ST1 A

Automatic Corner Milling Machine for Door Frame Exchange

Precise and repetitive automation for corner finishing of post-weld doors

Perfect if…

- You need to refine the internal corners of the welded doors without relying on skilled operators.

- Are you looking for an automated solution to enhance accuracy?

- Do you want to minimise manual rework?

- We produce medium to large batches of fixtures and ensure consistent quality.

- Do you already have an SL4-FF Evo welder and want to enhance its efficiency?

- Do you have limited space for a dedicated station for…

Request the technical brochure now or speak with an expert

Precise and repetitive automation for post-welding door edge finishing

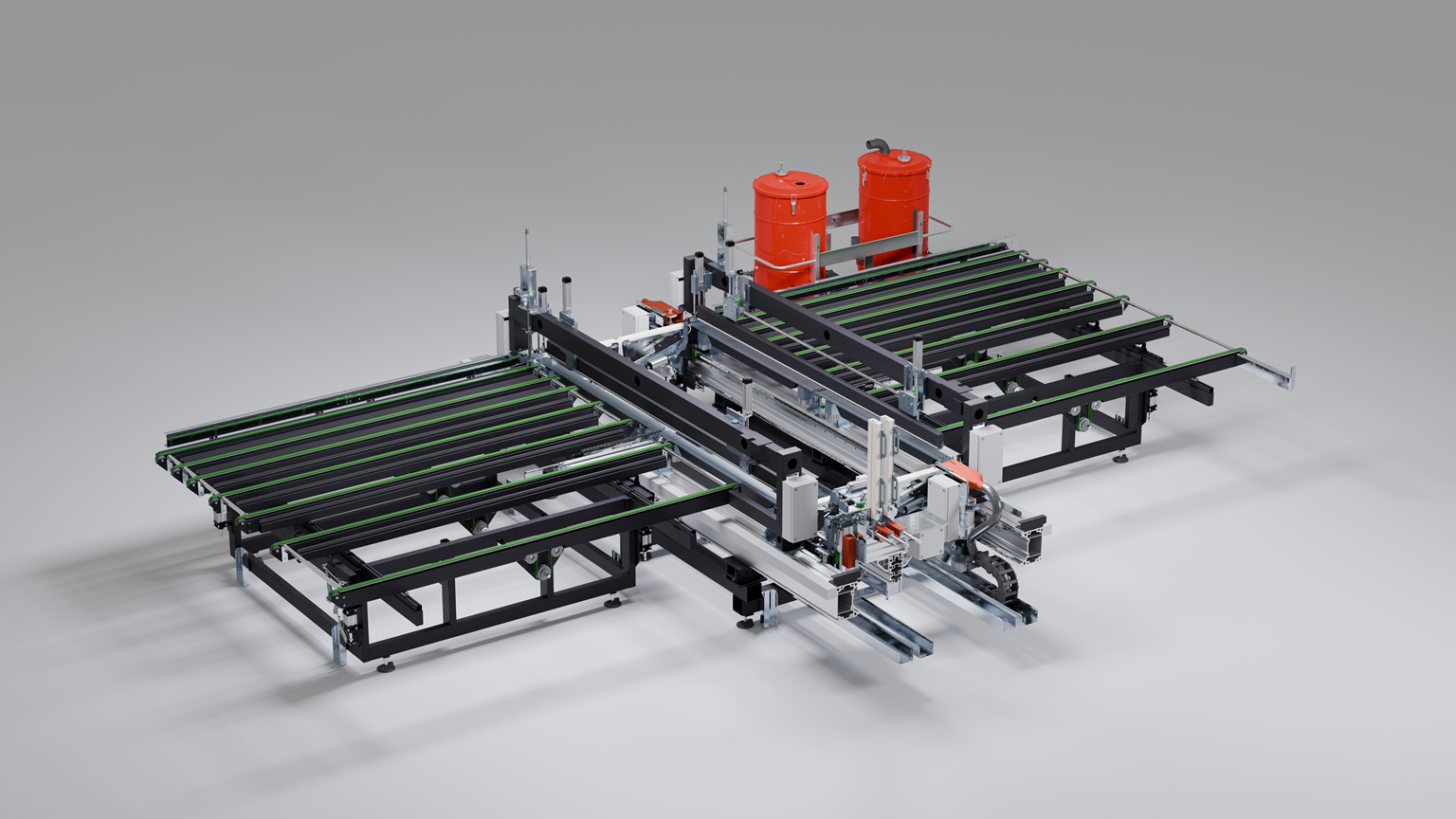

Designed to automate the milling of internal corners resulting from the welding of three profiles with a reduced profile, ST1 A is the ideal milling machine for those looking to eliminate manual processes, increase precision, and seamlessly integrate into a production line.

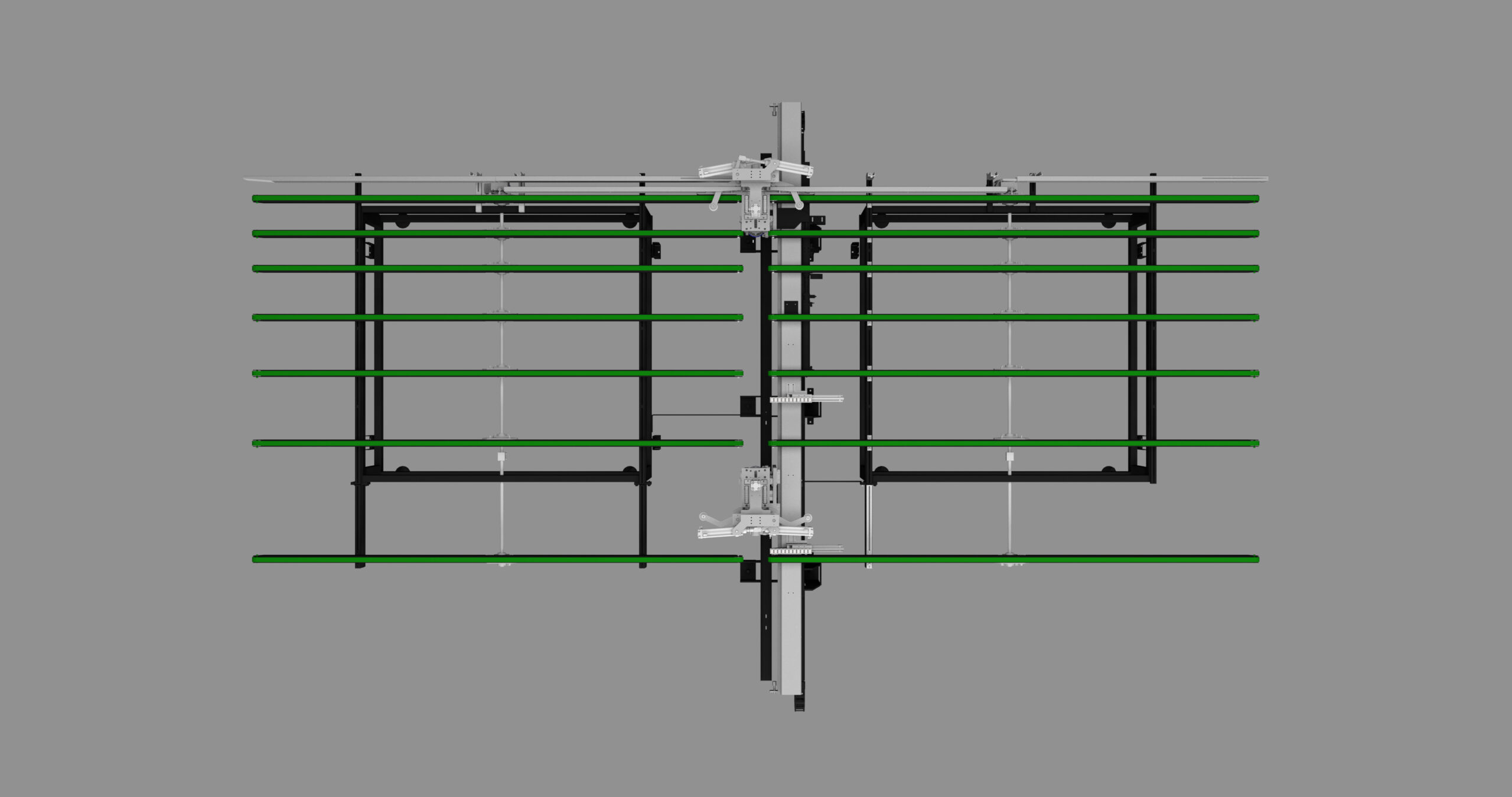

Equipped with a double-length automatic bench and a high-speed central milling unit, this machine ensures perfectly centred and consistent machining, thanks to the automatic measurement of the reference plane.

Compatible with the SL4-FF Evo welder, it can replace the cooling table, simplifying line management. The integrated control allows the milling machine to be operated directly from the welder’s control panel.

5 Reasons to Choose ST1 A

- Complete Automation of Corner Milling. Fully automated management of gripping, centering, and milling of the two corners in sequence, without the need for manual intervention.

- High repeatability precision. Thanks to the automatic measurement of the reference plane, each milling is calibrated to the millimetre on every type of profile.

- Smart integration with the SL4-FF Evo welder. Direct control from the welder’s panel and the option to replace its cooling table.

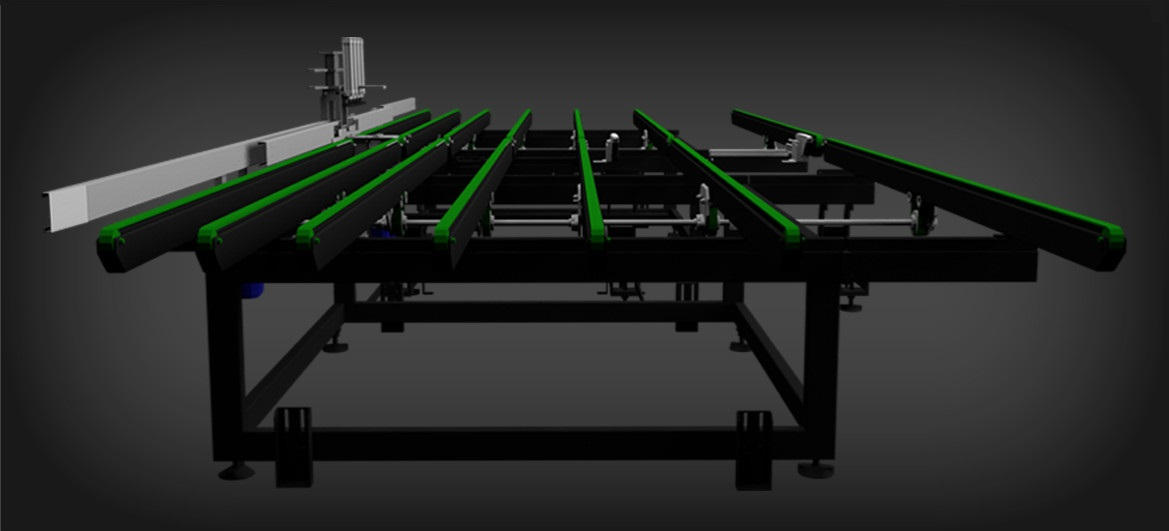

- Sturdy structure and optimized footprint. Spacious 8×4.5 metre workbench with scratch-resistant transport, perfect for delicate profiles.

- Ideal for high-volume production. One operator, continuous operation, reliability, and reduced rework: perfect for intensive lines.

Product Details

ST1 A is designed to automatically and accurately perform the milling of excess material that forms in the two internal corners of the welded panels.

Sizes

Length: 8,000 mm

Width: 4,500 mm

Height: 1,800 mm

Weight: 1.200 kg

Performance

Operation: automatic cycle manual

Required Operators: 1

Maximum Work Area: 3,200 x 3,200 mm

Minimum workable frame: 400 x 400 mm

POWER SUPPLY and Consumption

Installed power: 2.5 kW

Power Supply Voltage: 400 V

Operating pressure: 6-8 bar

Air consumption: 10 Nl/min

Workable profiles

Compatible with welded PVC frame profiles

Specification for milling corners with reduced door after welding

Supported features and processes

Thanks to pneumatic jaws, a transport system with scratch-resistant coating, and a high-speed central milling unit, it ensures consistent and repeatable processing across all batches.

Supported Processes:

- Milling of internal corners after welding

- Automatic centering of the piece

- Automatic leveling and compensation of the plane

Optional and configurations

The ST1 A is provided in a standard version without any optional features, but the range includes a version called ST2 A, which can be equipped with two milling heads for even higher productivity.

This advanced setup is recommended for high-turnover lines or for those looking to further reduce the operational cycle per window.

Technology and automation

The control system of the ST1 A is designed to integrate with Industry 4.0 systems, enabling remote control and interfacing with the SL4-FF Evo welder.

The management software allows for:

- Remote activation and monitoring via SL4 panel

- Automatic calibration of milling coordinates

- Compatibility with industrial interconnection protocols

Do you want to boost your productivity with ST1 A?

Discover how this milling machine can transform your production process.

Download the full brochure or request a personalised quote: our experts are available to advise you on the best configuration for your line.