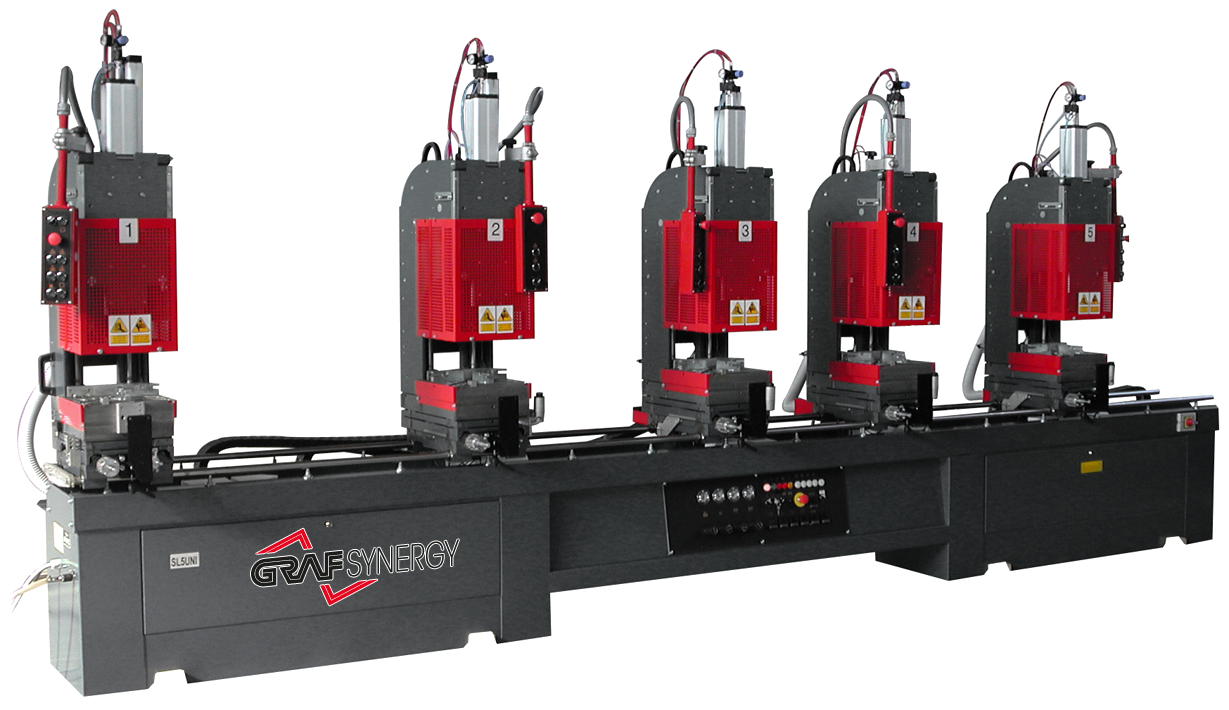

4-Head CNC Welder for PVC Profiles

Extreme speed, consistent quality, guaranteed productivity

Perfect if you want:

- Increase productivity to 480 units per shift without compromising on quality.

- Welding 4 corners simultaneously with electronic compensation for deviations.

- Manage complex or non-standard profiles with absolute precision.

- Fully automate the welding cycle while reducing operator workload.

- Integrate the inline welder with the cleaners for a continuous flow.

Request the technical brochure now or speak with an expert.

Extreme speed, consistent quality, guaranteed productivity

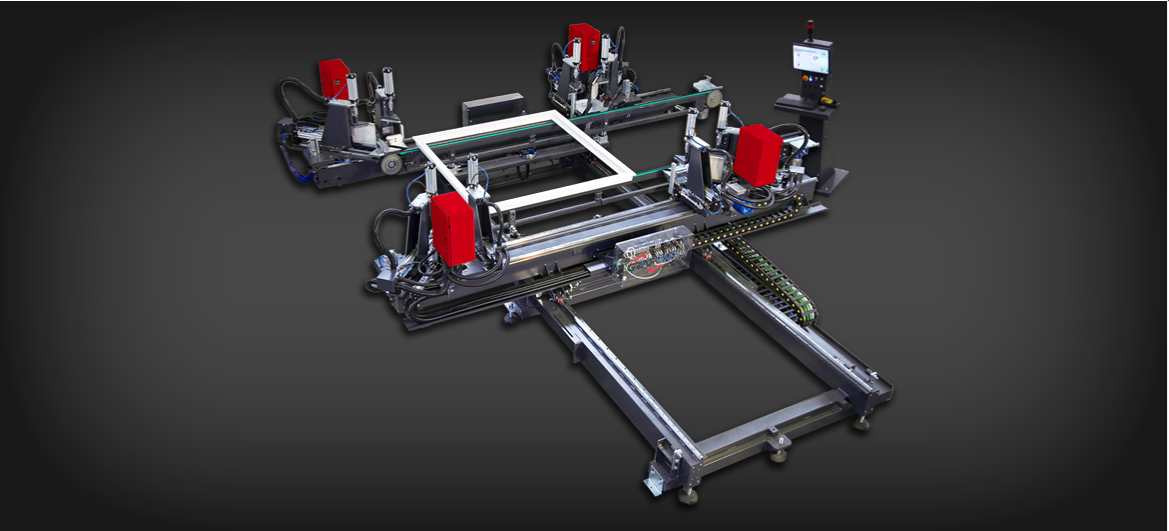

The SL4-FS is a CNC welding machine with 4 heads and 7 controlled axes, designed to join all four corners of a PVC frame in a single cycle, achieving a speed that is 50% faster than traditional systems.

Each stage – positioning, melting, compression, and cooling – is managed automatically, ensuring consistent and repeatable quality over time.

Thanks to its reinforced structure, parallel welding system with automatic deviation correction, and software developed by the R&S GRAF Synergy lab, the SL4-FS represents the ultimate solution for companies aiming for production excellence and full integration into Industry 4.0 frameworks.

5 Reasons to Choose SL4-FS

- +50% productivity in 8 hours. High-speed welding thanks to 7 CNC axes and movement on linear guides and racks.

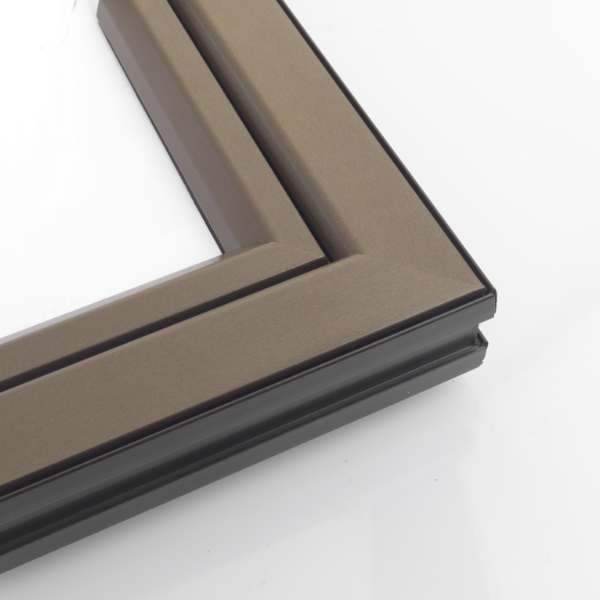

- Custom curb with automatic adjustment. Intelligent adjustment system from 0.2 to 2 mm based on the profile, ensuring optimal welding every time.

- Automatic Corner Correction. The parallel welding corrects dimensional deviations on all four sides, ensuring perfectly square frames every time.

- Intuitive Interface and Barcode Scanning. User-friendly software with preset parameters and guided menus: simple and fast management.

- Electronic Temperature Control. Each profile code is linked to specific thermal parameters to prevent burns and defects.

Product Details

The SL4-FS performs simultaneous horizontal welding of all four corners in a fully automated manner. Each cycle includes digital positioning, thermal control welding, and the release of the frame onto a conveyor, ready for cleaning.

Sizes

Length: 5,250 mm

Width: 2,200 mm

Height: 1,650 mm

Weight: 3.000 kg

Performance

Productivity: up to 480 square feet/8 hours*

Operators required: 1

* (indicative value, depends on profile, curb, and loading system)

POWER SUPPLY and Consumption

Installed power: 16 kW

Power Supply: 400 V

Minimum pressure: 7 bar

Air consumption per cycle: 100 Nl/min

Workable profiles

- Profile height: 40 to 180 mm

- Profile width: 40 to 130 mm

- Weldable frame dimensions: minimum 370×400 mm – maximum 3,200×2,800 mm

Supported features and processes

Main processes:

- Automated cycle positioning and management

- Simultaneous welding of 4 corners

- C-welds

Optional features and custom configurations

The SL4-FS can be equipped with various options for a customised configuration:

- Direct connection with GRAF Synergy cleaners

- Welding kit with three sides, with or without threshold support.

- Brushless motors for greater precision

- Energy Saver for reducing consumption

- Cooling table

Technology and automation

The 7-axis CNC handling system with magnetic reading ensures absolute precision. The GRAF software allows for advanced parameter management, featuring barcode reading, presets for each profile, and remote diagnostics.

The SL4-FS is compatible with Industry 4.0 standards and ready for full integration into management systems.

Want to transform your welding process?

Request the complete brochure now or book a consultation with our technicians. SL4-FS is the professional choice for those seeking performance, efficiency, and quality.