TAV BIP

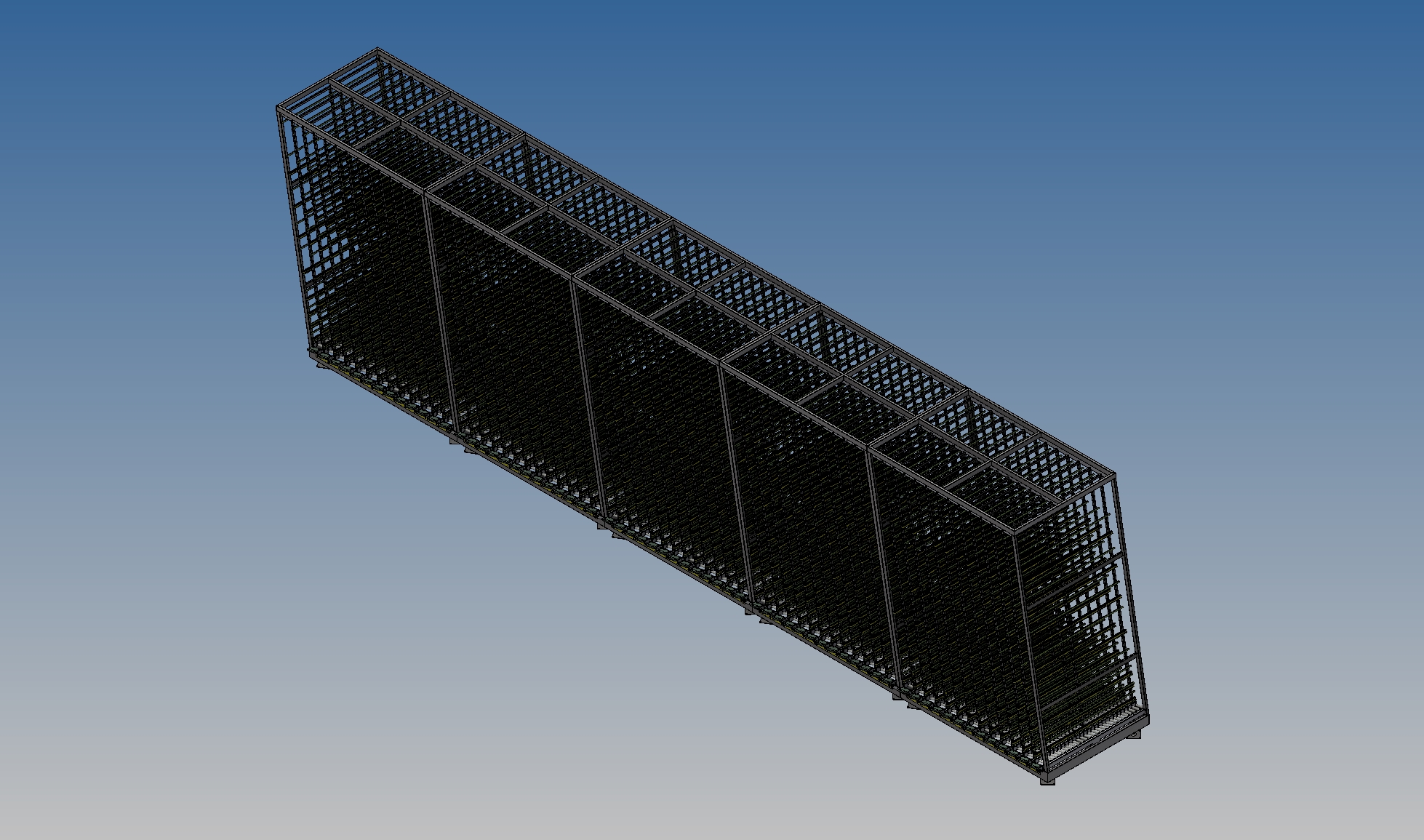

Horizontal Two-Tier Table for Post-Welding Logistics

Smart logistics for high productivity lines

Perfect if:

- Optimise the organisation of post-welding assembly stations

- Manage multiple flows from different welding lines simultaneously.

- Reduce downtime and improve workplace ergonomics.

- Automate the transport of paintings from one stage to another.

- Integrate the desks with the company’s information system.

Request the technical brochure now or speak with an expert.

Smart logistics for high productivity lines

The TAV BIP is a dual-level table designed by Graf Synergy to automate the handling of welded components and accessories during the assembly process. With its modular structure and motorised horizontal conveyors, it allows for sorting frames coming from two or more welding lines to different parallel stations, optimising production flows and reducing operator fatigue.

5 Reasons to Choose TAV BIP

- Continuous production without interruptions. Thanks to the two-level system and the intermediate lift, operators can work without having to wait for unloading.

- Scalable layout. Ability to add double-deck stations to increase productivity.

- Integration with Business Systems. Barcode monitors and readers for managing and classifying parts.

- Sturdy and ergonomic structure. Made from bolted aluminium, with extendable benches covered in polythene.

- Automated Handling. Felt carpets powered by electric motors for smooth and safe movement.

Product Details

The TAV BIP is a two-level table designed by Graf Synergy to automate the handling of welded components and accessories during the assembly process. With its modular structure and motorized horizontal conveyors, it allows for sorting frames coming from two or more welding lines to various parallel stations, optimising production flows and reducing operator fatigue.

Machine dimensions (approximate)

Length: to be determined based on configuration

Width: to be defined according to configuration

Height: to be determined based on configuration

Weight: to be determined based on configuration

POWER SUPPLY and Consumption

Installed power: to be defined according to configuration

Voltage: 400 V

Air consumption per cycle: not applicable

Minimum operating pressure: 7 bar

Operational Features

- Transport: motorized fabric carpets

- Composition: modular structure with two-level stations

- Integration: monitor and barcode reader for managing the production flow

- Workstations: from 2 to 5 operators

- Workbenches: featuring hydraulic lift and a surface coated with polythene.

Maximum dimensions for movable frame

- Length: up to 3,200 mm

- Width: up to 2,800 mm

Optional features and available configurations

- Additional double-deck stations for larger production layouts

- Integration with MES software or custom management systems

TECHNOLOGY AND AUTOMATION

TAV BIP is a solution designed to simplify and speed up production logistics. The two-level system allows for the separation of incoming and outgoing flows, while the adjustable-height side benches provide optimal ergonomics for the operator.

Each station is equipped with a visual interface and scanner to ensure traceability and proper classification of parts. The entire system is scalable, customizable, and designed for Industry 4.0 integration.

Contact us to find out if the TAV BIP is the right solution for your production.