SLV

Single-head variable angle welder for special PVC and aluminium profiles

The ideal solution for complex welding: maximum flexibility, guaranteed precision.

Perfect if…

- You create out-of-square frames or irregular shapes.

- You need to weld large profiles (up to 300 mm in width).

- Are you looking for a sturdy and precise machine that can handle small batches?

- Do you want to avoid reworking on complex joints?

- I frequently change measurements and angles.

Request the technical brochure now or speak with an expert.

The ideal solution for complex welding: maximum flexibility, guaranteed precision.

SLV is the single-head variable angle welder designed to accurately handle any type of out-of-sqaure welding, from 30° to 180°, even on large profiles.

Ideal for window fitters and special departments, it is constructed from steel and cast iron to ensure maximum stability even when working with large profiles.

Thanks to the integrated electronic system, SLV allows for quick angle adjustments, constant monitoring of welding times and temperatures, and optimises performance even for small batches or customised productions.

Each cycle is automated, and the interface guides the operator in case of any anomalies, ensuring continuity and quality of the process.

5 reasons to choose SLV

- Millimetre-precision even off-square. Accurate welds from 30° to 180° thanks to electronic parameter control and stable angle retention.

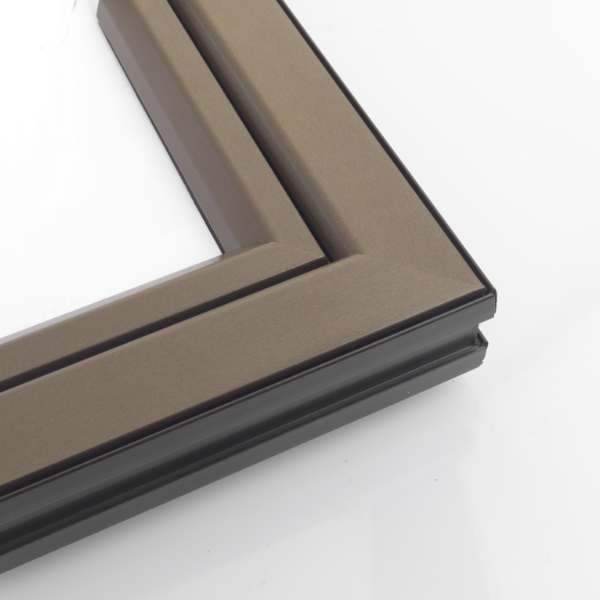

- Designed for special and oversized profiles. Handles profiles up to 200 x 200 mm at 90° and 300 mm wide at 180°: perfect for complex orders.

- Intelligent Process Control. The electronic system measures real-time welding times, alerts for anomalies, and guides the operator when necessary.

- Solid and Reliable Structure. The base made of cast iron and components in steel/aluminium ensure stability, durability, and consistent results.

- Quick Template Change. A fast template replacement system designed to reduce machine downtime.

Product Details

SLV enables high-precision welding on angles from 30° to 180°, making it possible to create special fittings, non-standard shapes, and out-of-square joints. The cast iron structure ensures stable support even for heavy profiles, preventing bending and loss of precision.

Machine dimensions

Length: 1,250 mm

Width: 920 mm

Height: 2,300 mm

Weight: 270 kg

Operational Performance

Operators needed: 1

Operating mode: Manual

Automated cycle: Yes

POWER SUPPLY and Consumption

Installed power: 3.4 kW

Power Supply: 230 V single-phase

Air consumption: 45 Nl/min

Minimum operating pressure: 7 bar

Workable profiles

- Profile height: 40 to 200 mm

- Profile Width:

- 40 ÷ 200 mm (at 90°)

- 40 ÷ 300 mm (at 180°)

Supported features and processes

Main Processes:

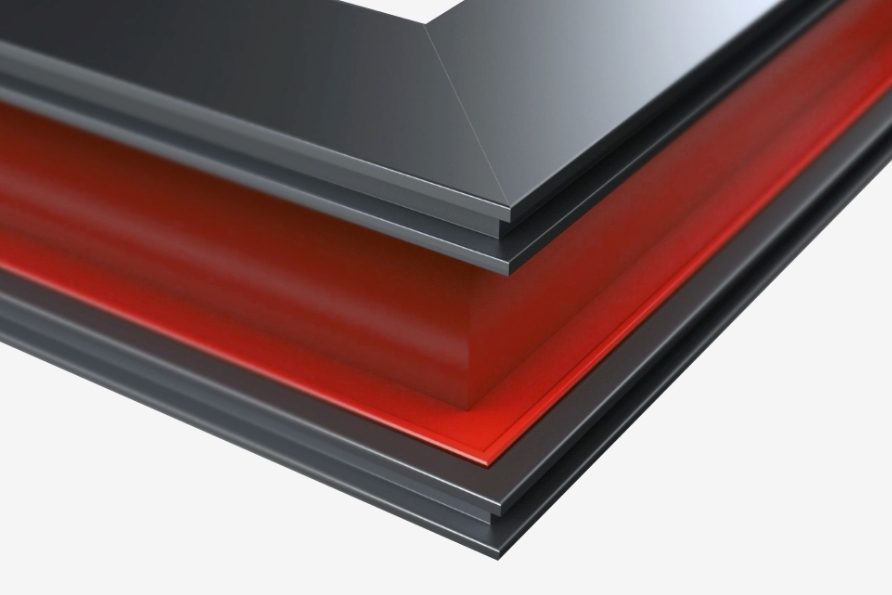

- Variable angle welds ranging from 30° to 180°

- Management of large section profiles

- Custom window and door manufacturing based on design

Optional features and custom configurations

SLV can be customized with:

- Custom-shaped templates

- Horizontal/vertical Morse right-left for optimal piece fastening

These options allow for the perfect customization of the machine for special order productions.

Technology and automation

The advanced electronic system of the SLV ensures:

- Automatic Welding Parameter Management

- Active monitoring of timelines and errors

- Intuitive Operator Interface

Compatible with Industry 4.0 principles, SLV can be integrated into systems for traceability, remote diagnostics, and centralised production management.

Want to know how SLV can help you create custom fittings? Download the complete brochure now or request a personalised consultation with an expert from Graf Synergy.