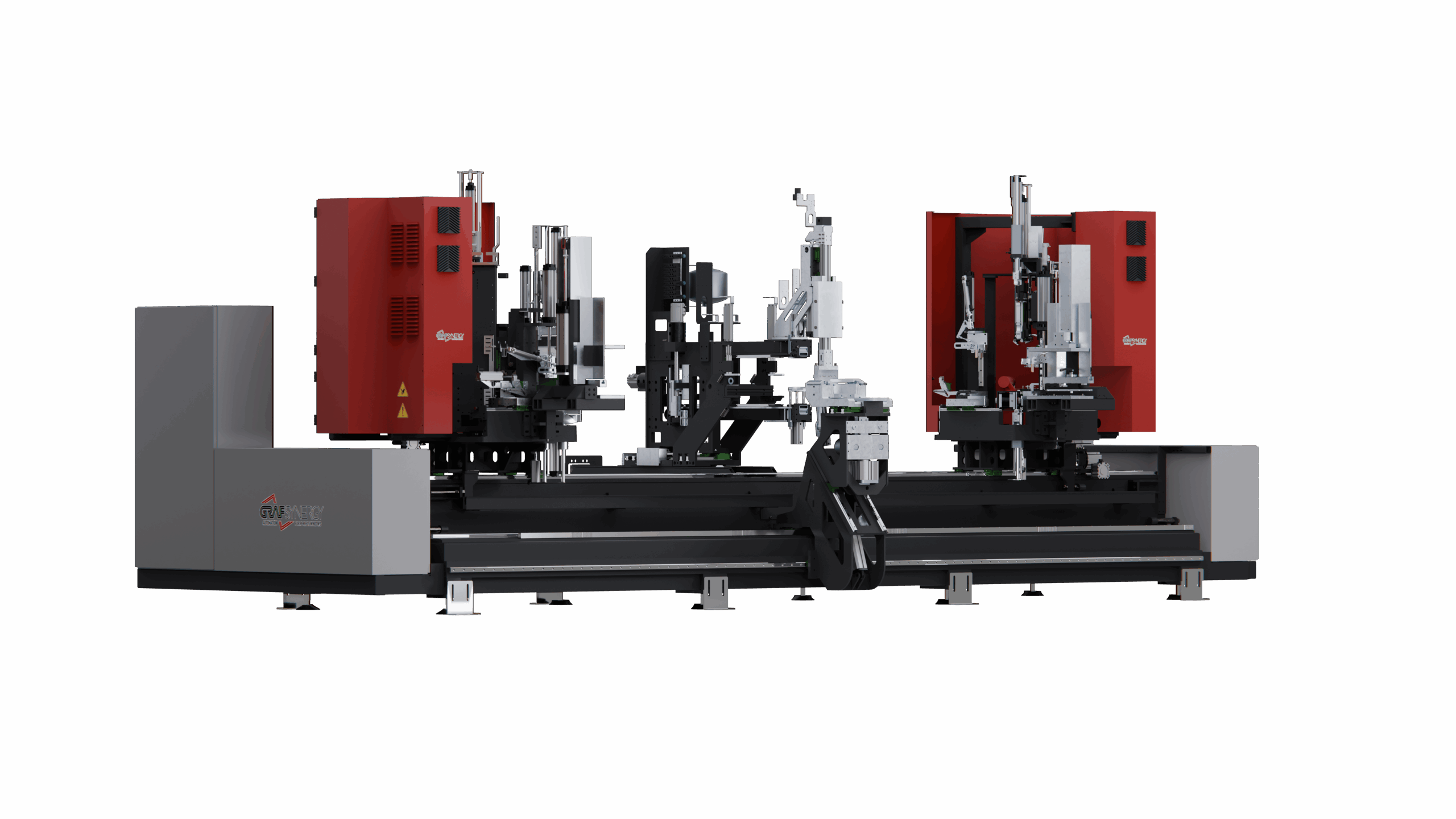

SL5FF TV

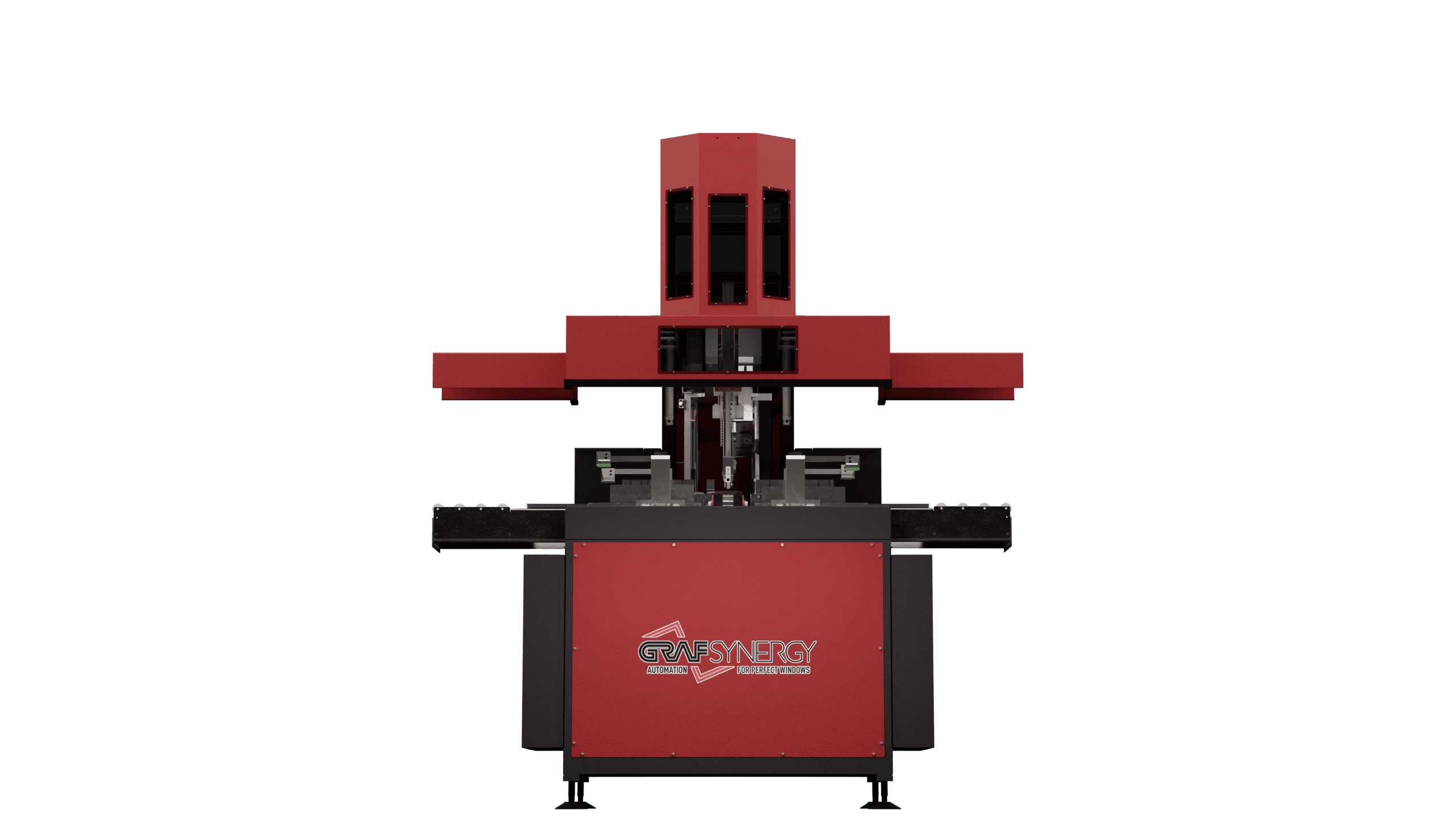

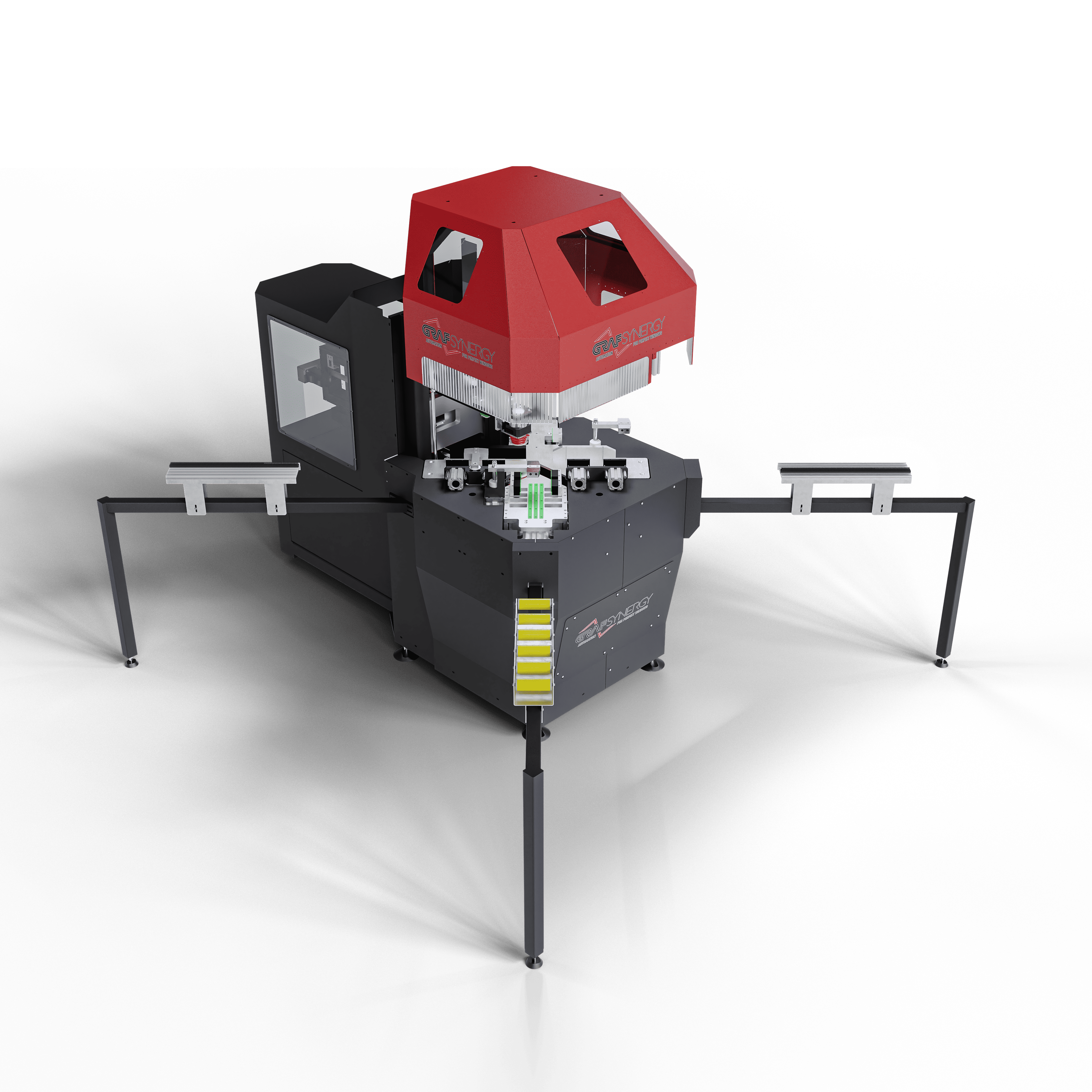

5-Head Inline CNC Welder for V-Shaped Welded Cross Members

A comprehensive production centre for perfect welds in a single cycle

Perfect if:

- Produce frames with V-welded cross members and want to reduce cycle times.

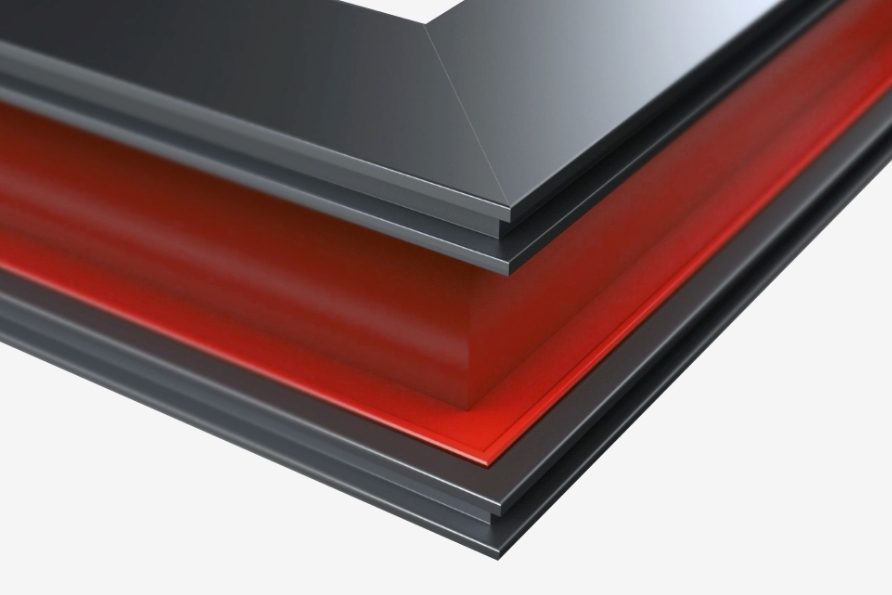

- You work with painted, laminated, or coated profiles that cannot tolerate reworking.

- You need a complete system that combines power, precision, and automation.

- Are you looking for a machine that automates every stage of the process, from milling to welding?

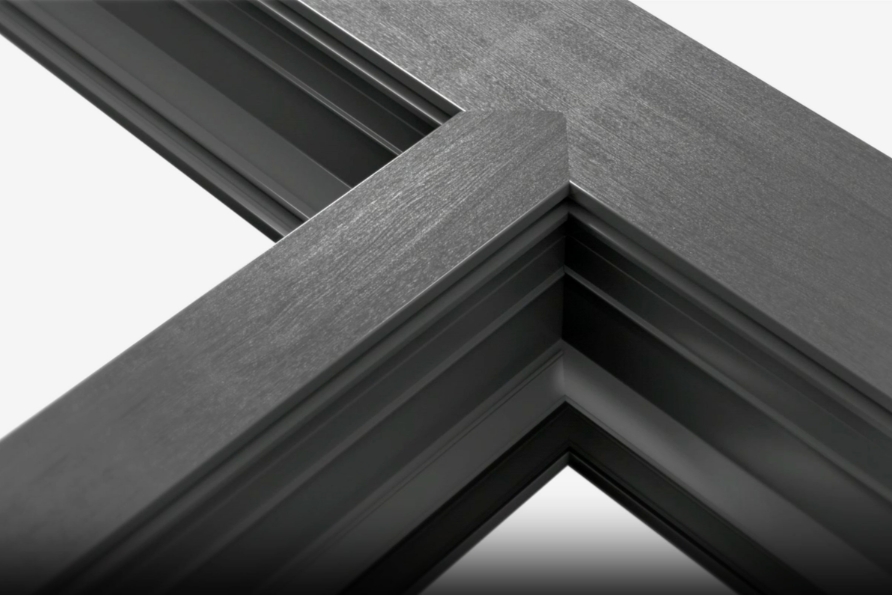

- Do you want to achieve perfect corners and joints, even with cutting errors or profile tolerances?

- You work in an industrial setting and want to integrate production data control.

Request the technical brochure now or speak with an expert.

A comprehensive production centre for perfect welds in a single cycle

The SL5FF TV is much more than just a welding machine; it is an advanced CNC system designed to create complete frames in a single operation. Equipped with 5 inline heads, it allows for the simultaneous welding of 2 outer corners and up to 3 internal cross members, even in Notch Transom Welding mode. Thanks to the V-Perfect technology, it completely eliminates the weld seam, ensuring a flawless aesthetic finish without the need for cleaning or reworking. The system is designed for high-volume production with top-notch aesthetic quality and maximum productivity, making it ideal for the most demanding markets.

5 Reasons to Choose the SL5FF TV

- Complete welding in a single cycle. Simultaneous welding of internal corners and cross members (up to 3): a full cycle in just 180 seconds.

- Perfect aesthetics on every material. V-Perfect technology for invisible welds even on acrylic profiles, aluminium, wood, or painted PVC.

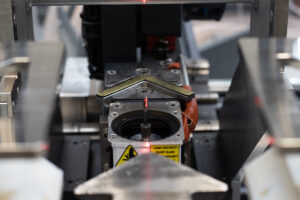

- Maximum automation, less labour. Every stage is managed electronically: High Speed milling, melting, compression, and cooling.

- Automatic Cutting Error Correction. It compensates for errors of up to 2 mm (corners) and 0.5 mm (profile height), always ensuring the final quality.

- Intelligent production control system. Monitoring of times, cycles, and welding data to enhance performance and predictive maintenance.

Product Details

Designed for high-intensity productions, the SL5FF TV performs every operation necessary to create a complete frame with precision and speed. Each CNC head works in synergy to achieve aesthetically pleasing and structurally perfect joints.

Sizes

Length: 3,600 mm

Width: 7,000 mm

Height: 2,500 mm

Weight: 6.250 kg

Performance

1 cycle every 180 seconds (variable)

Simultaneous welding: 2 corners + up to 3 cross members

Minimum workable size: 1,050 × 750 mm (with standard profile L 70 mm)

Maximum weldable side: 3,200 mm

Operators needed: 1

POWER SUPPLY and Consumption

Installed power: 25 kW

Voltage: 400 V

Air consumption per cycle: 600 NI/min

Operating pressure: 7 bar

Weldable profiles

Profile height: 60 to 82 mm

Profile Width: 60 to 110 mm

Supported features and processes

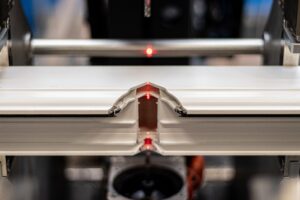

- Welding external corners at a 45° angle (V-Perfect mode)

- Internal cross member welding using Notch Transom Welding method

- Integrated gasket processing within the cycle

- Automatic compensation for cutting errors and tolerance

Optional and configurations

To meet every production requirement, the SL5FF TV can be equipped with:

- Cordless Welding Fume Extractor

- Data file import and conversion software

- Electronic Control of Counter Profiles

- Production Data Monitoring System (cycle times, template changeovers, etc.)

Technology and Automation

The heart of the SL5FF TV is an advanced electronic system that controls every aspect of the process: from burn adjustment (5 to 6 mm) to fast milling, and even intelligent tolerance management. It can all be integrated into Industry 4.0 environments.

- Fully Automated Cycle

- Magnetic positioning upper counter-support

- Compatible with Industry 4.0 (upon request)

- Dynamic electronic regulation

- Integrated V-Perfect Technology

Contact us to find out if the SL5FF TV is the right solution for your production.