SL4-U

CNC 4-Head Welder for PVC Profiles

Maximum precision in all four corners, fully automatic cycle, quality guaranteed over time

Perfect if…

- Do you want to eliminate dimensional errors in welded frames?

- Are you looking for a 4-head welder with quick contour change?

- You need to fully automate the welding process.

- Do you want a machine ready for Industry 4.0?

- You need to produce up to 240 frames per shift with just one operator.

- You work with different profiles and want automatic temperature control.

Request the technical brochure now or speak with an expert.

Maximum precision in all four corners, fully automatic cycle, quality guaranteed over time.

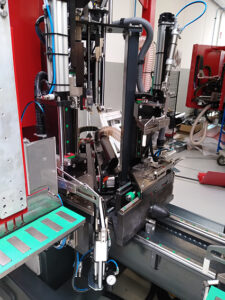

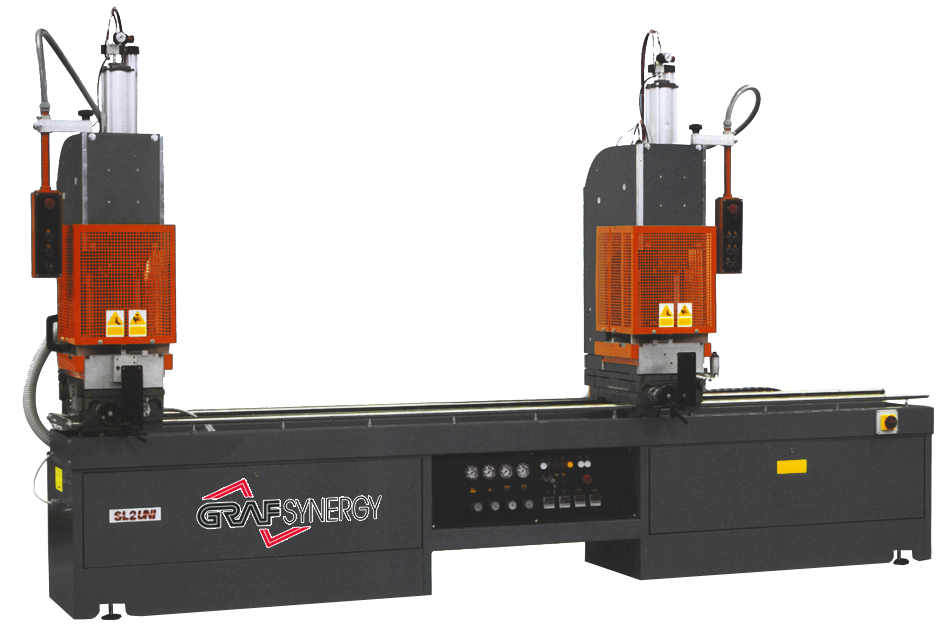

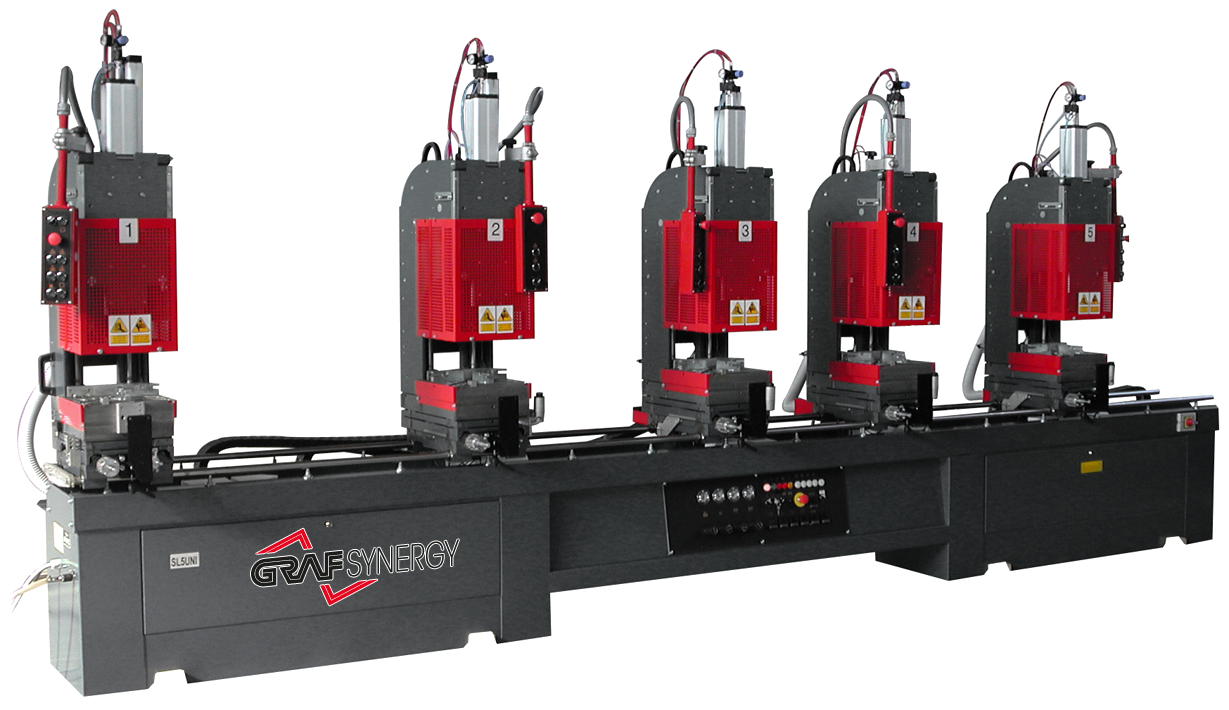

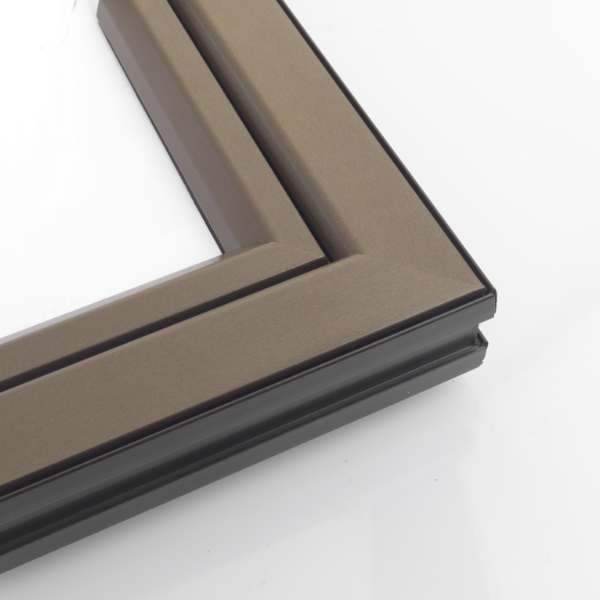

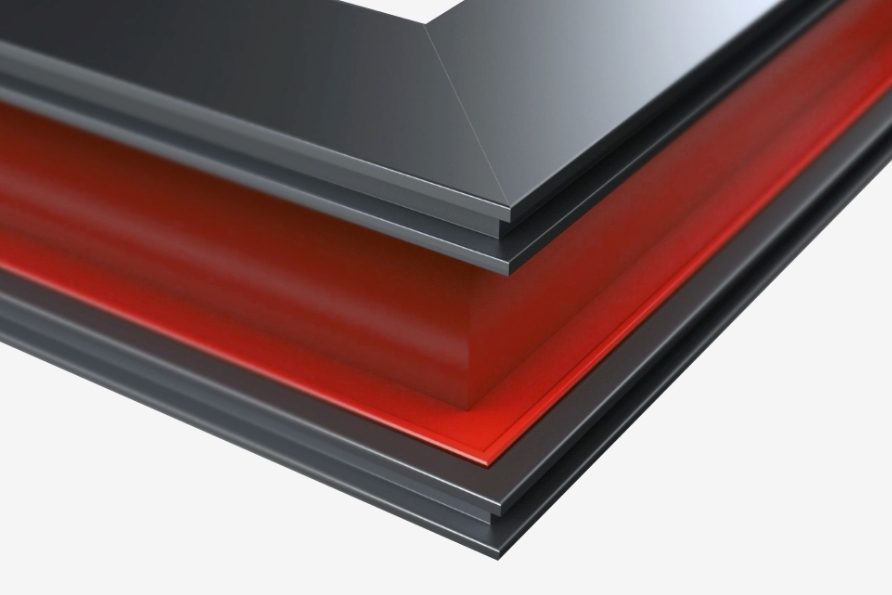

The SL4-U is a CNC welder with 4 heads and 3 controlled axes, designed for the horizontal and simultaneous welding of the four corners of a PVC frame.

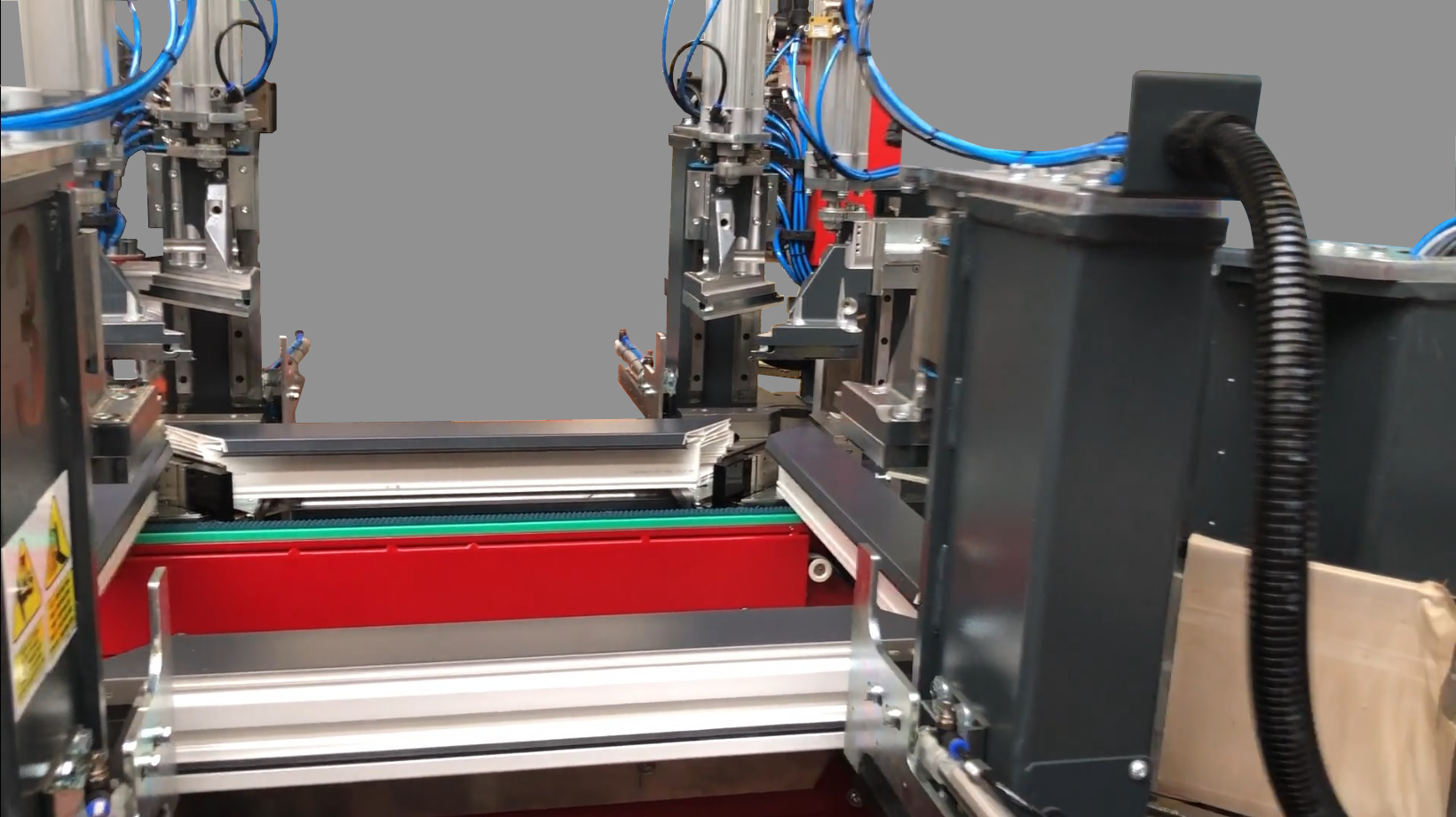

Every stage – from positioning to welding quotas, to the melting, compression, and cooling cycles – is managed automatically, and at the end of the cycle, the frame is released onto conveyor belts leading to the cleaning area.

Equipped with a high-precision handling system on linear guides and racks with digital magnetic reading, the SL4-U ensures smooth and accurate positioning of the heads.

The specific arrangement of the profile loading references allows for the automatic distribution of cutting deviations across all four corners, effectively addressing the issue of final measurement errors.

An ideal solution for window manufacturers seeking reliability, consistent quality, and reduced waste.

5 Reasons to Choose SL4-U

- Guaranteed dimensional accuracy. Automatically distributes cutting deviations across all corners, maintaining the nominal measurements of the frame.

- Smooth and Controlled Movement. The axes move along linear guides with rack and pinion systems and magnetic reading, ensuring stability even during intensive cycles.

- Optimised welding for every profile. The electronic temperature control adjusts to the profile code, ensuring consistency and quality.

- Quick Change of Templates. Fast and precise attachment/detachment system, no tools required: significantly reduced downtime.

- Total automation and ease of use. Data acquisition via USB or TCP-IP, automatically adjustable burning (5÷6 mm), and an intuitive interface.

Product Details

The SL4-U allows for horizontal and simultaneous welding of the four corners of a PVC frame, ensuring geometrically perfect joints. It also supports “C” welds for special configurations. Each phase—from positioning to welding—is managed automatically, reducing intervention times and increasing overall reliability.

Machine dimensions

Length: 5,250 mm

Width: 2,200 mm

Height: 1,650 mm

Weight: 2.500 kg

Performance

Productivity: up to 240 square meters / 8 hours*

Operators required: 1

* Variable data based on profiles, curb, and loading speed

POWER SUPPLY and Consumption

Installed power: 12 kW

Voltage: 400 V

Air consumption: 180 Nl/min

Minimum operating pressure: 7 bar

Workable profiles

- Profile height: 40 to 180 mm

- Profile Width: 40 ÷ 130 mm

- Weldable frame sizes: min. 400 x 400 mm | max. 3,200 x 2,800 mm

Optional features and custom configurations

The SL4-U is customizable with numerous options to meet every production need:

- Welding kit on 3 sides (with or without threshold support)

- Parallel welding kit

- Cooling table

- Exit profile tapes

- Steel or coated/heated knife set

- Automatic transmission kit with a cord thickness of 0.2 to 2 mm (depending on the geometry and colour of the profile)

- Radio CCD barcode scanner

- Brushless motors on the axles

- Energy Saver option and automatic temperature adjustment

- Premade lift-and-slide seals with feet

Possibility of online connection with Graf Synergy cleaners

Technology and automation

The SL4-U integrates a CNC system with 3 controlled axes and advanced electronic management of welding parameters. The interface is designed to be simple and user-friendly, featuring data connection via USB or TCP-IP and the ability to directly import welding lists.

It is fully compatible with Industry 4.0 requirements, designed for IoT connectivity, remote control, and real-time monitoring of production parameters.

Ready to take your business to the next level? Download the brochure, request a quote, or book a personalised demo: the Graf Synergy team is ready to show you how SL4-U can transform your production.